Milling Machine Market Anticipated to Grow to USD 110,203.8 Million by 2033

By 2023, the worldwide milling machine market is anticipated to be valued at $68,303.3 million. Between 2023 and 2033, the market is expected to grow at a sluggish but consistent CAGR of 4.9%. The market value is expected to rise to US$ 110,203.8 million by 2033.

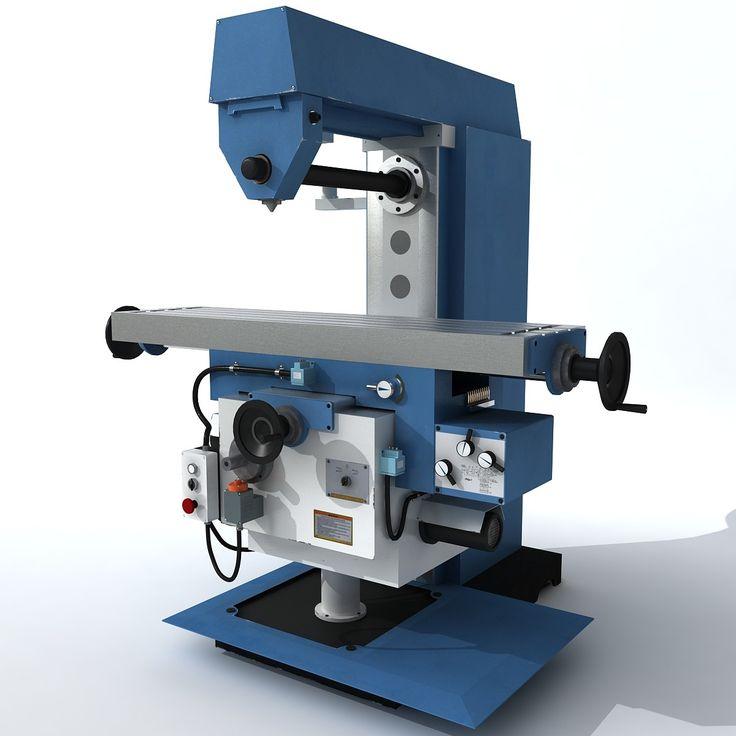

Milling machines are the workhorses of metalworking, capable of carving, drilling, and shaping various metals with precise control. From crafting intricate parts for aerospace components to machining engine blocks for automobiles, milling machines play a vital role in numerous industries. Let's delve into the diverse applications of milling machines and explore the trends propelling this important market forward.

Applications of Milling Machines

Milling machines offer a range of functionalities across various metalworking applications:

- Machining Complex Parts: With their ability to move a cutting tool along multiple axes, milling machines can create intricate three-dimensional shapes in metal components. This is crucial for industries like aerospace, where lightweight and high-precision parts are needed.

- Die and Mold Making: The ability to create precise and polished surfaces makes milling machines ideal for manufacturing dies and molds used in various forming and casting processes.

- Engine Component Production: From machining cylinder heads and engine blocks to creating intricate channels for oil and coolant flow, milling machines are essential for engine manufacturing.

- Job Shops and Contract Manufacturing: Milling machines offer versatility for small-batch production or one-off projects. Job shops and contract manufacturers rely on them to fulfill diverse customer requirements.

- Maintenance and Repair: Machine shops and repair facilities utilize milling machines for machining replacement parts, modifying components, or repairing damaged metal parts.

Get Exclusive Sample Copy of the Report: https://www.futuremarketinsights.com/reports/sample/rep-gb-16589

A Market Fueled by Progress: Growth Factors Shaping the Future

The milling machine market is driven by several key trends:

- Growth in Automotive and Aerospace Industries: The increasing demand for lightweight, high-performance vehicles and complex aerospace components necessitates the use of advanced milling machines for precise part creation.

- Rise of Automation and CNC Technology: The integration of Computer Numerical Control (CNC) technology into milling machines allows for automated and highly precise machining processes, improving efficiency and productivity.

- Demand for Shorter Production Cycles: Manufacturers are constantly striving to reduce time-to-market for new products. Milling machines, with their ability to produce complex parts quickly and accurately, contribute to achieving this goal.

- Growing Focus on Advanced Materials: The increasing use of hard-to-machine materials like titanium alloys and composites in various industries necessitates the development of more powerful and versatile milling machines.

- Skilled Labor Shortage: The growing demand for skilled machinists is a challenge. Milling machines with user-friendly interfaces and automation capabilities can help address this gap to some extent.

The global milling machine market is poised to reach a significant valuation of USD 68,303.3 million by 2023, with an expected CAGR of 4.9% from 2023 to 2033. By the end of the forecast period, the market is anticipated to surge to USD 110,203.8 million.

Challenges and Considerations

While offering significant advantages, the milling machine market faces some challenges:

- High Initial Investment: CNC milling machines, particularly those with advanced features, can involve a significant upfront investment. This can be a barrier for smaller workshops or businesses with limited budgets.

- Skilled Workforce Requirements: Operating and programming CNC milling machines effectively requires a skilled workforce with a strong understanding of machining principles and CNC programming languages.

Rapid Technological Advancements: The milling machine market is constantly evolving with new technologies and features. Keeping pace with these advancements can be challenging for manufacturers and machining professionals.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness