Cap Liner Market Growth Challenges and Strategic Approaches to Overcome Industry Fragmentation and Compliance

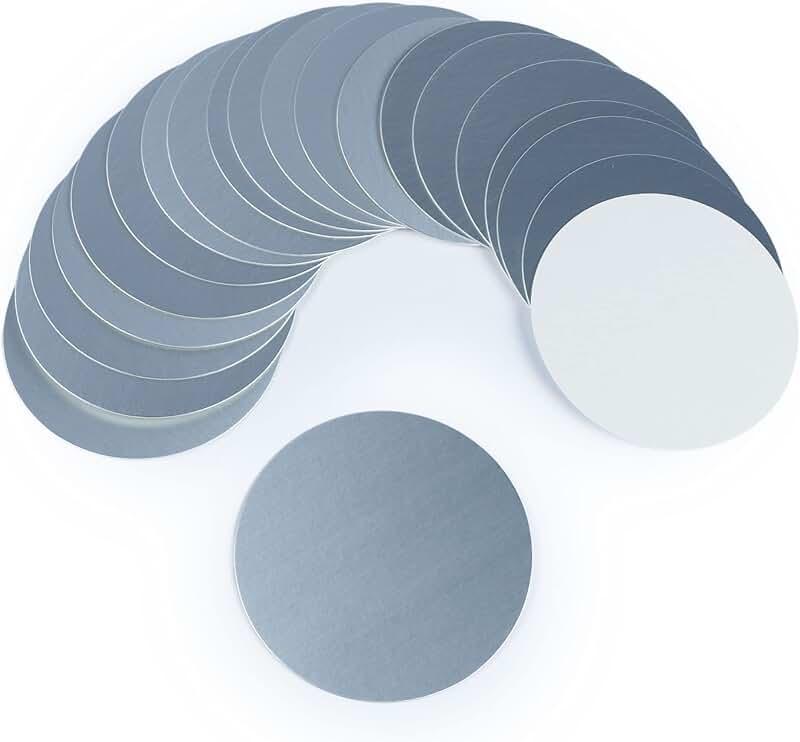

The cap liner market plays a vital role in the packaging industry, ensuring the integrity, safety, and freshness of bottled and canned products. Cap liners, often made from materials such as foam, pulp, or plastic, act as seals inside bottle caps to prevent leakage, contamination, and spoilage. Despite the growing demand driven by expanding food and beverage, pharmaceutical, and cosmetics industries, the cap liner market faces several significant challenges that could potentially slow its growth trajectory.

One of the primary growth challenges in the cap liner market is the increasing pressure to adopt environmentally friendly and sustainable materials. Traditional cap liners have predominantly relied on plastic-based materials like polyethylene and foam, which contribute to environmental pollution and are difficult to recycle. With governments worldwide imposing stringent regulations on plastic usage and consumers becoming more eco-conscious, manufacturers are compelled to innovate biodegradable and recyclable alternatives. However, these sustainable materials often come with higher production costs and may not yet match the performance and durability of conventional liners. Balancing sustainability with functionality remains a tough hurdle for the industry.

Raw material price volatility is another major obstacle impacting the cap liner market. The prices of polymers and other base materials fluctuate due to supply chain disruptions, geopolitical tensions, and changes in crude oil prices. Such instability increases production costs unpredictably, forcing manufacturers to either absorb the costs or pass them on to customers. Both scenarios can adversely affect profit margins and market demand, especially in price-sensitive sectors like food and beverage. Moreover, the reliance on petrochemical-derived materials adds uncertainty to long-term supply and pricing, challenging manufacturers to diversify their raw material sources.

Technological innovation, while essential, also presents a challenge for the cap liner market. The demand for liners that offer better sealing, chemical resistance, and compatibility with different container types pushes manufacturers to invest heavily in research and development. Small and mid-sized players often struggle with the financial and technical resources required to innovate and keep up with evolving industry standards. Additionally, new liner designs and materials must undergo rigorous testing and certification, which can delay product launches and increase time-to-market. This slows down the adoption of improved liners and can limit market expansion.

The market’s fragmented nature also hinders growth. Numerous manufacturers, ranging from large corporations to regional suppliers, compete in the cap liner space. This fragmentation results in inconsistent product quality and varying adherence to standards, creating challenges for global brand owners who require reliable, uniform sealing solutions across their supply chains. Furthermore, the presence of low-cost, low-quality liners in emerging markets undermines the reputation of the segment and complicates efforts by premium players to establish dominance.

Another challenge lies in the complex supply chain dynamics of the cap liner market. Cap liners are often customized for specific industries and packaging requirements, demanding close coordination between liner manufacturers, cap producers, and end-users. Any disruption in one segment—whether due to raw material shortages, transportation delays, or regulatory changes—can have a ripple effect throughout the supply chain. The COVID-19 pandemic, for example, exposed vulnerabilities in global logistics, leading to production halts and delayed deliveries. Maintaining supply chain resilience and agility is critical but remains a constant challenge for market participants.

Regulatory compliance is increasingly stringent and varies across regions, posing further challenges. Cap liners used in pharmaceutical and food packaging must meet rigorous health and safety standards to ensure no contamination occurs. Navigating the maze of regional and international regulations requires substantial investment in testing and certification. Additionally, evolving standards—such as restrictions on certain chemical additives or mandates for recyclable materials—require manufacturers to continually adapt their processes. Non-compliance risks product recalls, legal penalties, and reputational damage, which can severely impact market growth.

Consumer behavior also influences the cap liner market growth. The surge in demand for convenience packaging and single-serve products means manufacturers must design liners that maintain product freshness for shorter periods but allow for easy opening and resealing. Simultaneously, the rise of e-commerce has increased the need for secure and tamper-evident packaging. Meeting these diverse and sometimes conflicting consumer expectations demands innovation and flexibility but complicates the manufacturing process.

Despite these challenges, the cap liner market holds significant growth potential. The increasing global consumption of packaged food, beverages, and pharmaceuticals creates a steady demand for reliable sealing solutions. Manufacturers are actively investing in new materials such as biodegradable foams, plant-based liners, and improved pulp formulations to address sustainability concerns. Advancements in manufacturing technologies, including automation and precision cutting, help reduce production costs and improve liner consistency.

Moreover, collaborations between liner manufacturers, packaging companies, and regulatory bodies can help streamline compliance and innovation efforts. By focusing on customization and value-added features like antimicrobial liners or multi-layer barriers, companies can differentiate themselves and capture niche markets. Developing markets in Asia-Pacific and Latin America offer fresh growth opportunities due to rising disposable incomes and increasing packaged product consumption.

In conclusion, while the cap liner market faces multiple growth challenges—including sustainability pressures, raw material volatility, technological demands, fragmented competition, complex supply chains, regulatory compliance, and changing consumer preferences—these obstacles also drive innovation and transformation within the industry. Manufacturers that can strategically navigate these challenges by adopting sustainable materials, investing in R&D, enhancing supply chain resilience, and aligning with regulatory frameworks are well-positioned to capitalize on the expanding demand for cap liners worldwide.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness