Rotary Pumps Market Analysis Highlights Key Segments and Regional Growth Dynamics

Introduction: Understanding Market Segmentation and Geographic Momentum

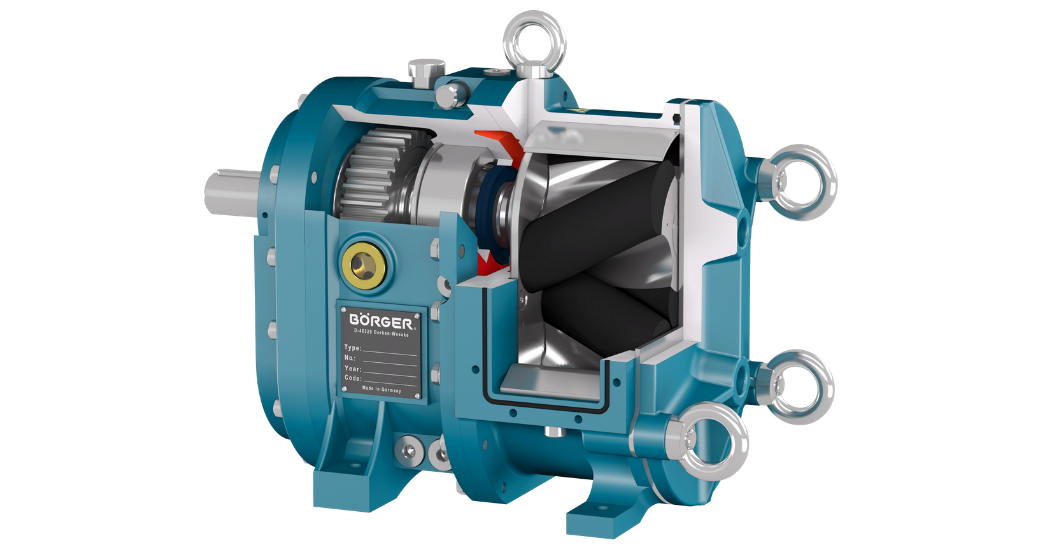

The Rotary Pumps Market continues to evolve, driven by a blend of technological innovation, end-user diversity, and regional development. A deep dive into the market reveals distinct growth patterns across segments such as pump type, end-use industries, and geographical regions. Rotary pumps—vital for fluid transfer in high-precision and heavy-duty operations—are finding tailored applications in everything from chemical plants and power generation to pharmaceuticals and wastewater management. These market segments are being shaped not only by operational needs but also by regional investments, regulatory pressures, and energy efficiency goals.

Market Segmentation by Pump Type

The rotary pumps industry is segmented into various types, each designed to address specific performance characteristics:

-

Gear Pumps: Known for their reliability in medium-pressure applications, gear pumps are heavily utilized in lubrication, chemical transfer, and hydraulic systems.

-

Screw Pumps: Offering smooth flow and low pulsation, these are common in oil and gas processing, especially for viscous or abrasive fluids.

-

Vane Pumps: Preferred in automotive and HVAC systems due to their quiet operation and precise flow control.

-

Lobe and Peristaltic Pumps: Frequently used in the food, beverage, and pharmaceutical sectors for handling delicate or shear-sensitive fluids.

Each type has seen varying levels of demand based on application requirements, with screw and gear pumps maintaining dominance in industrial and process-heavy environments.

Segmentation by End-Use Industries

Rotary pumps cater to a wide spectrum of industries, each driving unique market dynamics:

-

Oil & Gas: As a traditional stronghold, this sector maintains significant demand for rotary pumps, particularly in upstream and midstream processes.

-

Chemical Processing: Rising safety regulations and complex chemical compositions have boosted the demand for sealless and corrosion-resistant pumps.

-

Water and Wastewater Management: Increasing investment in municipal infrastructure is elevating rotary pump usage for sludge handling, dosing, and dewatering.

-

Food & Beverage: Hygienic and FDA-compliant pumps are required to handle food-grade fluids, dairy, and beverages with gentle action.

-

Pharmaceuticals: Precision and sterilization requirements make peristaltic and lobe rotary pumps crucial for liquid drug manufacturing and transfer.

These verticals contribute to market heterogeneity, ensuring that no single industry dominates, which adds to the resilience of the rotary pumps market.

Regional Growth Analysis: Global Expansion Patterns

The rotary pumps market exhibits distinct regional dynamics, shaped by infrastructure development, industrial maturity, and energy policies.

-

Asia-Pacific: This region leads in growth, driven by rapid industrialization in China, India, Indonesia, and Vietnam. Infrastructure projects, refinery expansion, and chemical production are fueling demand.

-

North America: Mature markets like the U.S. and Canada are focused on upgrading aging infrastructure and integrating energy-efficient pump systems, especially in oil, food, and wastewater sectors.

-

Europe: Sustainability regulations, such as the EU’s Green Deal, are accelerating adoption of eco-friendly and high-efficiency rotary pumps in manufacturing and utilities.

-

Middle East & Africa: Continued investment in petrochemical facilities and desalination plants is generating steady demand for high-capacity and corrosion-resistant rotary pumps.

-

Latin America: Emerging markets like Brazil and Mexico are showing modest but steady growth in industrial processing and water management.

Each region presents a unique blend of opportunities and constraints, influencing product customization and marketing strategies.

Market Share and Competitive Breakdown

Analysis of market share shows a mix of global giants and regional specialists. Leading manufacturers are gaining ground through product differentiation, integrated systems, and robust after-sales services. However, regional firms remain competitive by offering cost-effective, application-specific solutions tailored to local conditions.

Mergers, acquisitions, and joint ventures are reshaping competitive dynamics, with global players aiming to strengthen distribution networks and technology capabilities in high-growth regions. For example, partnerships between pump manufacturers and energy infrastructure firms have increased in Asia-Pacific and the Middle East to provide turnkey solutions.

Technological Penetration Varies by Segment

Technology adoption is not uniform across all segments. High-end industries like pharmaceuticals and chemicals are early adopters of smart pumping technologies, while traditional sectors like agriculture and water management are gradually integrating variable speed drives and condition monitoring systems.

Regions with strong digital infrastructure are leading in smart pump implementation, whereas others still prioritize durability and cost-effectiveness over advanced automation. This split offers pump manufacturers the ability to diversify product lines based on regional and sectoral technology readiness.

Conclusion: A Market Defined by Nuance and Regional Strategy

The Rotary Pumps Market is far from monolithic. It is shaped by nuanced segment demands and the diverse pace of regional development. Manufacturers and stakeholders that tailor their offerings to local industry needs, regulatory environments, and technological maturity are poised for sustainable growth.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness