Soft Magnetic Material Market Innovations Boosted by Research in Amorphous and Nanocrystalline Alloys

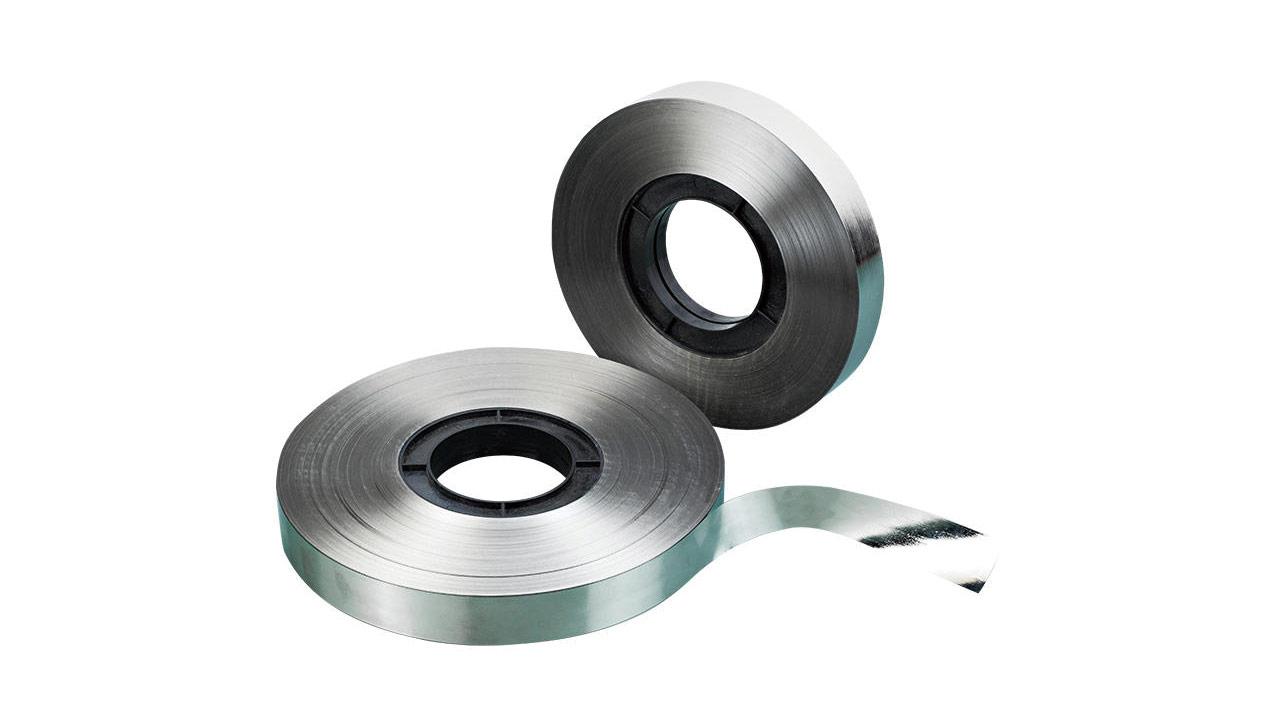

Innovations in material science are shaping the next wave of growth in the Soft Magnetic Material Market, with a focus on amorphous and nanocrystalline alloys. These advanced materials have revolutionized the industry by offering ultra-low core losses, high permeability, and excellent thermal stability—making them ideal for modern, high-efficiency magnetic applications. From high-speed transformers and inductors to next-generation electric vehicles and power electronics, these alloys are redefining magnetic component design.

Understanding Amorphous and Nanocrystalline Alloys

Unlike traditional silicon steels, amorphous alloys have a non-crystalline, disordered atomic structure. This unique configuration significantly reduces eddy current and hysteresis losses, resulting in superior magnetic performance. Amorphous materials exhibit low coercivity and high saturation magnetization, making them ideal for high-frequency transformer cores and energy-saving devices.

Nanocrystalline materials, on the other hand, are composed of ultra-fine grains—typically 10–20 nanometers—offering a balance between high magnetic permeability and saturation flux density. These alloys provide better performance under AC magnetic fields, enabling compact core designs without sacrificing efficiency or power output.

Together, these materials are unlocking new possibilities in magnetic component design by reducing energy loss, minimizing heat generation, and allowing downsizing of devices.

Applications in Power Electronics and Energy Systems

The high-frequency characteristics of amorphous and nanocrystalline alloys make them particularly suitable for power electronics. Inverters, converters, and transformers operating at elevated frequencies benefit significantly from these materials, which reduce the size and weight of magnetic components while improving thermal behavior.

In renewable energy systems, such as solar inverters and wind turbine converters, these materials support fast-switching operations, thereby improving overall power conversion efficiency. In electric vehicles, they are used in onboard chargers and DC-DC converters, enabling lighter, more compact modules with lower energy consumption.

Additionally, nanocrystalline cores are increasingly used in common mode chokes and electromagnetic interference (EMI) filters to manage noise and harmonics in sensitive power circuits, particularly in data centers, medical devices, and telecom infrastructure.

Industry R&D Focus and Global Collaboration

Global research institutions and corporations are investing in the development of customized amorphous and nanocrystalline alloys tailored for specific applications. These include efforts to enhance corrosion resistance, improve manufacturability, and achieve consistent performance across temperature ranges.

Collaborative research between universities, national labs, and industry leaders is generating rapid advances in rapid solidification techniques and magnetic property tuning. Technologies such as melt spinning, controlled annealing, and advanced coil winding are being refined to maximize material performance and enable mass production at scale.

China, Japan, and Germany are leading in academic-industrial research programs aimed at optimizing alloy compositions, while companies in the U.S. and South Korea are advancing manufacturing processes to lower production costs.

Manufacturing Advancements and Challenges

Despite their advantages, the production of amorphous and nanocrystalline materials is technically demanding. These materials require precise control during the cooling and annealing processes, and equipment must be capable of handling delicate ribbon or strip forms.

Manufacturers are overcoming these challenges by automating fabrication processes and introducing protective coatings that reduce brittleness and enhance durability. New lamination techniques and modular core designs are allowing better handling during device assembly and improving long-term stability.

Cost remains a barrier for widespread adoption, especially in price-sensitive markets. However, with economies of scale and technological refinement, the cost-performance gap is narrowing. As demand increases, especially in EVs and grid systems, production volumes are expected to rise, making these materials more economically viable.

Environmental and Efficiency Gains

The use of amorphous and nanocrystalline materials aligns with global efforts to enhance energy efficiency and sustainability. Compared to traditional materials, these alloys can reduce no-load losses in transformers by up to 75%, translating into substantial energy savings over time. This makes them attractive to utilities and governments aiming to cut electricity wastage and reduce carbon emissions.

Their compatibility with eco-friendly manufacturing processes—such as solvent-free coatings and recyclable packaging—further strengthens their environmental credentials. As ESG (Environmental, Social, and Governance) compliance becomes a competitive advantage, adoption of these advanced materials is poised to accelerate.

Market Dynamics and Competitive Landscape

The growing demand for high-efficiency magnetic components is intensifying competition among alloy manufacturers. Companies are focusing on proprietary formulations, patent-protected processing techniques, and integrated manufacturing lines to differentiate their offerings.

Some firms are entering into joint ventures with transformer and EV component producers to co-develop next-generation magnetic products. This vertical integration not only enhances product compatibility but also ensures secure, long-term supply relationships.

Moreover, startups and research-focused firms are entering the scene with niche innovations in material structure and core geometries, offering custom solutions for aerospace, defense, and high-frequency industrial applications.

Future Prospects: Toward Intelligent Magnetic Materials

Looking ahead, amorphous and nanocrystalline alloys are likely to evolve into even more intelligent materials, capable of adapting to variable operating conditions. Researchers are exploring self-monitoring magnetic cores equipped with embedded sensors for real-time diagnostics and performance optimization.

Additive manufacturing and nanotechnology will also play a key role in the future of these materials, enabling design flexibility and precision that were previously unattainable. As materials become smarter, lighter, and more adaptable, their application scope will expand into emerging fields like wireless power transfer, AI-powered robotics, and compact IoT energy modules.

In the next article, we’ll explore how the Soft Magnetic Material Market Attracts Investments Due to Compact Electronics and Miniaturization Trends, a crucial frontier for consumer electronics and mobile device innovation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness