How CNC Turning Services Ensure Tight Tolerances and Consistency

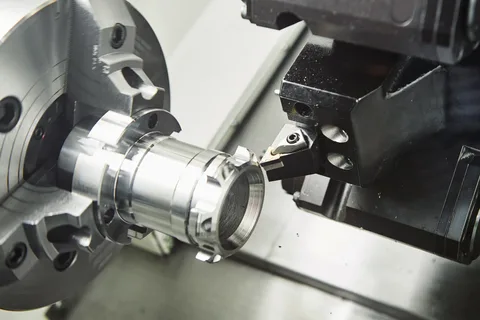

In today’s manufacturing industry, precision is everything. Businesses in automotive, aerospace, electronics, and medical sectors demand components that meet strict dimensional tolerances without compromising quality. This is where CNC Turning Services come into play. CNC turning uses computer numerical control to operate lathes, creating parts with unparalleled accuracy and repeatability.

This article explores how CNC Turning Services maintain tight tolerances and deliver consistent, high-quality components for various industries. We’ll look at advanced technologies, process controls, and quality assurance methods that make CNC turning a top choice for precision machining.

Understanding Tight Tolerances and Why They Matter

Precision machining revolves around the concept of tolerances—the acceptable range of deviation from a specified dimension. In sectors such as aerospace and medical manufacturing, even a slight deviation can lead to part failure, safety risks, or regulatory non-compliance. CNC Turning Services are specifically designed to handle these challenges by providing accuracy down to microns.

Tight tolerances are crucial for ensuring that components fit perfectly within assemblies, maintain structural integrity, and perform reliably under stress. Whether it’s a hydraulic valve or an engine component, the ability to meet stringent dimensional requirements guarantees not only product performance but also brand reputation and customer satisfaction.

The Role of Advanced CNC Technology in Achieving Precision

The backbone of CNC Turning Services lies in state-of-the-art machinery and software integration. Modern CNC lathes come equipped with multi-axis capabilities, allowing for complex geometries and high-precision operations without multiple setups. This minimizes human error and reduces production time while maintaining accuracy.

Additionally, CAD/CAM software integration ensures seamless programming and simulation before production begins. These digital tools eliminate guesswork by allowing engineers to predict machining outcomes, thus minimizing defects. The combination of advanced hardware and software enables CNC Turning Services to produce identical parts consistently across large production runs.

Quality Control Measures for Consistency

Maintaining tight tolerances requires stringent quality control throughout the machining process. CNC Turning Services employ real-time monitoring systems and automated inspection tools to detect deviations instantly. Technologies like Coordinate Measuring Machines (CMM) and in-process probing ensure that each part adheres to the specified dimensions.

Statistical Process Control (SPC) is another key aspect of quality assurance. By collecting and analyzing data during production, manufacturers can identify trends and make adjustments before errors occur. This proactive approach reduces waste, enhances efficiency, and ensures that every part meets the required standards consistently.

Material Selection and Its Impact on Tolerances

The choice of material plays a significant role in achieving and maintaining tight tolerances. Different materials have varying properties such as hardness, thermal expansion, and machinability. CNC Turning Services take these factors into account when planning operations. For example, metals like titanium require specialized tooling and cutting speeds to prevent warping or dimensional changes.

Advanced CNC systems also compensate for temperature fluctuations that could affect material stability during machining. By adjusting feed rates, spindle speeds, and coolant flow, these systems maintain accuracy even when dealing with challenging materials. This adaptability ensures consistency, regardless of material complexity or batch size.

Benefits of Partnering with Professional CNC Turning Services

Choosing professional CNC Turning Services offers numerous advantages beyond precision. Businesses gain access to skilled technicians, advanced equipment, and robust quality control systems that may not be feasible to maintain in-house. This not only guarantees tight tolerances but also reduces overhead costs associated with equipment maintenance and labor.

Moreover, outsourcing to reliable CNC experts enhances scalability. Whether you need small prototypes or high-volume production, professional services deliver consistent quality at every stage. Their ability to meet deadlines while adhering to strict specifications gives businesses a competitive edge in today’s fast-paced market.

Conclusion

In an era where precision determines success, CNC Turning Services have become indispensable for industries that demand accuracy and consistency. By leveraging advanced machinery, rigorous quality control, and expert knowledge, these services ensure that every component meets exacting standards.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness