Custom Moulded Solutions for Plastic Food Containers

An effective cooling system within the mould is crucial for controlling the cooling rate of the plastic. Uniform cooling prevents internal stresses and warping, which could lead to deformation or leakage in the final product.

Well-engineered cooling channels enable shorter cycle times, increasing production efficiency without sacrificing quality. Proper cooling also contributes to a smooth surface finish, which is important for the container’s aesthetic appeal and ease of cleaning.

To maximize productivity, many plastic food container moulds are designed with multiple cavities, allowing several containers to be formed in a single injection cycle. Multi-cavity moulds increase output while maintaining consistent quality across products.

Modular mould designs enable quick changes between different container styles or sizes, reducing downtime during production runs and offering flexibility to manufacturers responding to market demands.

The ultimate performance measure of a mould is its ability to consistently produce high-quality containers. This includes uniform wall thickness, smooth surface finish, accurate dimensions, and reliable sealing features.

Consistency is particularly critical in the food industry, where packaging must meet stringent safety and hygiene standards. Containers must be free from defects such as cracks, bubbles, or uneven edges that could harbor bacteria or cause leaks.

Cycle time refers to the total time required to produce one batch of containers, including injection, cooling, and ejection. Efficient moulds minimize cycle times without compromising quality, directly impacting manufacturing throughput and cost-effectiveness.

Optimized cooling channels, precise injection gate design, and smooth ejection mechanisms contribute to reducing cycle times, allowing manufacturers to meet high demand and tight delivery schedules.

Given the high volume of production in plastic food container manufacturing, mould maintenance is a critical consideration. Moulds must be designed for easy cleaning, inspection, and repair to minimize downtime.

https://www.food-container-mold.com/product/disposable-plastic-square-food-container-moulds/square-product-mold.html

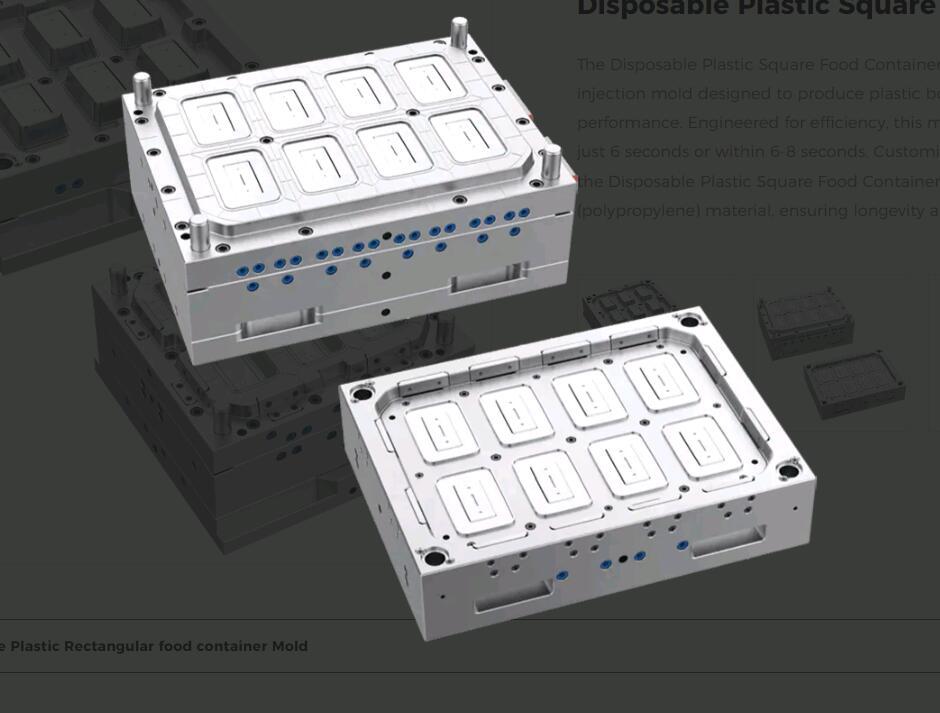

The Disposable Plastic Square Food Container Mold is a high-precision plastic injection mold designed to produce plastic boxes and lids with excellent sealing performance. Engineered for efficiency, this mold ensures a swift molding cycle of just 6 seconds or within 6-8 seconds. Customizable to meet specific requirements, the Disposable Plastic Square Food Container Mold is made from durable PP (polypropylene) material, ensuring longevity and reliability.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness