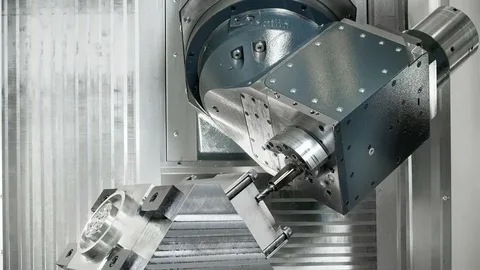

Innovative Trends in 5 Axis CNC Machining Technology

The manufacturing industry continues to evolve with advancements in 5 Axis CNC machining technology. This method has revolutionized precision engineering by enabling more complex part geometries, reducing production times, and increasing efficiency. Businesses that adopt the latest innovations in this area gain a competitive edge in industries like aerospace, automotive, and medical devices. In this article, we will explore the most innovative trends in 5 Axis CNC machining, covering automation, software, tooling, sustainability, and integration with emerging technologies.

Automation and Smart Manufacturing in 5 Axis CNC Machining

Automation has become a driving force in modern 5 Axis CNC machining. Manufacturers are integrating robotic arms and automated pallet changers to enhance machine utilization and minimize downtime. These automated systems allow for continuous, unattended operation, significantly reducing labor costs and human error. With smart sensors and real-time monitoring, operators can track machine performance remotely, ensuring optimal efficiency and reducing unexpected breakdowns.

Furthermore, the rise of Industry 4.0 has brought smart manufacturing concepts to life. Advanced connectivity enables 5 Axis CNC machines to communicate with other equipment and systems in a fully integrated factory setup. This connectivity ensures seamless workflow, predictive maintenance, and better quality control. As automation continues to advance, manufacturers can achieve higher throughput and faster turnaround times, positioning themselves as leaders in precision engineering.

Advanced CAM Software for Complex Part Programming

Modern 5 Axis CNC machining heavily relies on sophisticated Computer-Aided Manufacturing (CAM) software to program intricate tool paths. Unlike traditional 3-axis systems, 5-axis machining requires precise calculations to manage multiple axes simultaneously. Advanced CAM solutions now feature simulation tools that allow engineers to detect collisions, optimize cutting strategies, and ensure flawless machining before production begins. This reduces costly mistakes and enhances accuracy.

Additionally, these software solutions often include AI-driven optimization features. These capabilities analyze cutting conditions and automatically adjust tool paths for maximum efficiency. With user-friendly interfaces and cloud integration, programmers can collaborate from different locations, making the design-to-production process faster and more agile. As CAM technology continues to evolve, 5 Axis CNC machining will become even more precise and adaptable to complex manufacturing challenges.

High-Performance Tooling and Cutting Strategies

Tooling advancements are among the most significant contributors to the evolution of 5 Axis CNC machining. Manufacturers now utilize cutting tools made from advanced materials such as carbide and polycrystalline diamond (PCD) to handle harder materials and improve tool life. These tools reduce wear and tear, resulting in better surface finishes and lower production costs. Coating technologies like Titanium Aluminum Nitride (TiAlN) have also improved heat resistance, allowing for faster cutting speeds without compromising tool integrity.

In addition to tooling innovations, cutting strategies have become more sophisticated. High-speed machining (HSM) techniques enable faster material removal rates, reducing cycle times while maintaining accuracy. Adaptive machining processes adjust cutting parameters in real time based on feedback from the workpiece and the tool, preventing errors and extending tool life. These innovations make 5 Axis CNC machining a go-to solution for industries demanding complex geometries and impeccable precision.

Sustainability and Eco-Friendly Machining Practices

Sustainability has emerged as a crucial factor in modern 5 Axis CNC machining operations. Manufacturers are adopting energy-efficient machines and optimizing workflows to reduce power consumption. Advanced software now calculates the most energy-efficient tool paths, minimizing unnecessary movements and idle times. Furthermore, the integration of regenerative drives helps recover energy during braking, reducing overall operational costs and environmental impact.

Coolant systems have also undergone a green transformation. Many companies are moving towards minimum quantity lubrication (MQL) systems, which drastically reduce coolant usage compared to traditional flood cooling methods. This not only conserves resources but also minimizes disposal issues associated with hazardous fluids. By implementing eco-friendly practices, businesses can maintain profitability while meeting environmental regulations, proving that 5 Axis CNC machining can be both high-performing and sustainable.

Integration with Emerging Technologies: AI, IoT, and Additive Manufacturing

The future of 5 Axis CNC machining lies in its integration with cutting-edge technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and additive manufacturing. AI-driven predictive maintenance helps manufacturers anticipate machine failures before they occur, minimizing downtime and repair costs. IoT connectivity allows machines to share real-time data with central systems, enabling better decision-making and process optimization.

Another groundbreaking trend is the hybridization of additive and subtractive manufacturing processes. By combining 3D printing with 5 Axis CNC machining, manufacturers can produce near-net-shape components and then machine them to precise tolerances. This approach reduces material waste and allows for the creation of complex geometries that were previously impossible with traditional methods alone. These integrations are setting the stage for a new era in manufacturing, where 5 Axis CNC machining works hand in hand with smart technologies for maximum efficiency and innovation.

Conclusion

The world of 5 Axis CNC machining is evolving rapidly, driven by automation, advanced software, high-performance tooling, sustainability initiatives, and integration with next-generation technologies. Companies that embrace these innovative trends will not only stay competitive but also set new benchmarks in precision and efficiency. As these advancements continue, the future of manufacturing promises to be faster, smarter, and more sustainable than ever before.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness