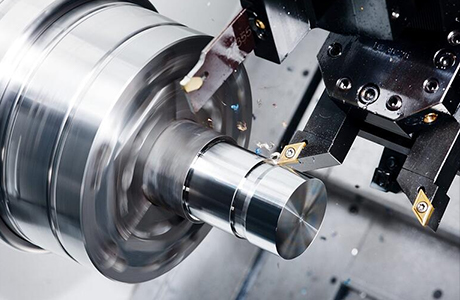

The cutting fluid used in the manufacturing process has a significant impact on the quality of aluminum alloy parts

As a result of their high toughness, ease of cutting, low weight, and low cost, parts made of aluminum alloy are becoming increasingly widespread in use. However, the texture of the aluminum alloy is soft, and it has a high degree of plasticity. During the cutting process, it is easy for the material to stick to the knife, resulting in a built-up edge on the tool. Welding on the knife edge can happen during high-speed cutting, which can cause the tool to lose its ability to cut, which in turn affects the machining accuracy and surface roughness. The thermal expansion coefficient of aluminum alloy is quite high, which means that the heat generated during cutting can easily lead to thermal deformation of the workpiece, which in turn reduces the accuracy of the machining process. Because of this, selecting the appropriate cutting fluid for the processing of aluminum alloys is of the utmost significance. It is not enough for it to have good lubricity and rust resistance; it also needs to have excellent cooling and the ability to be filtered. Therefore, the quality of the processing and the efficiency of the processing of parts made of aluminum alloy are closely related to the cutting fluid.

Machining aluminum alloy parts at high speeds, such as high-speed cutting, drilling, or other operations, can produce a significant amount of heat. In the event that the heat that is produced cannot be removed by the cutting fluid in a timely manner, the phenomenon known as sticking to the knife will take place, and even built-up edge will be seen. The machining roughness of the workpiece as well as the useful life of the tool will both be adversely affected as a result of this. In addition to this, the heat will cause the workpiece to become deformed, which will have a significant impact on the accuracy of the workpiece. As a result, the cutting fluid should be one that has a high level of lubricity and performs exceptionally well in terms of cooling performance.

The grinding process for aluminum alloy parts produces a significant amount of heat, and the debris produced by the grinding is of an extremely fine consistency. When choosing a cutting fluid, it is necessary to take into consideration not only how well the cutting fluid lubricates and cools, but also how easily it can be filtered. In the event that the viscosity of the chosen cutting fluid is too high, the wear debris will not be able to be deposited or filtered in a timely manner. As a result, the surface of the workpiece will be scratched as the cutting fluid circulates to the processing area, which will affect the surface's ability to be as smooth as possible. Because of this, selecting a cutting fluid that settles or a grinding fluid with a low viscosity should be done before performing fine or ultra-fine grinding.

It is not necessary to have very high machining accuracy in order online cnc machining service to perform routine low-speed grinding or cutting on parts made of aluminum alloy. Standard cutting fluids are sufficient for meeting production requirements. Cutting fluids that have excellent cleaning and cooling capabilities can be chosen from among these options. Choose a cutting fluid designed specifically for aluminum alloys if at all possible. Because the special aluminum alloy cutting fluid typically contains special aluminum inhibitors, which can ensure that the surface of the workpiece will not be damaged during the processing, we will refer to this fluid as "special aluminum alloy cutting fluid. ".

Emulsified cutting fluid, cutting fluid semi-synthetic cutting fluid, and fully synthetic cutting fluid are the three varieties of cutting fluids that are currently available on the market. Emulsified products, also known as emulsified oil or cutting oil, are oil-based products that have excellent lubricating properties but high viscosity and are not friendly to the environment. Cutting oil is another name for emulsified products. They are suited for the processing of aluminum alloy parts that need to online milling service have a high level of hardness but require a low level of workpiece precision. In addition, in order to achieve the effects of lubrication and the reduction of friction, as well as easy cooling and filtration, it is necessary to select products that have a viscosity that is relatively low and also contains anti-friction additives. Cutting oil, on the other hand, has a low flash point, produces a lot of smoke when it's being used, carries a high risk factor, evaporates quickly, and is expensive to use.

When selecting a cutting fluid, you need to pay attention to how well it prevents rusting because it is a product that is based on water. This is true whether the cutting fluid is semi-synthetic or fully synthetic. It is recommended to use cutting fluid with aluminum anti-rust agent during processing, especially for workpieces that have been stored for a long time between processes, because the pH value of cutting fluid is usually kept at 8-10. This is especially true for workpieces that have been stored for a long time between processes. When exposed to alkaline conditions, it corrodes very easily.

Cutting fluids, also known as grinding fluids and semi-synthetic cutting fluids, are products that are based on water and go by the names cutting fluids and fully synthetic cutting fluids, respectively. The features that are shared include an easy filtration process, a good cleaning performance, and an excellent cooling performance. In general, the lubricating performance of products that are only partially synthetic is superior to that of products that are fully synthetic. In modern times, the variety of uses for components made of aluminum alloy is continuously growing. It is necessary to choose cutting fluid sensibly in accordance with the various materials, processing methods, and quality requirements of aluminum alloy parts in order to guarantee the processing quality and efficiency of aluminum alloy parts. This is necessary in order to ensure the processing quality. because the quality of the processing and the efficiency of the processing of parts made of aluminum alloy are closely related to the cutting fluid.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness