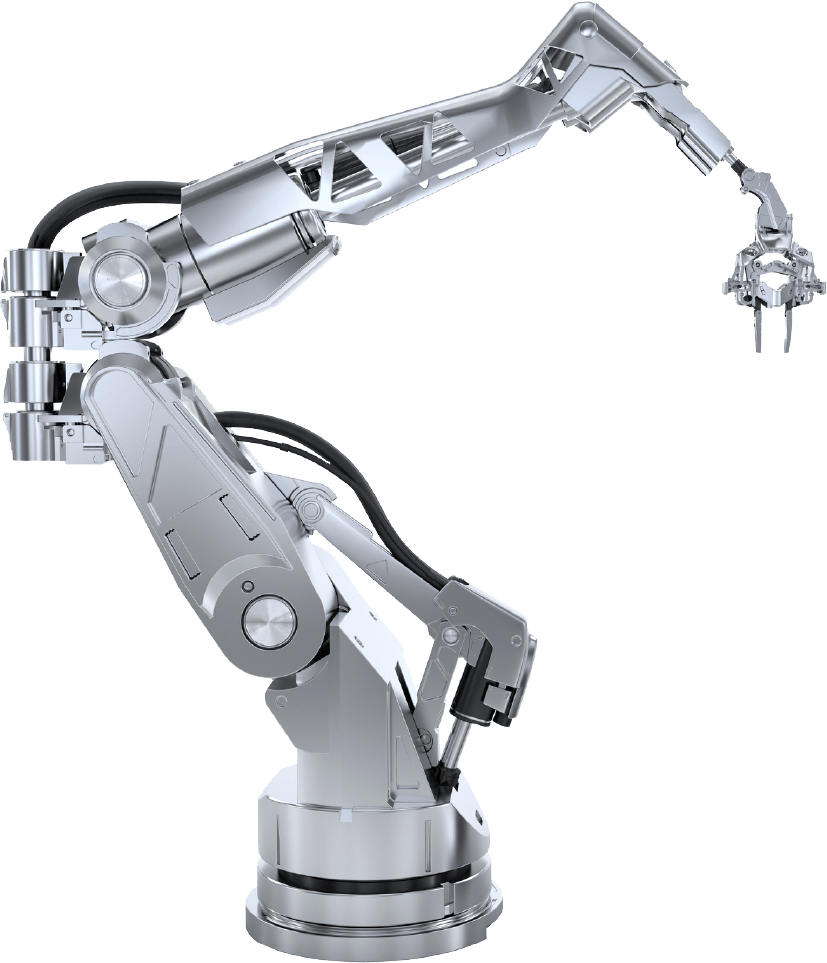

Robotic Arms Market Overview: Key Trends, Growth Drivers, and Future Prospects in Automation

The robotic arms market is evolving at a rapid pace, driven by technological advancements, increasing demand for automation, and the expansion of robotics across various industries. From manufacturing to healthcare, logistics, and agriculture, robotic arms are becoming indispensable tools that drive efficiency, enhance precision, and reduce operational costs. This article provides an in-depth overview of the robotic arms market, examining the key trends, growth drivers, and future prospects shaping this dynamic sector.

1. Market Overview

The robotic arms market has seen significant growth in recent years. Initially, robotic arms were mostly confined to large-scale manufacturing environments, particularly in the automotive industry. However, with the rapid development of advanced robotics technology, the market for robotic arms has expanded across various sectors. The adoption of robotic arms is increasing in industries like healthcare, electronics, food processing, logistics, agriculture, and more. The flexibility, precision, and speed that robotic arms provide are making them indispensable for operations ranging from assembly lines to complex tasks like surgery and logistics automation.

These robots are not only designed to perform repetitive tasks but can now adapt to a variety of complex, high-precision functions. This shift in capability is transforming industries and driving the robotic arms market into new, uncharted territory. The versatility of robotic arms allows them to function in environments that were previously challenging for traditional automation solutions.

2. Key Growth Drivers

Several key factors are driving the growth of the robotic arms market:

a. Increased Demand for Automation

One of the most significant drivers of growth in the robotic arms market is the increasing demand for automation. Industries around the world are focusing on automating their processes to improve productivity, reduce labor costs, and enhance efficiency. Robotic arms offer the precision and speed required for automating tasks like assembly, welding, painting, material handling, and packaging, among others. The need for faster and more efficient production processes is pushing companies to adopt robotic arms in various sectors.

b. Technological Advancements

The continuous advancements in robotics technology are another major driver behind the growth of the robotic arms market. Robotics manufacturers are increasingly incorporating artificial intelligence (AI), machine learning (ML), sensors, and advanced control systems into robotic arms, enabling them to perform more complex tasks. AI-driven robotic arms can learn and adapt to their environment, making them more efficient and versatile. As AI and robotics technology advance, robotic arms are becoming more capable of performing high-precision tasks, further boosting their adoption in industries like healthcare and electronics.

c. Cost Reduction and Efficiency Gains

The cost of robotic arms has decreased significantly over the years, making them more accessible to businesses of all sizes. Lower production costs, coupled with a decrease in the price of key components, have made robotic arms a more attractive investment for small and medium-sized enterprises (SMEs). The ability of robotic arms to enhance operational efficiency, reduce human error, and lower labor costs makes them a valuable asset for businesses looking to stay competitive in an increasingly automated world.

Additionally, robotic arms provide a rapid return on investment (ROI). As businesses adopt automation technologies, they see immediate gains in productivity, which translates into higher profit margins and faster payback periods.

d. Labor Shortages and Safety Concerns

Labor shortages, especially in developed countries with aging populations, have created a need for automation in various sectors. Industries like manufacturing and logistics are increasingly turning to robotic arms to address these shortages. Robotic arms can perform repetitive, labor-intensive tasks without requiring a skilled workforce, allowing companies to maintain productivity even in the face of a shrinking labor pool.

Robotic arms also help improve workplace safety. By taking over dangerous tasks such as welding, painting, and heavy lifting, they reduce the risk of workplace injuries. This trend toward safer work environments is another key driver of the robotic arms market.

3. Industry Applications and Trends

The versatility of robotic arms makes them suitable for a wide range of industries. Below are some key sectors where robotic arms are being adopted:

a. Manufacturing and Automotive

The manufacturing industry has long been the largest consumer of robotic arms. In automotive manufacturing, robotic arms are used for tasks like welding, painting, and assembling parts. The need for faster production times, greater precision, and higher product quality is driving the increased use of robotic arms in the automotive sector. As manufacturing processes become more complex, the adoption of robotic arms is expected to continue growing in this sector.

b. Healthcare and Medical Robotics

The healthcare industry is seeing a growing adoption of robotic arms, particularly in surgery, rehabilitation, and medical device manufacturing. Robotic-assisted surgery allows for more precise procedures with minimal invasiveness, leading to faster recovery times and better patient outcomes. Robotic arms are also used in physical therapy, prosthetics, and drug development, with the potential to revolutionize healthcare practices.

c. Logistics and E-Commerce

In logistics and e-commerce, robotic arms are increasingly used in warehouses and distribution centers for tasks such as sorting, picking, and packing goods. As e-commerce continues to grow, there is a pressing need for faster, more efficient order fulfillment processes. Robotic arms help meet this demand by automating repetitive tasks and increasing the speed and accuracy of warehouse operations.

d. Agriculture and Food Processing

Robotic arms are also making their way into agriculture and food processing. In agriculture, robotic arms are being used for tasks such as harvesting crops, planting seeds, and pruning. In food processing, they are employed for sorting, packaging, and quality control. These applications help reduce labor costs and improve efficiency in an industry traditionally reliant on manual labor.

4. Challenges in the Robotic Arms Market

While the robotic arms market presents significant growth opportunities, there are several challenges that businesses must overcome:

a. High Initial Investment

Although the cost of robotic arms has decreased over the years, the initial investment required to implement robotic systems can still be prohibitive for small businesses. The cost of purchasing, integrating, and maintaining robotic arms can be substantial, which may deter companies from adopting these technologies. However, as the price of robotic arms continues to fall and the benefits of automation become more evident, this challenge may become less of a barrier.

b. Integration and Technical Complexity

Integrating robotic arms into existing operations can be complex and may require technical expertise. Businesses must ensure that robotic arms can be seamlessly incorporated into their workflows, which may involve system upgrades or modifications to existing equipment. This integration complexity can slow the adoption of robotic arms in certain industries.

c. Security Concerns

As robotic arms become increasingly connected to the internet and other systems, concerns about cybersecurity are emerging. Protecting robotic systems from hacking or cyberattacks is critical, particularly as these technologies become more deeply embedded in industrial operations.

5. Future Outlook

The robotic arms market is expected to continue its growth trajectory over the coming years. Advances in AI, machine learning, and robotics technology will enable robotic arms to become more intelligent, adaptable, and cost-effective. As the demand for automation continues to rise across industries, robotic arms will play a pivotal role in shaping the future of manufacturing, healthcare, logistics, and more.

With their ability to improve productivity, reduce costs, and enhance precision, robotic arms are poised to become a fundamental component of the global economy. As businesses increasingly embrace automation, the robotic arms market will continue to evolve, presenting new opportunities for innovation and growth.

Conclusion

The robotic arms market is on an exciting growth path, fueled by technological advancements, the need for automation, and expanding applications across various industries. As more sectors adopt robotic arms to improve efficiency, reduce costs, and maintain competitiveness, the market is set to flourish in the coming years. By understanding the key trends, growth drivers, and challenges in this sector, businesses can better navigate the evolving landscape and capitalize on the immense opportunities presented by robotic arms.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness