The Practical Advantages of Using a Ribbon Cutting Machine in Production

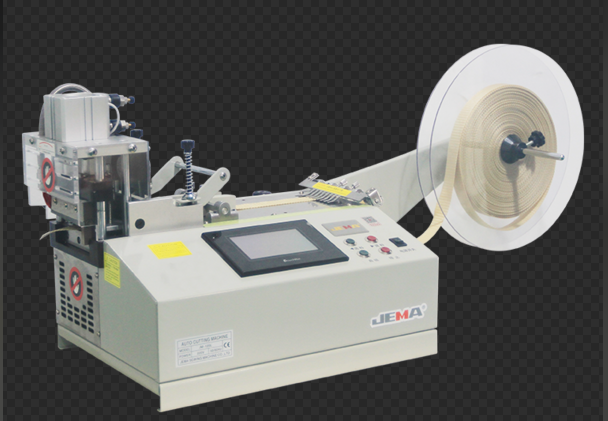

In many industries, precision and efficiency are crucial when working with ribbon or narrow fabric materials. A ribbon cutting machine offers a range of practical benefits that support streamlined workflows and material accuracy. Designed to process a variety of ribbon types including satin, nylon, and polyester, this machine helps users achieve consistent cutting results.

One notable advantage of using a ribbon cutting machine is its ability to reduce manual labor. Traditional methods of cutting ribbons often involve hand tools or basic equipment, which may lead to uneven edges or slower production speed. In contrast, a ribbon cutting machine automates the process, delivering repeatable and clean cuts with adjustable settings for length and speed.

Another benefit lies in the machine’s cutting versatility. Some machines support both cold and hot cutting modes, allowing users to select the method that suits their material type. Hot cutting also helps seal the ribbon edges to prevent fraying, which is particularly useful for packaging or textile applications.

The compact structure of most ribbon cutting machines also makes them suitable for limited workspace environments. Whether used in small studios or large-scale production sites, this equipment can easily integrate into various workflows.

In summary, the ribbon cutting machine is a valuable tool for businesses looking to improve operational consistency while saving time and minimizing material waste.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness