Printed Sensors Market Pain Points Slowing Widespread Commercial Adoption and Scale

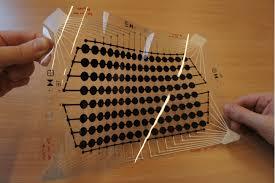

The printed sensors market, while experiencing significant innovation and application growth, is also grappling with a number of critical pain points that challenge its large-scale adoption. Printed sensors, manufactured using advanced printing techniques like inkjet and screen printing on flexible substrates, offer compelling benefits such as cost-effectiveness, lightweight design, and adaptability for diverse use cases. However, these advantages are often offset by technological limitations, supply chain inconsistencies, regulatory uncertainty, and issues related to performance, integration, and standardization. Understanding these pain points is essential for stakeholders aiming to navigate this evolving landscape and achieve scalable growth.

Performance and Accuracy Limitations

A major pain point in the printed sensors market is the relatively lower sensitivity and accuracy compared to conventional silicon-based sensors. While printed sensors are ideal for applications that demand flexibility and affordability, they often struggle to meet the high precision requirements needed in sectors such as aerospace, industrial automation, and advanced healthcare diagnostics. Inconsistent signal output, limited resolution, and environmental susceptibility remain persistent issues, leading end-users to hesitate when considering printed alternatives for mission-critical applications.

Material Compatibility and Ink Limitations

Another significant challenge lies in the limited availability of functional inks and compatible substrates. The performance of printed sensors is heavily influenced by the properties of conductive, semiconductive, and dielectric inks used in their fabrication. These inks must maintain stability under mechanical stress, heat, humidity, and UV exposure. However, many commercially available inks face degradation over time or under variable environmental conditions, which reduces the lifespan and reliability of the sensors. Additionally, not all substrates work seamlessly with all ink types, making material selection a complex and costly task.

Manufacturing Scale-Up Constraints

While printed sensor technology is suitable for low-volume, custom, and prototyping applications, scaling up for high-volume production presents significant hurdles. The uniformity and repeatability of sensor quality in mass production are often difficult to achieve due to variations in printing precision and environmental conditions during manufacturing. Many printing techniques require controlled environments to maintain quality, adding to production costs. Furthermore, the lack of established production standards means manufacturers must develop proprietary solutions, which increases time-to-market and limits economies of scale.

Integration and Compatibility Challenges

Printed sensors often face difficulties when integrated into existing electronic systems and product architectures. Compatibility with power supplies, signal processing units, wireless modules, and data interfaces is not always straightforward, especially when printed components differ in form factor and electrical characteristics. Moreover, printed sensors may require unique calibration protocols or additional components for signal amplification, which complicates the design and increases costs for OEMs (Original Equipment Manufacturers). This creates friction in achieving plug-and-play functionality, a key requirement in today's fast-paced electronics industry.

Standardization and Certification Gaps

One of the most overlooked yet critical pain points is the absence of universal industry standards and testing benchmarks for printed sensors. Without clear guidelines, manufacturers struggle to validate product quality, ensure interoperability, and gain regulatory approvals for use in safety-critical or medical environments. This lack of standardization slows down commercialization and deters investors and adopters who seek performance assurances. Certification agencies also face difficulties in classifying printed sensors within existing regulatory frameworks, leading to prolonged approval timelines and uncertain market entry pathways.

High R&D Costs and Long Development Cycles

Despite being touted as cost-effective alternatives, printed sensors often require substantial R&D investment before reaching market readiness. Innovations in materials, ink formulations, and printing technologies demand continuous experimentation and testing. Development cycles can be lengthy, especially when custom solutions are needed for niche applications. For startups and smaller enterprises, this acts as a barrier to entry and limits the pace of innovation. Even for established players, the need for constant innovation to remain competitive adds to operational pressure.

Environmental Durability and Reliability Issues

Printed sensors are particularly vulnerable to environmental factors such as moisture, temperature fluctuations, and physical abrasion. In applications where sensors are exposed to outdoor or industrial environments, durability becomes a major concern. Protective coatings and encapsulation can address these issues, but they add layers of complexity, weight, and cost to the sensor design. Until printed sensors can offer long-term stability and ruggedness comparable to traditional sensors, their application scope will remain limited.

Limited End-User Awareness and Education

The final pain point relates to market perception and user education. Many potential adopters are still unaware of the capabilities and limitations of printed sensors. This lack of understanding often leads to mismatched expectations, improper use, or underestimation of integration requirements. Additionally, decision-makers in industries such as healthcare, automotive, and infrastructure tend to prefer mature, proven technologies over emerging ones, making it harder for printed sensors to break into legacy systems.

Conclusion

The printed sensors market holds immense potential, but its path to widespread adoption is hindered by a range of technical, operational, and market-related pain points. From performance and material limitations to standardization gaps and integration challenges, these issues need to be addressed through sustained research, collaboration, and education. For manufacturers and innovators, overcoming these barriers will require a strategic focus on quality, interoperability, and end-user needs. As solutions emerge to tackle these pain points, the printed sensors market will be better positioned to fulfill its promise in the future of sensing technologies.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness