What Are the Best Shock Absorbing Casters Materials?

When transporting heavy or delicate equipment across rough or uneven surfaces, choosing the right shock absorbing casters can make all the difference. These specialized casters are engineered to reduce vibration and absorb impact—protecting your equipment and improving workplace safety.

In this guide, we’ll dive deep into the best materials used in shock absorbing casters, how they work, and which types are ideal for different applications. Whether you're outfitting carts, mobile workstations, or industrial dollies, you’ll walk away with a clear understanding of how to make the best choice for long-lasting, smooth operation.

Why Material Choice Matters for Shock Absorbing Casters

The effectiveness of shock absorbing caster wheels largely depends on the materials used in both the wheel and the shock-absorbing mechanism.

These materials directly affect:

- Load capacity

- Vibration control

- Floor protection

- Durability in demanding environments

- Choosing the wrong material can lead to poor performance, excessive wear, and even safety hazards.

Best Materials for Shock Absorbing Casters

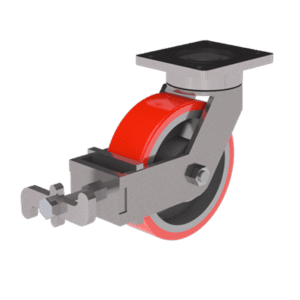

1. Polyurethane Wheels

Polyurethane is one of the most popular materials for shock absorbing caster wheels due to its balance of flexibility and toughness.

Pros:

- Excellent vibration dampening

- Non-marking, protects floors

- High load capacity

- Resistant to oil, grease, and chemicals

Best for: Warehouses, cleanrooms, and general industrial use.

2. Rubber Wheels

Rubber, particularly thermoplastic rubber (TPR), is highly effective for spring loaded casters where quiet, smooth motion is needed.

Pros:

- Superior shock absorption

- Ideal for uneven or outdoor terrain

- Quiet operation

- Affordable

Cons:

- Lower load capacity than polyurethane

- May wear faster under continuous use

Best for: Hospitals, labs, light industrial carts.

3. Steel Springs (in the Suspension Mechanism)

In heavy duty spring loaded casters, the internal steel springs play a vital role in shock absorption.

Benefits of high-quality steel springs:

- Withstand high weight loads

- Maintain consistent deflection under pressure

- Improve caster longevity

Used in combination with: Polyurethane or rubber wheels, depending on floor conditions.

4. Elastomer Wheels

Elastomers offer a mix of rubber-like cushioning with high resilience.

Pros:

- Strong rebound from impact

- Durable for outdoor or rugged use

- Moderate resistance to chemicals and water

Best for: Military, construction, or mining applications.

5. Nylon or Glass-Filled Nylon (less common for shock absorbing)

While nylon wheels are not known for shock absorption, when combined with a spring mechanism, they can still offer value where hard surfaces and heavy loads are expected.

Use with caution where delicate equipment is involved, as they offer minimal inherent vibration reduction.

6 Comparing Materials: Quick Reference

Polyurethane

- Shock Absorption: High

- Load Capacity: High

- Floor Protection: Excellent

- Durability: Excellent

- Best Application: Industrial, Cleanrooms

Rubber (TPR)

- Shock Absorption: Very High

- Load Capacity: Medium

- Floor Protection: Excellent

- Durability: Moderate

- Best Application: Healthcare, Light Industrial

Elastomer

- Shock Absorption: High

- Load Capacity: High

- Floor Protection: Good

- Durability: High

- Best Application: Military, Outdoor Use

- Steel Springs (used inside casters)

- Shock Absorption: Critical Support

- Load Capacity: High

- Floor Protection: N/A

- Durability: Excellent

- Best Application: Internal mechanism (casters)

Nylon

- Shock Absorption: Low

- Load Capacity: Very High

- Floor Protection: Poor

- Durability: Excellent

- Best Application: Heavy loads, hard floors

How to Choose the Right Shock Absorbing Caster

1. Evaluate Load Weight

- Use heavy duty spring loaded casters for loads over 1,000 lbs.

- Lighter carts can use rubber or elastomer wheels with basic spring systems.

2. Consider Floor Type

- Smooth floors: Polyurethane or TPR

- Uneven surfaces: Rubber or elastomer

- Rough outdoor terrain: Steel-framed casters with elastomer wheels

3. Factor in Mobility Requirements

- High-speed movement benefits from durable, low-resistance materials like polyurethane.

- For precise movement (e.g., in labs), go for rubber or spring-enhanced casters.

4. Understand Environmental Conditions

- Wet or chemical-prone environments call for corrosion-resistant materials (e.g., sealed polyurethane, stainless components).

Spring Loaded vs. Shock Absorbing Casters: What's the Difference?

While often used interchangeably, they are not always the same.

- Spring loaded casters include a mechanical spring to absorb shock.

- Shock absorbing casters may rely on material properties or a combination of springs and resilient wheels.

For heavy duty industrial use, a combination of both spring mechanisms and shock-absorbing wheel materials is ideal.

FAQ: Shock Absorbing Casters

What are the advantages of spring loaded casters over standard casters?

Spring loaded casters offer better vibration control, extend equipment life, and enhance safety—especially in environments with uneven flooring or sensitive loads.

Can I retrofit existing carts with shock absorbing caster wheels?

Yes, as long as the mounting plate or stem is compatible and the new casters meet the load and application requirements.

Are heavy duty spring loaded casters worth the investment?

Absolutely. In high-load or high-value transport scenarios, the reduced equipment wear and smoother operation can offset initial costs quickly.

Conclusion

Choosing the right material for your shock absorbing casters can significantly improve mobility, safety, and equipment longevity in industrial and commercial settings. Whether you prioritize heavy load capacity, quiet operation, or superior shock absorption, materials like polyurethane, rubber, elastomers, and steel springs offer targeted advantages for different needs.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness