CNC Machining Services: High-Precision Manufacturing Solutions

In modern manufacturing, CNC machining services have become essential for producing accurate and complex parts across various industries. This technology uses computer-controlled machines to shape materials into precise components, making it ideal for both prototyping and mass production.

Understanding CNC Machining Services

CNC (Computer Numerical Control) machining is a manufacturing process where pre-programmed software directs the movement of factory tools and machinery. The process can create parts from metals, plastics, and composites with high accuracy and repeatability.

Key Benefits of CNC Machining

CNC machining offers several advantages that make it preferable for industrial applications:

-

Exceptional Precision: Capable of achieving tolerances within ±0.005 mm

-

Material Versatility: Works with aluminum, steel, titanium, plastics, and more

-

High Repeatability: Produces identical parts in large quantities

-

Fast Production: Reduces lead times compared to manual machining

Common CNC Machining Processes

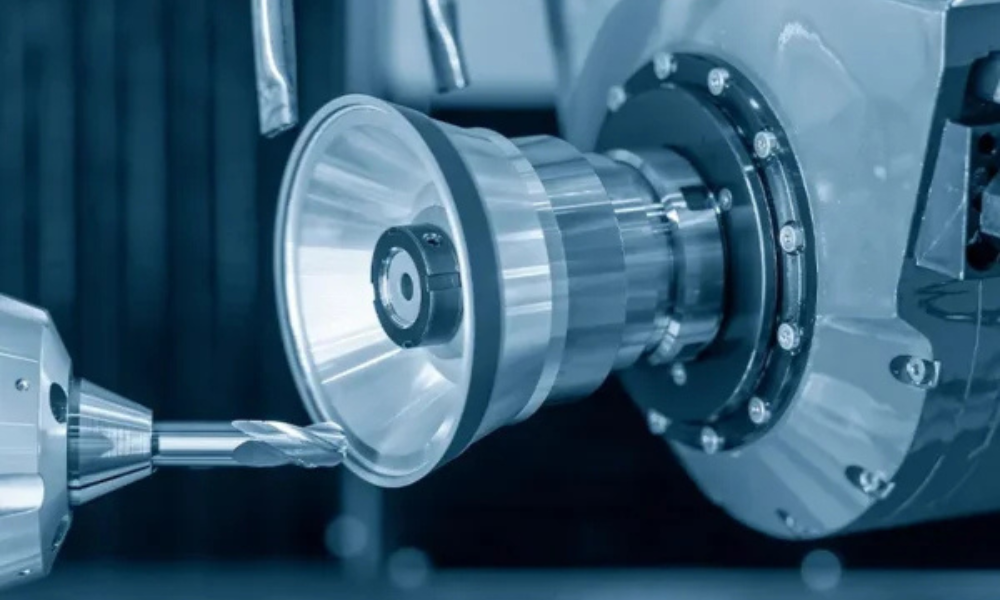

CNC Milling

CNC milling uses rotating cutting tools to remove material from a workpiece. It is suitable for creating complex geometries, slots, and pockets. Industries such as automotive and aerospace frequently use milling for engine components and structural parts.

CNC Turning

In CNC turning, the workpiece rotates while a stationary cutting tool shapes it. This method is ideal for cylindrical parts like shafts, bushings, and connectors. It is widely used in hydraulic systems and industrial machinery.

Multi-Axis Machining

Advanced CNC machines with 3-axis, 4-axis, or 5-axis capabilities can produce intricate parts in a single setup. This technology is valuable for aerospace components, medical implants, and complex automotive parts.

Industries Using CNC Machining Services

Aerospace and Defense

The aerospace sector relies on CNC machining for turbine blades, landing gear components, and structural fittings. These parts require strict adherence to specifications and high-performance materials like titanium and aluminum alloys.

Medical and Dental

CNC machining produces surgical instruments, implants, and prosthetics with biocompatible materials. The medical industry demands sterile, high-precision components that meet regulatory standards.

Automotive Manufacturing

From engine blocks to transmission parts, CNC machining ensures durability and precision in automotive components. The technology supports both prototyping and full-scale production.

Electronics and Consumer Goods

CNC machining creates heat sinks, enclosures, and connectors for electronic devices. The process delivers smooth finishes and tight tolerances required for functional parts.

Selecting a CNC Machining Provider

When choosing a CNC machining service, consider the following factors:

-

Machining Capabilities: Ensure the provider has the necessary equipment for your project

-

Material Options: Verify availability of metals, plastics, or specialty alloys

-

Quality Standards: Look for ISO 9001 or AS9100 certifications

-

Production Capacity: Check if they support prototyping and large-scale orders

Future Developments in CNC Machining

The future of CNC machining includes greater automation, AI-driven optimization, and hybrid manufacturing techniques. These advancements will further improve precision, reduce waste, and shorten production times.

Conclusion

CNC machining services provide a reliable solution for high-precision manufacturing. Whether for prototyping or mass production, this technology delivers consistent quality across various industries.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness