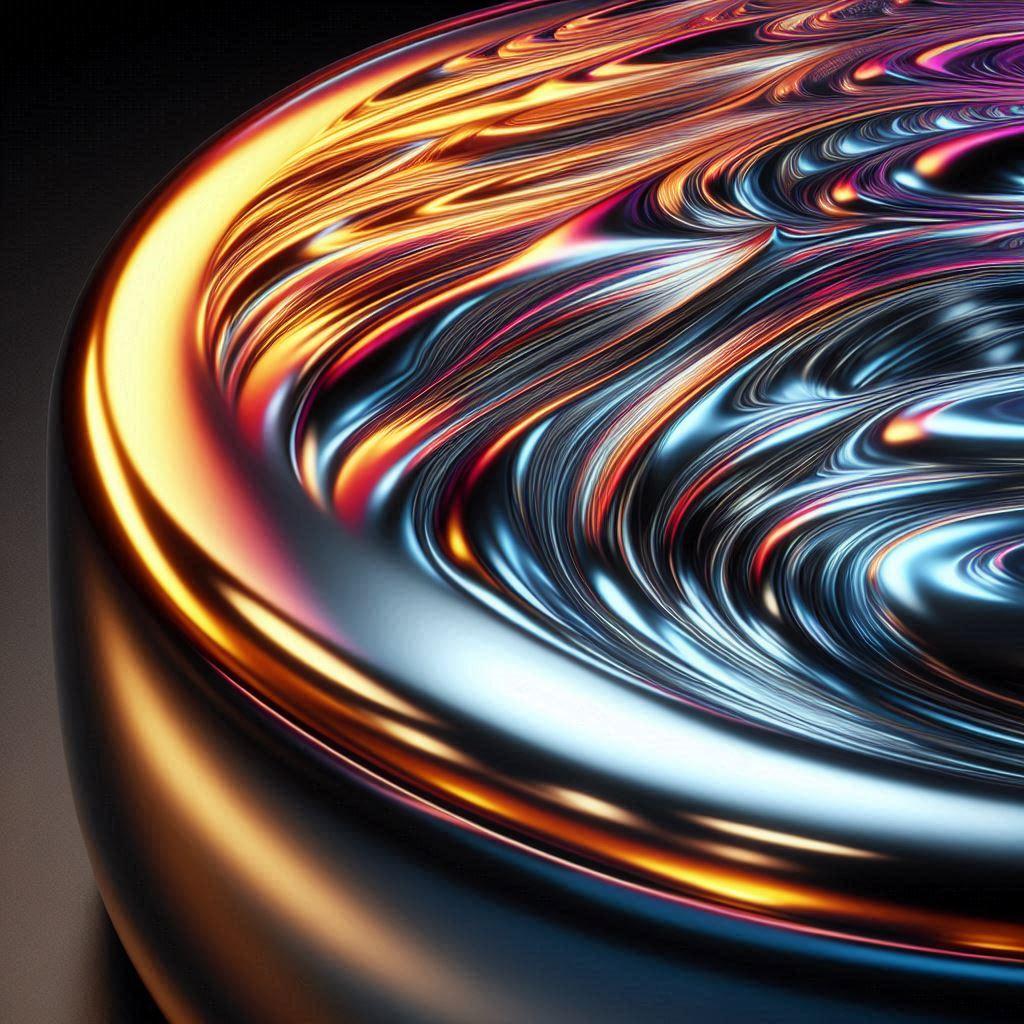

Trivalent Chromium Finishing Market Insights by Region and Application 2033

The global trivalent chromium finishing market reached a value of US$ 370 million in 2023 and is projected to grow to US$ 665 million by 2033, expanding at a compound annual growth rate (CAGR) of 6% over the forecast period. The rising adoption of this environmentally friendly coating technology is largely driven by tightening global regulations against the use of hexavalent chromium, which is considered highly toxic and carcinogenic.

Trivalent chromium finishing offers an attractive solution in surface finishing by ensuring regulatory compliance without compromising on performance. As sustainability becomes a central theme in manufacturing, demand for this eco-compliant plating method is rising steadily. Companies across sectors are investing in the technology as part of their environmental, social, and governance (ESG) commitments, and this shift is expected to fuel further market expansion globally.

For More Insights, Request a Sample of this Report:

https://www.factmr.com/connectus/sample?flag=S&rep_id=7892

Market Analysis

Environmental regulations have become one of the most significant growth drivers in the trivalent chromium finishing market. The regulatory ban and phased restrictions on hexavalent chromium by the U.S. Environmental Protection Agency (EPA) and European REACH directives have prompted manufacturers to adopt trivalent chromium-based coatings, especially in regions with strict industrial compliance frameworks. This has led to widespread substitution in applications that historically relied on hexavalent plating, particularly in automotive trims, aerospace components, and industrial machinery. Another factor supporting market expansion is the rising demand for higher durability and corrosion-resistant finishes that can extend the life cycle of products. Trivalent chromium coatings provide strong resistance to corrosion and wear while reducing energy consumption during the plating process.

Segment Analysis

The trivalent chromium finishing market is segmented by plating type, base material, and end-use industry. Decorative plating continues to dominate due to its extensive use in vehicle interiors, household fixtures, and consumer electronics. This segment benefits from both aesthetic appeal and compliance advantages, making it the preferred option for many consumer-facing products. Functional plating, although smaller in size, is growing rapidly in specialized sectors such as aerospace and industrial manufacturing where mechanical performance and corrosion resistance are critical.

Steel is the leading base material in this market, owing to its broad usage in structural applications and its compatibility with trivalent chromium coatings. Aluminum and plastic substrates are also gaining traction, particularly in automotive and electronics, due to weight reduction trends and component miniaturization. Among end-use industries, the automotive sector leads the market, with extensive applications in bumpers, grills, trims, and wheels.

Country-wise Insights

In the United States, the trivalent chromium finishing market is projected to grow at a CAGR of 5.8% through 2033. The country has witnessed a significant shift in surface finishing technologies following the EPA’s stringent stance on hexavalent chromium. Key industries such as automotive manufacturing and aerospace maintenance, repair, and overhaul (MRO) are adopting trivalent chromium to meet compliance standards and improve operational efficiency.

The United Kingdom has also demonstrated steady adoption, supported by the transition to eco-friendly industrial practices following Brexit and the retention of REACH-aligned regulatory frameworks. Growth in the U.K. market is forecast at a CAGR of approximately 5.5%, driven by demand in the automotive aftermarket and the plumbing sector, both of which benefit from the combination of visual quality and material durability offered by trivalent coatings.

Key Players

- MacDermid Incorporated

- Atotech

- Sarrel Group

- Chem Processing, Inc.

- Ronatec C2C, Inc.

- Electro Chemical Finishing

- Kakihara Industries Co., Ltd.

- Asterion LLC

- Columbia Chemical

- Midland Polishing and Plating Ltd.

Strategic Outlook and Industry Trends

The strategic direction of the market is heavily influenced by the ongoing push for sustainability and innovation in surface engineering. Companies are not only upgrading existing plating lines but also partnering with raw material suppliers and technology providers to ensure a reliable and compliant production chain. Efforts are underway to integrate energy-efficient and low-emission technologies into plating systems, which is expected to drive future competitiveness.

Another emerging trend is the adoption of digital tools for process monitoring and control, enhancing product consistency and reducing waste. In addition, manufacturers are exploring hybrid finishes and nano-enhanced coatings that further improve performance metrics such as hardness, gloss retention, and resistance to abrasion.

Segmentation of Trivalent Chromium Finishing Market

By Plating Type

- Decorative Plating

- Functional Plating

By Base Material

- Steel

- Aluminum

- Plastic

By End-Use Industry

- Automotive

- Aerospace

- Electronics

- Plumbing

- Heavy Equipment

By Region

- North America

- Europe

- East Asia

- South Asia & Oceania

- Latin America

- Middle East & Africa

Explore More Related Studies Published by Fact.MR Research:

Plastics in Personal Protective Equipment Market

Polychlorotrifluoroethylene Market

Contact:

US Sales Office

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

Email: sales@factmr.com

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness