Evaluating the Durability of FFC Ribbon Cable Under Repeated Plugging and Unplugging

The ability of an FFC Ribbon Cable to endure multiple insertion and removal cycles is a key concern for many electronic applications, especially those involving frequent maintenance, upgrades, or modular designs. Unlike fixed wiring solutions, FFC Ribbon Cables are often used with connectors that allow easy connection and disconnection. However, repeated plugging and unplugging can impose mechanical stress on both the cable and its connectors, potentially affecting their longevity and performance. Whether an FFC Ribbon Cable can handle multiple cycles without degradation depends on several factors, including the quality of the cable, the type of connectors used, and the handling practices.

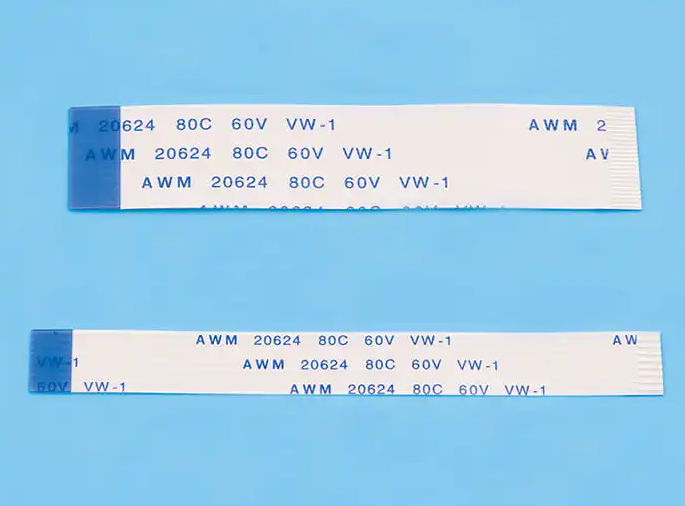

FFC Ribbon Cable itself is composed of flat copper conductors laminated between insulating films such as polyester or polyimide. While the cable is flexible and designed for space-saving routing, the cable alone is not directly subjected to insertion forces; these forces mostly affect the connectors at each end. The connectors, often zero insertion force (ZIF) or low insertion force (LIF) types, are designed to minimize wear on the cable during repeated connections. A properly matched connector system can allow for hundreds or even thousands of mating cycles without significant damage, provided the cable and connectors are handled carefully.

The durability of the connection interface is essential. Connectors that use locking mechanisms or friction fit are designed to ensure secure electrical contact but also to reduce stress on the cable. High-quality connectors prevent damage to the delicate flat conductors and insulating layers of the FFC Ribbon Cable by applying minimal insertion force while maintaining stable connections. Poorly designed or incompatible connectors may cause the cable to bend excessively, crease, or wear, which could lead to conductor breakage or loss of insulation integrity over time.

Material selection also plays a role in how well the cable withstands multiple insertions. Polyimide-insulated FFC Ribbon Cables tend to have better mechanical strength and durability compared to polyester-based alternatives. This enhanced durability helps the cable resist mechanical fatigue from bending and flexing that may occur near the connection points during repeated plug cycles.

In addition to mechanical considerations, repeated insertion and removal can also impact the electrical reliability of the cable assembly. Oxidation or contamination at the contact points can degrade signal transmission, so connectors often use gold plating or other corrosion-resistant finishes to maintain low-resistance, stable connections over many cycles. Proper maintenance and clean handling further extend the lifespan of the cable and connectors.

In practical terms, many manufacturers specify the number of insertion cycles their FFC Ribbon Cable assemblies can endure, which typically ranges from several hundred to a few thousand cycles, depending on the quality and application. For critical applications where frequent disconnections are expected, choosing cables and connectors rated for high mating cycles is essential to avoid premature failure.

In conclusion, FFC Ribbon Cable can be used for multiple insertions and removals if paired with appropriate connectors and handled with care. The cable itself is designed to be flexible and durable, but the connector interface plays the largest role in determining how many cycles the assembly can withstand. Selecting high-quality components and following recommended handling procedures ensures reliable performance and longevity even in applications requiring repeated connections.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness