Composite Roller Market Gains Momentum as Industries Shift Toward Energy Efficient Conveyor Solutions

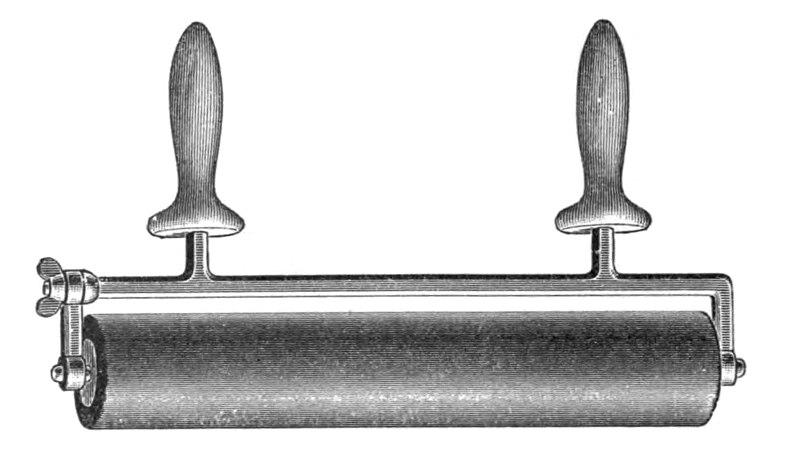

The composite roller market is undergoing a significant transformation, driven by advancements in material science, growing industrial demands, and the need for lightweight, high-performance components. Composite rollers, typically made from a combination of fiberglass, carbon fiber, and resins, are increasingly replacing traditional steel rollers in various industrial applications, including mining, paper and pulp, textile, and material handling industries. These rollers are recognized for their corrosion resistance, low rotational inertia, and superior strength-to-weight ratio.

One of the primary drivers of the composite roller market is the mining industry's shift toward more efficient and durable equipment. In mining operations, conveyor systems play a pivotal role in transporting heavy loads over long distances, often in harsh environmental conditions. Composite rollers provide a significant advantage in such conditions due to their resistance to moisture, chemicals, and temperature fluctuations. Moreover, their lightweight nature reduces the overall energy consumption of conveyor systems, contributing to operational cost savings and improved sustainability.

Additionally, the paper and pulp industry is witnessing an increased adoption of composite rollers. The non-corrosive and smooth surface of these rollers ensures better paper quality and reduces maintenance requirements. In highly sensitive manufacturing environments, such as cleanrooms in semiconductor or pharmaceutical production, the low-particulate generation of composite rollers becomes a critical feature, ensuring contamination-free operations.

Another trend bolstering the market is the global push for energy efficiency and reduced carbon emissions. As industries aim to lower their environmental impact, the use of lightweight composite materials helps reduce energy consumption in material handling systems. With governments and regulatory bodies worldwide enforcing stricter emission standards, industries are under pressure to upgrade to more sustainable solutions—giving composite rollers a competitive edge.

Geographically, the Asia-Pacific region dominates the composite roller market, led by rapid industrialization in countries like China, India, and Southeast Asia. Infrastructure development, expansion of mining operations, and increasing demand for manufacturing automation are some of the factors propelling the regional market. North America and Europe are also strong markets, supported by technological innovation, stringent environmental norms, and a high focus on operational efficiency.

The market, however, is not without challenges. The initial cost of composite rollers is higher compared to traditional metal rollers, which may deter small- to medium-scale industries from making the switch. Additionally, the need for skilled labor and technical expertise for proper installation and maintenance of composite systems can be a limiting factor in some regions. Despite these hurdles, the long-term benefits in terms of durability, reduced downtime, and energy efficiency often outweigh the upfront costs, making composite rollers a viable long-term investment.

From a competitive standpoint, the market is characterized by the presence of both established global players and emerging regional manufacturers. Key players are focusing on research and development to enhance product performance, develop specialized rollers for niche applications, and create cost-effective solutions to expand their customer base. Mergers, acquisitions, and strategic partnerships are also common as companies seek to strengthen their market position and tap into new regional markets.

Technological advancements are another pivotal factor shaping the composite roller market. Innovations in polymer resins and fiber reinforcements are enabling manufacturers to produce rollers with higher load-bearing capacities, extended service life, and tailored properties to suit specific applications. Furthermore, the integration of sensors and IoT (Internet of Things) technology into composite rollers is an emerging trend. These smart rollers can monitor wear, temperature, and vibration in real-time, facilitating predictive maintenance and minimizing unplanned downtime.

Looking ahead, the composite roller market is expected to continue its growth trajectory, fueled by industrial automation, environmental sustainability goals, and the growing demand for high-performance materials. As industries worldwide strive for more reliable, efficient, and eco-friendly solutions, composite rollers are well-positioned to become the standard in various sectors. Continued investment in R&D, cost optimization, and awareness campaigns will be critical to overcoming adoption barriers and unlocking the full potential of this promising market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness