Choosing the Right Taper Shank Drill for the Job

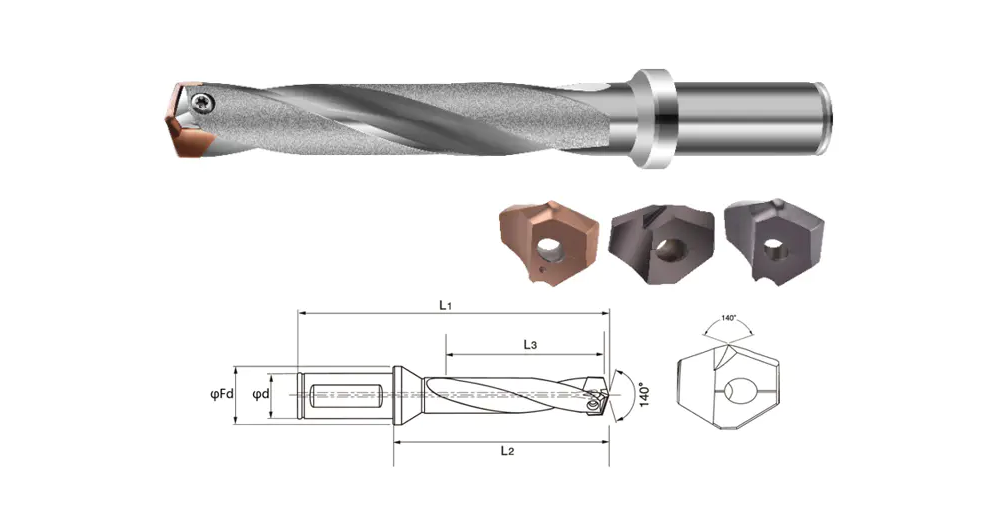

Taper shank twist drills are commonly found in professional machine shops, maintenance operations, and manufacturing lines. Their tapered ends provide a snug fit into spindles and sleeves, eliminating the need for drill chucks in many cases. This design allows for smooth torque transfer and minimized misalignment during drilling.

In terms of application, taper shank twist drills are often used for boring holes in metal workpieces. They are particularly useful in industrial environments that demand precision and repeatability. With a variety of lengths and diameters available, these tools are adaptable to a broad range of hole depths and sizes.

Material choice is also a factor in selecting the right taper shank drill. Commonly produced from high-speed steel, cobalt alloys, or carbide-tipped versions, these drills cater to different hardness levels. The specific geometry of the cutting edges and flutes enhances the drill’s ability to evacuate chips and maintain cutting performance under pressure.

One advantage of the taper connection is ease of tool removal. After use, a simple drift wedge can be employed to separate the drill from the spindle or sleeve. This feature is especially beneficial in setups where drills must be changed frequently without time-consuming adjustments.

Operators need to pay attention to machine compatibility when using taper shank twist drills. Matching the taper size and angle with the receiving component ensures tight engagement and consistent results. Inadequate fit may lead to vibration, inaccurate drilling, or even tool damage.

These drills also see frequent use in operations involving large-scale parts where handheld tools are ineffective. With proper clamping and feed control, the tool can achieve smooth entry and uniform hole walls. Cooling fluids can be introduced to extend tool life and reduce wear.

Taper shank twist drills continue to play a significant role in drilling applications due to their design advantages and reliable function. Their ability to fit securely into machines and offer precise performance makes them a go-to option across many industrial sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness