What Should You Know About Choosing Grinding Wheels for Metal?

Grinding wheels for metal are essential tools in various industrial and fabrication settings. Whether for surface preparation, shaping, or removing excess material, these abrasive tools provide reliable performance across different types of metal. Choosing the right grinding wheels for metal depends on several factors, including the material type, grinding technique, and desired finish.

Grinding wheels for metal are made using abrasive grains bonded together with a durable material such as resin or ceramic. The type of abrasive grain used—such as aluminum oxide, zirconia alumina, or silicon carbide—can significantly influence how effectively the wheel works with specific metals. For example, aluminum oxide is often suitable for grinding steel, while silicon carbide is more appropriate for softer metals like aluminum or copper.

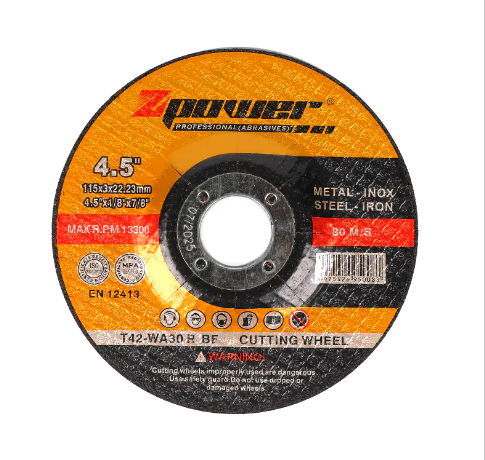

In metal fabrication shops, grinding wheels for metal are used in operations ranging from deburring welded joints to smoothing sharp edges. These wheels come in various shapes and sizes, such as flat discs, cup wheels, and depressed center wheels, depending on the specific task. For cutting through thick materials, wheels with a harder bond and coarser grit may be required. Meanwhile, finer grit wheels are better for finishing work that requires more precision and a smoother surface.

Another important consideration when selecting grinding wheels for metal is the speed rating. Each wheel is designed to operate at a specific rotational speed. Using a wheel beyond its rated speed can result in premature wear or even safety hazards. It is critical to match the wheel to the machine's specifications to ensure both performance and operator safety.

Storage and handling of grinding wheels for metal should also not be overlooked. Wheels should be stored in a dry, vibration-free area to prevent cracking or warping. Before use, it's good practice to inspect the wheel for any visible damage. Damaged wheels can break during operation, posing risks to both the operator and the equipment.

In industries such as automotive repair, construction, and metalworking, grinding wheels for metal play a consistent role in day-to-day operations. Their durability and efficiency make them a practical choice for users who need reliable abrasives for different applications. Regular maintenance of both the wheel and the grinding machine ensures better performance over time.

Grinding wheels for metal are versatile tools used in cutting, shaping, and surface finishing. Selecting the right type based on grit, bonding material, and abrasive grain ensures effective results. By understanding the proper usage, storage, and application of these tools, professionals can maintain high work standards without compromising safety or efficiency.

https://www.cuttingdiscfactory.com/product/resin-grinding-discs/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness