The Advantages of Cell-to-Pack Battery Technology in Electric Vehicle Manufacturing

The global shift towards electric vehicles (EVs) is accelerating, with advancements in battery technology playing a crucial role in this transformation. One such innovation is the cell-to-pack (CTP) technology, which integrates battery cells directly into the pack, eliminating the need for intermediate modules. This development offers several advantages in terms of performance, cost reduction, and vehicle efficiency, making it a key technology in the electric vehicle market.

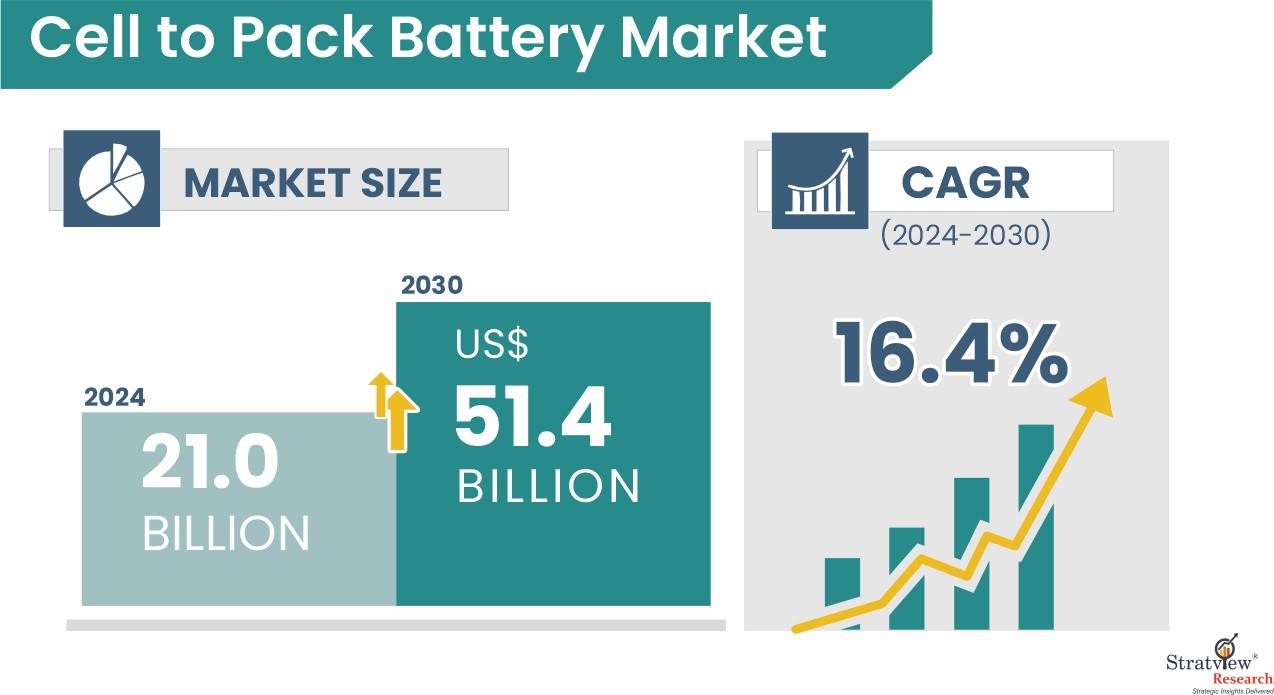

Stratview Research reports that the cell-to-pack battery market is set to grow at a CAGR of 16.4% and is expected to reach USD 51.4 billion by 2030 driven by increasing demand for high-performance EVs and advancements in battery technology.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/4117/cell-to-pack-battery-market.html#form

How Cell-to-Pack Technology Works

In traditional battery designs, individual cells are grouped into modules, which are then assembled into packs. With cell-to-pack technology, the cells are integrated directly into the pack, without the need for modules. This design eliminates unnecessary components and reduces the overall weight and cost of the battery pack, while improving energy density.

Key Advantages of Cell-to-Pack Technology

- Improved Energy Density:

CTP technology significantly increases the energy density of batteries by eliminating modules and optimizing the use of available space within the pack. This leads to longer ranges for electric vehicles without compromising on size or weight. - Lower Manufacturing Costs:

By reducing the number of components, cell-to-pack systems lower manufacturing costs. The simplified design makes it easier for manufacturers to produce batteries on a larger scale, further driving cost efficiency in the EV market. - Enhanced Thermal Management:

With fewer components and a more integrated design, CTP battery packs improve thermal management. Better heat dissipation enhances the safety and performance of electric vehicles by reducing the risk of overheating.

Market Opportunities for Cell-to-Pack Batteries

- Growing Demand for EVs:

As electric vehicle adoption grows globally, manufacturers are under pressure to deliver cost-effective, high-performance EVs. Cell-to-pack technology is well-positioned to meet these needs by offering better energy efficiency and lower manufacturing costs. - Focus on Sustainability:

With increasing pressure to reduce carbon footprints, sustainable transportation solutions like electric vehicles are gaining traction. CTP technology supports sustainable mobility by improving battery performance and reducing waste in the production process.

Challenges and Considerations

- Compatibility with Existing EV Designs:

Integrating cell-to-pack technology into existing EV platforms requires careful design considerations to ensure compatibility with current vehicle architecture and battery systems. - Manufacturing Scalability:

The scalability of CTP battery production is a critical factor. Manufacturers must invest in scalable production techniques to meet the growing demand for electric vehicles without compromising on cost or quality.

Conclusion

Cell-to-pack battery technology represents a significant breakthrough in electric vehicle manufacturing, offering improved efficiency, cost savings, and sustainability. As the market continues to grow, this technology will play a key role in the advancement of EVs and the future of transportation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness