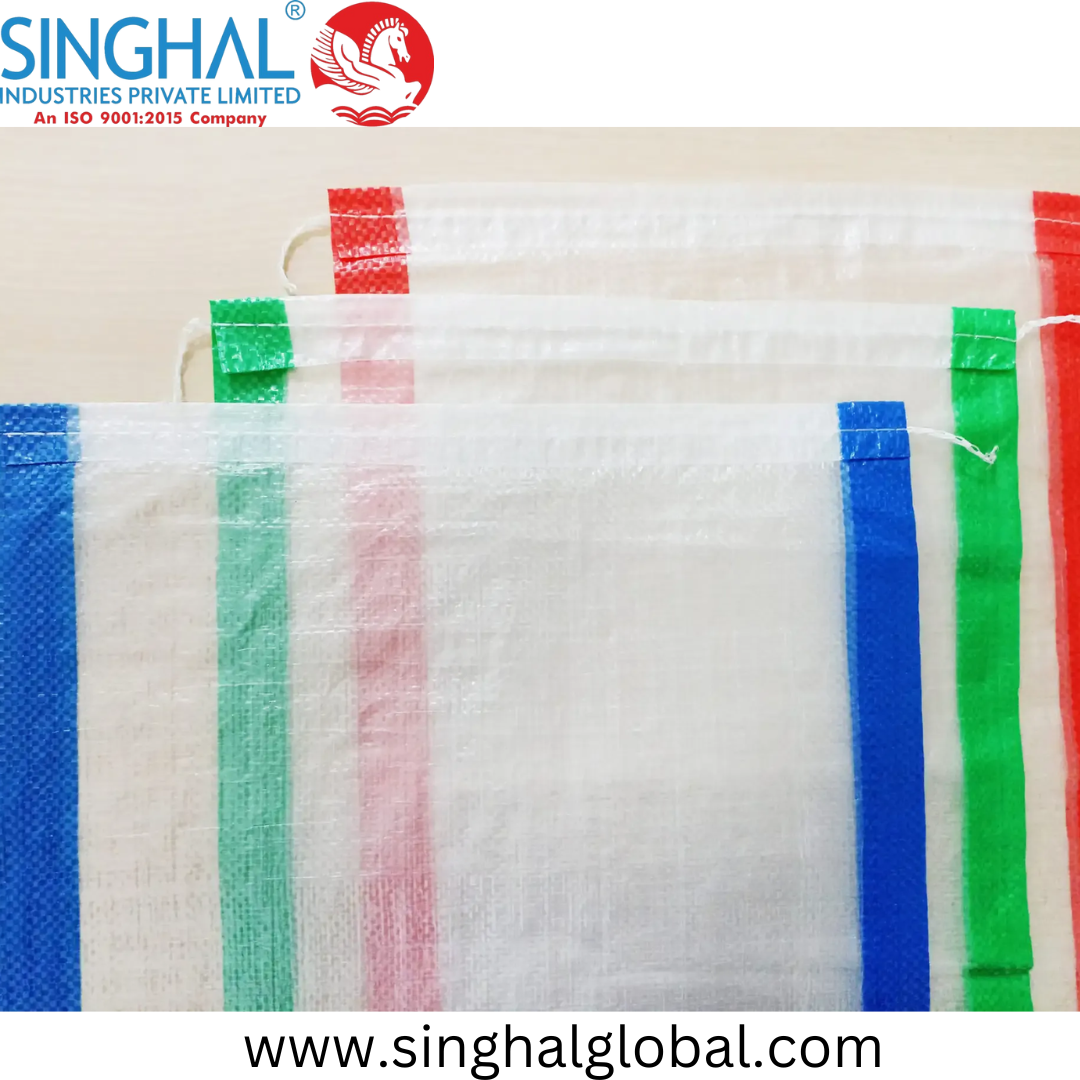

PP Woven Bags: Strong, Sustainable, and Versatile Solutions

At a time, both strong industrial requirements and defined by increasing environmental awareness are a willingness to practical innovation. More than a simple container, these bags represent a sophisticated engineering solution, born of versatile polypropylene. Their ubiquitous presence in different fields from agriculture to construction talks about their inherent strength, wonderful stability properties and remarkable adaptability. Traveling these bags, from raw resin to a reliable packaging solution, is an attractive exploration of the real world needs to the material science meeting.

The Genesis of Strength: Polypropylene’s Power

Each PP is a thermoplastic polymer obtained from polypropylene, PP FIBC bags monomers in the heart of woven bag. Magic is during the weaving process. The thin band of the polypropylene film is thrown out and then woven together in two directions, the manufacture of a cloth that is incredibly resistant to tear resistant and claims high tensile strength. It is a criscross-sampling structure that provides the bag to their extraordinary load-bearing capacity, making them ideal for granular materials, powder and even irregular goods. Unlike traditional paper or fabric bags, PP woven bags against puncture and friction, which provide better protection to the contents during transport and storage.

Beyond Durability: A Sustainable Edge

While often ignored, the PP stability profile is surprisingly strong. First, polypropylene is a recycled material in itself. Consumer PP woven bags can be collected, organized and can be converted into new plastic products, reducing the demand for virgin resources. Many manufacturers also include recycled materials in their new bags, and closes the loop further. Second, long life and recreation of these bags contribute significantly to environmental benefits. Unlike disposable packaging, a well-maintained PP knit bag can be used several times, reducing general waste production. In addition, their mild nature reduces transport costs during shipping and reduces carbon emissions.

Versatility Personified: Applications Across Industries

The pure versatility of the PP woven bag is probably their most defined characteristic. Their applications are endless from large areas where crops are collected at rebels. For example, PP bags for rice are an indispensable part of the agricultural supply chain, ensuring that this main meal reaches consumers worldwide. Their breathability, which is often improved with microscopic teaching, prevents moisture from formation and aggravated, important for grain. Similarly, wholesale objects such as sand, cement or animal feed, strong character of these bags. Their ability to be laminated or coated provides moisture, further protection against UV rays, or even acts as a barrier to fine powder, and further their utility.

Specialized Solutions: PP FIBC

The PP tissues represent a jump into the family, the PP FIBC bag, or a special section of flexible intermediate wholesale containers, bulk packaging solutions. It is designed to keep the "large bag" mostly, usually from 500 kg to 2000 kg, and is usually used to transport chemicals, minerals, fertilizers and foods. Their design includes strong lifting loops, so they can easily be handled by forklifts or cranes, significantly streamlined logistics. FIBCs can be designed with different types of filling and printed options, such as spouts or skirts to fit specific product requirements and handling processes.

Crafting Quality: The Role of the Manufacturer

The quality and reliability of the PP woven bag depends on the manufacturer's expertise. For example, a recognized PP bag manufacturer in Rajkot will use the state -Art -Art -fittings, use polypropylene resin with a high degree and follow strict quality control measures during the production process. This carefully approach ensures the strength of the bag, the exact dimension and reliable performance. Such manufacturers often offer customization options, including catering for unique needs in different industries and products, including specific sizes, printing, demolition and special coatings. The commitment to the innovation and quality of these manufacturers.

Beyond the Horizon: Future Innovations

The development of PP woven bags is over. Ongoing research and development focuses on increasing environmental information, detecting biobased polypropylene options and further improving recycling. Innovations in smart packaging, such as integrated RFID tags for trekking and inventory management are also on the horizon. Easily continues the demand for incredibly strong content, promises even more efficient and durable packaging solutions in the future. Since the industry continues to look for cost -effective, protective and environmentally conscious packaging, market.

Conclusion

PP -woven bags, with its remarkable strength, wonderful stability properties and enormous versatility, are much more than containers. They are an integral part of global trade and trade, which ensures safe and efficient transport of countless products. From Staple PP bags for rice to large -scale PP FIBC bags, their applications expand all understandable industries. The dedication of a manufacturer of PP bag in Rajkot and similar manufacturers around the world ensures that these essential solutions meet modern logistics and sometimes sometimes develop environmental responsibility requirements. Their permanent tools emphasize his important role in the design of effective and durable supply chains.

Frequently Asked Questions

Question: Are PP woven bags really waterproof?

A: While PP-Woven bags are natural water repellent due to the nature of polypropylene, they are usually 100% waterproofing unless they are laminated or have an inner lining. Laminating provides a layer that prevents water penetration, suitable for them for products that require complete moisture safety.

Question: What is the specific lifetime of PP -Woven Poses Re -spared?

A: A lifetime of a re -pure bag PP -Woven bag depends much more depending on the intended use, the quality of the bag and how it is handled and stored. With proper care and avoidance of excessive UV exposure, a high quality PP-woven bags can live for dozens of applications, which significantly increases the usefulness compared to disposable options.

Question: Can PP woven bags are printed?

A: Yes, PP -Woven bags are very customized. Manufacturers can print logo, product information, branding and even complex designs on the bag, which can be used different printing techniques, including flexographic printing. This allows companies to use their packaging as an effective marketing tool and provide the necessary product details.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness