What Should You Consider When Choosing an Angle Iron Processing Machine?

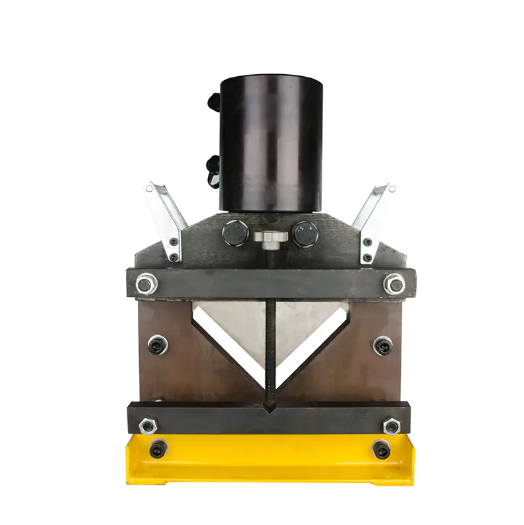

An Angle Iron Processing Machine is an essential tool in metalworking and fabrication industries. This specialized equipment is designed to handle angle irons—metal sections shaped with an L-profile that are commonly used in construction, manufacturing, and structural applications. The machine’s ability to process these materials efficiently plays a critical role in ensuring precision and productivity in various projects.

The primary role of an Angle Iron Processing Machine is to cut, shape, drill, or punch angle irons according to specific requirements. These tasks often demand accuracy and repeatability, as angle irons are frequently used in frameworks, support structures, and machinery parts. The machine helps reduce manual labor and potential errors, allowing for more consistent and reliable results.

Different types of Angle Iron Processing Machines are available depending on the operations needed. Some machines focus on cutting angle irons to length with clean and straight cuts, while others may offer additional functions such as hole punching or bending. Multi-functional machines combine several processing steps, which can save time and space in a workshop environment.

One important feature of an Angle Iron Processing Machine is its ability to handle various sizes and thicknesses of angle iron. This flexibility makes the machine suitable for diverse projects, ranging from small-scale fabrication to heavy-duty construction tasks. Adjustable settings allow operators to customize the machine’s performance to match the material specifications and design goals.

Safety is a key consideration in the design of an Angle Iron Processing Machine. Many machines include protective covers, emergency stop buttons, and sensors to prevent accidents during operation. Proper training and adherence to safety guidelines also contribute to a secure working environment when using such equipment.

The efficiency of an Angle Iron Processing Machine directly affects project timelines. Automated or semi-automated machines reduce processing times compared to manual methods, allowing fabricators to complete orders faster and with greater precision. This aspect can lead to cost savings and improved workflow in busy production settings.

Maintenance and durability are also critical for an Angle Iron Processing Machine. Regular maintenance helps keep the machine in good working order, ensuring that cuts and punches remain accurate over time. Quality components and sturdy construction extend the machine’s service life, providing reliable performance across many projects.

For businesses involved in structural steel fabrication, investing in an Angle Iron Processing Machine can improve overall operational capacity. By reducing manual effort and increasing the speed of processing, the machine supports consistent product quality and efficient resource use.

The Angle Iron Processing Machine is a valuable asset in metal fabrication industries. Its ability to handle multiple processing tasks with accuracy and safety helps manufacturers meet production demands and maintain quality standards. Considering factors such as versatility, safety features, and maintenance needs can guide users in selecting the appropriate machine for their specific angle iron processing requirements.

https://www.cncabletools.com/product/angle-iron-processing-machine/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness