Low Voltage Cable Market Pain Points Hindering Growth and Efficiency Worldwide

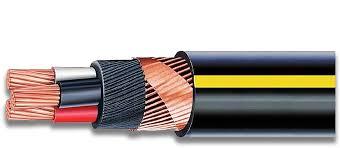

The low voltage cable market, essential to power distribution in residential, commercial, and industrial sectors, faces several critical pain points that hamper its growth, efficiency, and competitiveness. These cables, typically rated up to 1,000 volts, are foundational to modern infrastructure, yet their production, distribution, and application involve complex challenges. From fluctuating raw material prices to inconsistent regulatory frameworks and technological disruptions, the pain points in this sector demand urgent attention from stakeholders to ensure sustainability and long-term success.

Volatile Raw Material Prices

One of the most pressing pain points in the low voltage cable market is the high volatility in raw material prices, particularly copper and aluminum. These metals are essential for cable conductors, and any fluctuation directly impacts manufacturing costs. The global commodities market often experiences unpredictable shifts due to geopolitical tensions, economic instability, and supply-demand imbalances.

Manufacturers struggle to maintain price consistency and profitability in the face of such fluctuations. Long-term contracts become challenging to negotiate, and frequent price revisions can strain relationships with buyers, especially in public infrastructure and construction projects with fixed budgets.

Complex Regulatory Compliance

The cable industry must adhere to a variety of international, national, and regional standards, which often vary significantly. This regulatory fragmentation creates compliance hurdles, especially for manufacturers operating across multiple markets. Different safety, fire resistance, and environmental standards require custom product designs, increasing both production time and cost.

Moreover, many countries are updating their building codes and energy efficiency regulations to align with sustainability goals. While these are positive changes, keeping up with regulatory evolution poses a logistical and financial burden, particularly for small and mid-sized enterprises (SMEs).

Counterfeit and Substandard Products

The prevalence of counterfeit or low-quality cables in developing markets is a persistent issue that compromises safety and market credibility. Substandard products not only pose fire and electrocution risks but also undermine the reputation of certified manufacturers who invest heavily in quality assurance.

These counterfeit cables are often sold at lower prices, creating unfair competition. Without strict enforcement of quality standards and efficient certification mechanisms, trusted manufacturers face reduced market share and consumer trust issues. This pain point is especially severe in markets where regulation enforcement is weak or inconsistent.

Supply Chain Inefficiencies

Global supply chains for low voltage cable components are highly interconnected and vulnerable to disruptions. Events such as pandemics, natural disasters, port congestion, and geopolitical conflicts can delay the delivery of raw materials and finished goods alike.

Such delays lead to project slowdowns and increased warehousing costs. Manufacturers are also forced to maintain higher inventory levels to hedge against uncertainties, tying up working capital. These inefficiencies ultimately affect the end-user in the form of higher prices and delayed installations.

Technological Gaps and Digital Lag

Despite the growing need for intelligent power distribution and Industry 4.0 integration, the low voltage cable market still faces technological gaps and digitalization challenges. Many cable manufacturers, especially in developing economies, have not fully embraced automation, data analytics, or smart manufacturing systems.

This lag prevents them from optimizing production, improving quality control, and achieving cost efficiencies. Additionally, the lack of real-time monitoring and tracking systems makes it harder to offer value-added services such as predictive maintenance or lifecycle tracking—features that are increasingly demanded in high-tech applications like data centers and electric vehicle infrastructure.

Skilled Labor Shortage

As with many manufacturing industries, the low voltage cable sector suffers from a shortage of skilled labor, particularly in areas requiring technical expertise such as cable design, installation, and testing. An aging workforce and insufficient vocational training programs further widen this gap.

Without skilled technicians, the risk of improper installation and maintenance increases, leading to system failures and safety hazards. Companies must invest in workforce development and training to ensure they can meet rising quality and safety expectations across projects of all scales.

Limited Product Differentiation

In an increasingly competitive market, many cable manufacturers struggle with limited product differentiation. The commoditized nature of low voltage cables makes it difficult to compete beyond pricing, leading to margin pressures.

While innovation in materials and performance is underway, only a few companies have the resources to invest significantly in research and development. Smaller players face the challenge of staying relevant without compromising on quality or cost, making the path to growth more complicated.

Environmental and Sustainability Pressures

With rising awareness of environmental issues, manufacturers face pressure to adopt greener practices and materials. However, transitioning to sustainable production often requires significant upfront investment in new machinery, eco-friendly materials, and waste management systems.

For many players, especially in emerging markets, balancing cost-efficiency with environmental responsibility remains a major pain point. Compliance with global ESG (Environmental, Social, and Governance) standards is becoming a necessity, but the lack of financial and technical support hinders widespread adoption.

Conclusion

The low voltage cable market plays a crucial role in powering modern life, yet it is weighed down by multiple pain points that obstruct growth and innovation. From material cost instability and regulatory complexity to technological lags and environmental compliance burdens, these challenges must be proactively addressed. A collaborative approach involving governments, industry associations, and private players is essential to streamline regulations, enhance quality control, support digital transformation, and promote sustainable practices. Tackling these pain points head-on will not only improve operational efficiency but also position the industry for long-term success in a rapidly changing global energy and infrastructure landscape.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness