Industrial Valve Market in Industrial Processing

The Industrial Valve Market, as detailed in the Industrial Valve Market report, is deeply intertwined with the industrial processing landscape. From chemicals and petrochemicals to food and pharmaceuticals, industrial processing relies on valves to regulate, direct, and control the flow of liquids, gases, and slurries. With advancements in automation, materials science, and sustainability, the valve market is poised to drive efficiency and innovation across process industries.

1. Role of Valves in Industrial Processing

Valves are essential to industrial processing for their capability to:

-

Control flow: Start, stop, or throttle material flow.

-

Maintain pressure: Control and relieve pressure to ensure safety.

-

Segment processes: Isolate sections for maintenance or safety.

-

Regulate temperature and mixing: Manage steam, injectants, or catalysts precisely.

These functions support continuous production, safety protocols, and product consistency across plants.

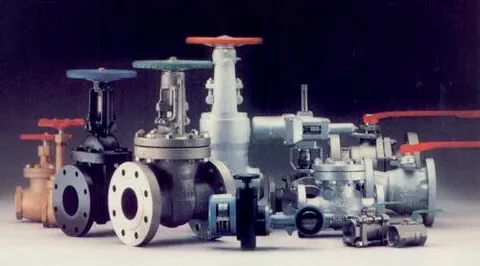

2. Types of Valves Commonly Used

Industrial processing employs various valve types:

-

Ball valves: Provide tight shut-off with minimal leakage—widely used in water, gas, and chemical service.

-

Globe valves: Offer precise throttling, ideal for regulating flow and maintaining pressure.

-

Butterfly valves: Lightweight and cost-effective, commonly used in large pipelines for HVAC, water, and wastewater.

-

Diaphragm valves: Hygienic and simple to clean, popular in food, beverage, and biotech industries.

-

Check valves: Prevent backflow and protect pumps and compressors.

-

Plug valves: Used in on/off and throttling services, particularly in chemical and petrochemical environments.

The chosen valve depends on factors like flow characteristics, media type, pressure, temperature, and maintenance requirements.

3. Integration with Automation and Control

A major trend in industrial processing is the integration of valves into automation systems like SCADA, DCS, and IIoT platforms. Smart valves, fitted with sensors, provide real-time data on pressure, flow, and temperature trends. Key benefits include:

-

Remote monitoring and control: Operators can adjust valves from centralized control rooms.

-

Predictive and condition-based maintenance: Data analytics detect wear or leaks before failure.

-

Process optimization: Automated valve adjustments maintain consistent product quality and energy efficiency.

-

Enhanced safety: Immediate shutdown upon detecting unsafe conditions, such as overpressure or leaks.

This level of integration ensures smoother operations and higher asset reliability in processing plants.

4. Materials and Durability

Valves in industrial processing must withstand challenging environments—high pressure, elevated temperatures, and/or corrosive chemicals. Innovative materials and coatings include:

-

Stainless steel and duplex alloys: For corrosion protection in aggressive media.

-

PTFE, PFA, and rubber linings: For chemical resistance and clean operation.

-

High-performance polymers: For lower friction, lightweight construction, and reduced wear.

-

Advanced surface treatments: Nano-coatings or electroplating to resist abrasion and corrosion.

These materials enhance component lifespan and reduce the frequency and cost of shutdowns for repairs.

5. Design for Cleanability and Hygiene

Food, beverage, pharmaceutical, and biotech plants require hygienic valve designs to meet safety standards:

-

Diaphragm valves: Avoid crevices and dead zones, facilitating clean-in-place (CIP) and sterilize-in-place (SIP) processes.

-

Tri-clamp ball valves: Disconnectable for easy cleaning or replacement.

-

Polished finishes and FDA-grade seals: Prevent contamination and support full traceability.

Ensuring easy sanitization and documentation helps plants maintain high standards of safety and quality.

6. Leak Minimization and Emissions Control

Environmental compliance and worker safety demand valves with low fugitive emissions. Innovations include:

-

Double-packing, bellows seals, and metal-to-metal seating to prevent leaks.

-

Leak detection sensors integrated into the valve body or packing.

-

Automated valve shutdowns in case of detected leaks.

These features align with environmental regulations and reduce costs associated with product loss and safety incidents.

7. Energy Efficiency and Sustainability

Valves play a key role in conserving energy and lowering the carbon footprint in industrial processes:

-

Throttling efficiencies minimize pressure drops and reduce pump energy use.

-

Smart control adjusts valve performance to match real-time process demands, avoiding waste.

-

Eco-design principles reduce valve material and promote recyclability at end of life.

These measures support ESG goals and offer long-term savings through reduced energy usage and carbon emissions.

8. Challenges and Solutions

Industrial processing environments present several challenges:

-

Corrosion and erosion from aggressive chemicals or slurries.

-

Thermal cycling and fatigue due to changing process conditions.

-

Instrumentation compatibility for smart valve data integration.

-

Downtime during valve maintenance.

Valve suppliers address these through robust material selection, modular designs for easy retrofitting, and predictive analytics tools that signal required maintenance before breakdown.

9. Future Outlook

The future of valves in industrial processing will be shaped by:

-

Widespread deployment of smart valve networks across processing facilities.

-

AI-powered process control, using valve data to optimize entire manufacturing flows.

-

Collaborative equipment integration—valves paired with pumps, sensors, and control valves for optimized sub-systems.

-

Green certifications and standards compliance, making low-emission valves a standard part of plant upgrades and new builds.

These developments will increase automation, reduce costs, and improve the sustainability of processing operations.

Conclusion

Valves are no longer passive flow controllers they’ve become smart, resilient, and essential components in industrial processing. By embracing automation, durability, hygiene, and eco-design, valve manufacturers are responding to the evolving needs of the process industries.

As industries continue modernizing with stricter environmental regulations, higher automation standards, and sustainability targets the Industrial Valve Market will be critical in shaping the future of fluid and gas control in production plants around the world.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness