Understanding Boring in Machining and Its Role in Producing Precision Holes in Manufacturing

what is boring in machining is a vital process used to fine-tune and enlarge pre-existing holes in a workpiece with extreme accuracy. Unlike drilling, which creates a hole from solid material, boring is a secondary operation that enhances the size, geometry, and surface finish of that hole. This operation is essential in many industries including aerospace, automotive, and industrial equipment manufacturing where high tolerance and precision are critical to part performance.

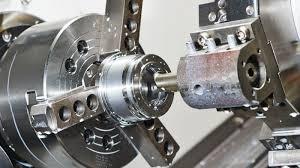

The boring process is performed using a single-point cutting tool that rotates inside the hole, gradually removing small amounts of material. This tool is typically mounted on a boring bar and guided by either a manual lathe or an advanced CNC machine. In modern machining shops, CNC boring machines are favored for their ability to deliver consistent, repeatable results at high speed with exceptional accuracy.

Boring allows machinists to achieve tighter tolerances than other hole-making methods. The surface finish created through boring is smoother, and the final diameter can be controlled within microns. This makes it an ideal process when manufacturing parts that will house rotating shafts, bearings, pistons, or other mechanical components that require an exact fit. The process not only improves the roundness and straightness of the hole but also aligns it perfectly with other features of the part.

There are various types of boring techniques such as line boring, back boring, and contour boring, each suited for specific part requirements. Line boring is commonly used to align multiple holes along the same axis in larger workpieces like engine blocks or structural components. Back boring is performed from the opposite end of the hole, which is helpful when access is limited. Contour boring allows for machining of holes with variable internal diameters, often found in complex mechanical parts.

Choosing the right cutting tool for boring is essential. High-speed steel tools may be used for softer materials, while carbide-tipped or ceramic tools are better suited for hard metals and high-production environments. Cutting fluid is often applied during the process to reduce heat, extend tool life, and ensure a cleaner finish.

One of the lesser-known advantages of boring is its corrective capability. When a drilled hole is slightly off-center or out of round, boring can bring it back to precise alignment and finish. This corrective function makes boring a reliable choice in repair work and custom machining tasks.

As design requirements become increasingly complex and tolerance limits grow tighter, boring remains a key machining operation. Its adaptability to different materials, shapes, and machine types ensures it continues to play a foundational role in high-precision manufacturing. Whether creating parts for aviation engines or hydraulic systems, boring helps engineers and machinists meet the highest quality and performance standards.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness