Glass Lined Heat Exchangers Market Grows with Eco-Safe Solutions

Glass Lined Heat Exchangers Market is growing due to rising demand for corrosion-resistant solutions in chemical and pharma industries ensuring safe heat transfer in harsh environments.

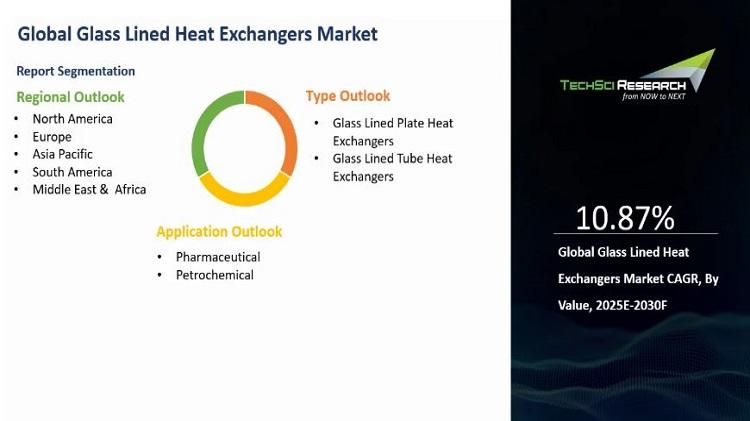

According to the TechSci Research report titled “Glass Lined Heat Exchangers Market – Global Industry Size, Share, Trends, Competition Forecast & Opportunities, 2030F,” the global Glass Lined Heat Exchangers Market was valued at USD 1.07 billion in 2024 and is projected to reach USD 2.01 billion by 2030, growing at a CAGR of 10.87% during the forecast period.

The market is witnessing strong growth, primarily driven by increasing demand from industries that require highly corrosion-resistant and contamination-free heat transfer solutions. Glass lined heat exchangers (GLHEs) are particularly valued in sectors such as chemicals, pharmaceuticals, petrochemicals, and food & beverage for their ability to maintain product integrity and withstand highly reactive, acidic, or caustic substances.

Key Market Drivers

In the chemical industry, where processes often involve aggressive and corrosive substances, GLHEs offer essential advantages in maintaining purity and ensuring operational safety. These exchangers are preferred for their resistance to corrosion and long operational life, reducing the risk of product contamination. The ongoing global expansion of chemical manufacturing, particularly in emerging economies, continues to fuel market demand as companies invest in upgrading their process infrastructure.

The pharmaceutical industry is another major contributor to GLHE market growth. The need for high levels of hygiene, cleanliness, and precise thermal control in pharmaceutical production makes glass lined heat exchangers a vital part of equipment in drug manufacturing facilities. The non-reactive nature of the glass lining helps preserve the chemical composition of pharmaceutical products, ensuring safety and efficacy. Rising healthcare needs, increasing R&D investments, and expanding production capacity—especially in emerging markets—are key factors boosting adoption in this segment.

In the food and beverage sector, glass lined heat exchangers play a critical role in applications such as pasteurization, sterilization, and controlled heating or cooling of sensitive ingredients. Their ability to resist acidic or alkaline substances and maintain sanitary processing conditions aligns well with regulatory standards and growing consumer expectations for safe, high-quality food products.

The petrochemical industry also relies heavily on heat exchangers that can handle high pressures and aggressive chemicals. Glass lined variants are particularly suited for processes involving volatile substances or temperature-sensitive reactions. As global demand for petrochemical products continues to grow due to industrial expansion and urbanization, the need for durable, low-maintenance equipment like GLHEs becomes even more pressing.

Technological Innovations and Sustainability Trends

Advancements in materials science and manufacturing techniques are further boosting the performance of glass lined heat exchangers. Improvements in glass-lining technologies have led to greater resistance to mechanical stress and thermal shock. This has made the latest GLHE models more suitable for high-demand applications where older equipment would have struggled.

The integration of smart technologies, including IoT-enabled sensors and remote monitoring systems, is transforming how glass lined exchangers are managed and maintained. These systems enable real-time diagnostics, predictive maintenance, and more efficient process control, helping industrial users reduce downtime and extend equipment life.

As environmental concerns and energy efficiency become central to industrial decision-making, GLHEs offer several sustainability advantages. Their superior thermal performance helps reduce energy consumption in heating and cooling processes. Their long operational life and minimal maintenance needs also reduce resource consumption and waste over time.

Market Segmentation Insights

By Application: Pharmaceutical Segment Leads

In 2024, the pharmaceutical segment held the largest share of the global Glass Lined Heat Exchangers Market. This dominance is attributed to the industry's stringent requirements for hygiene, precision, and process integrity. The non-porous, chemically inert surface of glass prevents contamination and facilitates easy cleaning, making it ideal for pharmaceutical applications.

Moreover, as global pharmaceutical production increases to meet rising healthcare needs, manufacturers are upgrading facilities to comply with international standards. Glass lined heat exchangers help meet these requirements by offering a safe and efficient means of heat transfer for chemically sensitive compounds. Additionally, regulatory pressure on pharmaceutical companies to maintain clean production environments further drives demand for GLHEs.

Sustainability goals are also reshaping the pharmaceutical industry. Many manufacturers are now emphasizing energy-efficient and long-lasting process equipment to align with corporate responsibility initiatives and regulatory standards. Glass lined exchangers support these efforts with their high thermal efficiency and reduced environmental footprint.

Browse over XX Market data Figures spread through XX Pages and an in-depth TOC on the "Global Glass Lined Heat Exchangers Market.”

https://www.techsciresearch.com/report/glass-lined-heat-exchangers-market/29432.html

Regional Insights: Asia Pacific Emerges as Growth Leader

The Asia Pacific region is projected to be the fastest-growing market for glass lined heat exchangers during the forecast period. Countries such as China, India, Japan, and several Southeast Asian nations are witnessing rapid industrialization, coupled with growing investments in manufacturing infrastructure.

Strong growth in regional chemical, pharmaceutical, and food processing industries is fueling demand for advanced heat exchanger technologies that can operate reliably in aggressive environments. Furthermore, governments across Asia Pacific are implementing stricter environmental and safety regulations, encouraging industries to adopt more efficient and compliant technologies like GLHEs.

Additionally, increasing foreign direct investment (FDI) and the expansion of export-oriented manufacturing activities are driving demand for high-quality, durable process equipment. Local manufacturers are also entering the market, offering cost-effective glass lined solutions tailored to regional requirements, further enhancing the region’s competitiveness.

Conclusion

The global Glass Lined Heat Exchangers Market is on a strong upward trajectory, driven by a mix of industrial expansion, technological innovation, and regulatory push across key sectors. With increasing emphasis on energy efficiency, product purity, and sustainable manufacturing practices, the demand for glass lined heat exchangers is set to rise significantly.

Industries across the globe are recognizing the long-term operational and economic benefits of adopting GLHEs, particularly in chemically demanding and contamination-sensitive processes. Supported by ongoing advancements and expanding regional markets, the glass lined heat exchanger market is well-positioned for sustained growth through 2030 and beyond.

Major companies operating in the Global Glass Lined Heat Exchangers Market are:

De Dietrich Process Systems

Borosil Glass Works Ltd.

Halvorsen AS

Thermotech Inc.

Klaus Union GmbH & Co. KG

Paques B.V.

Mather & Platt Group

Menzel GmbH

Liqtech International A/S

Parsons Corporation

Download Free Sample Report

https://www.techsciresearch.com/sample-report.aspx?cid=29432

Customers can also request 10% free customization in this report.

“The Global Glass Lined Heat Exchangers Market is expected to rise in the upcoming years and register a significant CAGR during the forecast period. The Glass Lined Heat Exchangers Market is witnessing strong growth, propelled by rising demand for corrosion-resistant and high-efficiency heat transfer solutions across key industrial sectors. Expansion in chemical processing, pharmaceuticals, and food & beverage industries is driving market momentum. Technological advancements in glasslining enhance product durability and performance, further supporting market development.

Additionally, accelerating industrialization and increased focus on energy-efficient processes in emerging economies are creating substantial opportunities. These factors collectively position the market for sustained growth and innovation in delivering reliable, high-performance heat exchanger solutions. Therefore, the Market of Glass Lined Heat Exchangers is expected to boost in the upcoming years.,” said Mr. Karan Chechi, Research Director of TechSci Research, a research-based global management consulting firm.

“Glass Lined Heat Exchangers Market - Global Industry Size, Share, Trends, Opportunity, and Forecast, Segmented, By Type (Glass Lined Plate Heat Exchangers, Glass Lined Tube Heat Exchangers), By Application (Pharmaceutical, Petrochemical), By Region, By Competition, 2020-2030F”, has evaluated the future growth potential of Global Glass Lined Heat Exchangers Market and provides statistics & information on the Market size, structure, and future Market growth. The report intends to provide cutting-edge Market intelligence and help decision-makers make sound investment decisions., The report also identifies and analyzes the emerging trends along with essential drivers, challenges, and opportunities in the Global Glass Lined Heat Exchangers Market.

Contact

Techsci Research LLC

420 Lexington Avenue,

Suite 300, New York,

United States- 10170

Tel: +13322586602

Email: sales@techsciresearch.com

Website: www.techsciresearch.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness