Electrically Conductive Adhesives Market Demand Rising Due to High-Tech Electronics and EV Innovations

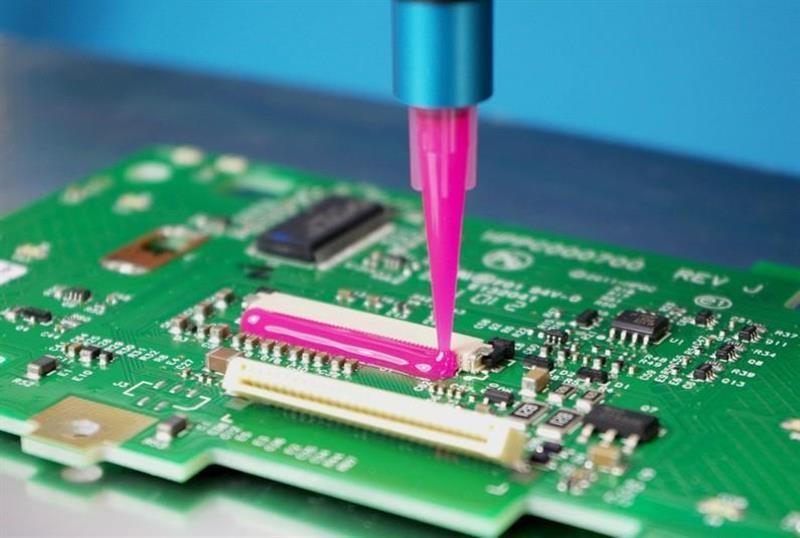

The electrically conductive adhesives market is experiencing a significant surge in demand, spurred by rapid advancements in electronics, automotive, healthcare, and renewable energy sectors. As industries increasingly prioritize performance, miniaturization, and sustainability, these specialized adhesives have emerged as essential solutions, replacing traditional soldering methods and enabling the seamless integration of electrical and mechanical components.

Electrically conductive adhesives (ECAs) offer a unique combination of electrical conductivity, structural bonding, and thermal management. These characteristics are especially important in today’s era of compact devices, where conventional soldering can be limiting due to heat sensitivity and substrate compatibility issues. As such, the market is witnessing robust growth, with demand expected to continue rising across multiple verticals.

Driving Demand in Advanced Consumer Electronics

One of the primary contributors to the growing demand for ECAs is the consumer electronics industry. As devices become smarter, thinner, and more powerful, manufacturers require bonding solutions that can support densely packed, complex circuitry without compromising reliability or safety. ECAs offer a low-temperature alternative to soldering, enabling better bonding on temperature-sensitive substrates like plastics or flexible films.

This demand is further intensified by the global popularity of smart wearables, wireless devices, and foldable screens. Electrically conductive adhesives allow for more flexible design possibilities, enabling producers to meet the market’s expectations for innovation and user-friendly functionality. As newer generations of devices continue to prioritize performance and aesthetics, demand for ECAs will remain strong.

Electric Vehicles and Automotive Electronics Fueling Demand

The electric vehicle (EV) revolution is another major force accelerating the demand for ECAs. Modern vehicles, especially EVs and hybrid models, incorporate a multitude of sensors, battery systems, and control modules. These components require reliable electrical and thermal connectivity, even under extreme environmental conditions such as heat, vibration, and moisture.

ECAs are increasingly being adopted in place of traditional solder joints due to their resilience, ease of application, and ability to bond dissimilar materials. Their use in assembling lithium-ion battery modules, infotainment systems, and ADAS (Advanced Driver Assistance Systems) is becoming standard practice, driving sustained market demand from the automotive sector.

Medical and Healthcare Applications Enhancing Market Demand

The healthcare sector’s growing adoption of electronic devices is also boosting the need for electrically conductive adhesives. These adhesives are widely used in diagnostic instruments, biosensors, and wearable health monitors. As healthcare becomes more digitized and personalized, the demand for compact, reliable, and skin-friendly adhesive solutions is on the rise.

ECAs offer advantages such as biocompatibility and low curing temperatures, making them suitable for sensitive medical applications. From ECG sensors to implantable devices and drug delivery systems, the market is seeing growing demand for adhesives that ensure both electrical functionality and patient safety.

Increased Use in Renewable Energy and Smart Infrastructure

The demand for ECAs is also being fueled by the expansion of renewable energy technologies and smart infrastructure projects. In solar panels, wind turbines, and energy storage systems, ECAs are used for bonding and interconnecting components where long-term electrical performance is critical.

Smart cities and connected infrastructure projects rely heavily on sensors and embedded electronics. ECAs play a vital role in assembling and maintaining these systems, especially in applications where traditional soldering is impractical due to heat or environmental exposure. As governments and corporations invest more in energy-efficient technologies and infrastructure upgrades, the market for conductive adhesives will continue to expand.

Material Advancements and Product Innovations

Another factor boosting demand is ongoing innovation in material science. Manufacturers are developing new adhesive formulations that combine superior conductivity, enhanced thermal stability, and environmental resistance. Silver-based adhesives dominate the market due to their high conductivity, but alternatives like carbon and graphene-based adhesives are gaining attention due to their lower cost and sustainability potential.

Moreover, product customization is enabling companies to offer ECAs tailored for specific end-use applications, such as pressure-sensitive or UV-curable variants. These innovations not only meet the increasing technical demands of OEMs but also attract new users looking for efficient, scalable solutions.

Asia-Pacific Emerges as a Demand Hub

Geographically, the Asia-Pacific region accounts for the highest demand, owing to its leadership in electronics manufacturing, automotive production, and technological innovation. Countries like China, Japan, South Korea, and Taiwan are major contributors, housing some of the largest global OEMs and component manufacturers.

The growing domestic demand for consumer electronics, electric vehicles, and advanced industrial automation in these countries further reinforces the need for high-performance electrically conductive adhesives. As regional governments support industrial growth through policies and investments, demand in Asia-Pacific is expected to remain dominant.

Conclusion

The increasing demand for electrically conductive adhesives is being driven by a combination of technology shifts, industry-specific innovations, and changing consumer expectations. From enabling ultra-slim electronics to supporting sustainable transportation and personalized healthcare, ECAs are becoming indispensable across diverse industries.

Their advantages over traditional bonding methods—including flexibility, conductivity, and environmental compatibility—position them as the bonding solution of the future. As more industries embrace advanced materials and design strategies, the demand for electrically conductive adhesives is set to rise even further, unlocking new market opportunities and fostering long-term growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness