Emerging Trends Shaping the Future of Injection Molding Machines

The injection molding machine industry is embracing new trends to meet the demands of a rapidly evolving manufacturing landscape. From digital transformation to sustainability, the next generation of machines is smarter, cleaner, and more versatile.

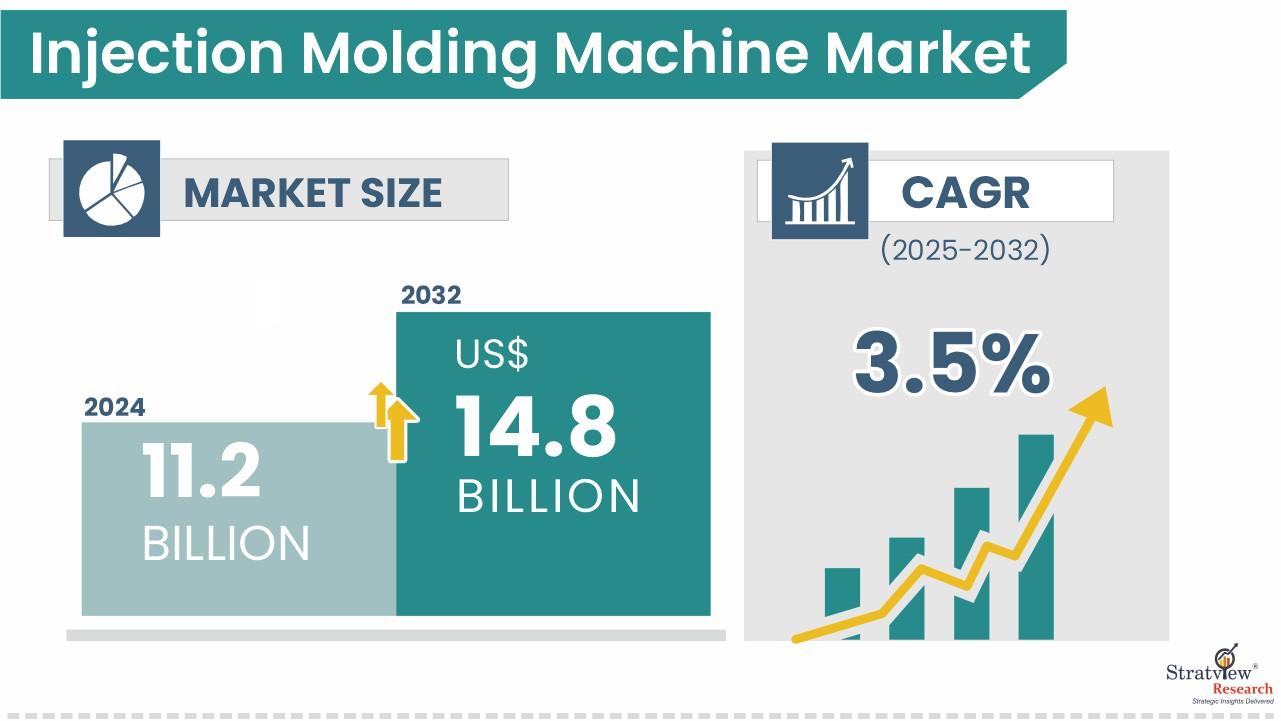

According to Stratview Research, the injection molding machine market was estimated at USD 11.2 billion in 2024 and is likely to grow at a CAGR of 3.5% during 2025-2032 to reach USD 14.8 billion in 2032.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/1146/injection-molding-machine-market.html#form

Top Trends:

- All-Electric Machines: These are replacing hydraulic machines due to better energy efficiency, speed, and precision.

- Industry 4.0 Integration: Real-time data analytics, AI-based process optimization, and remote diagnostics are transforming how machines operate.

- Compact and Modular Designs: Space-saving and portable machine variants are enabling flexible production in tight spaces.

- Multi-Material Molding: Technologies such as co-injection and multi-shot molding allow manufacturers to combine different materials in a single process.

Driving Forces Behind These Trends:

- Sustainability Mandates: Regulatory pressure is encouraging the development of greener machinery.

- Rising Labor Costs: Automation and remote operation help reduce dependency on manual intervention.

- Customization Demand: Short product cycles and personalized products are driving demand for flexible, quick-change machines.

Conclusion:

As the injection molding machine market adopts cutting-edge technologies, it’s becoming leaner, smarter, and more aligned with the needs of modern manufacturing. Those who invest in the latest trends will gain a competitive edge.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness