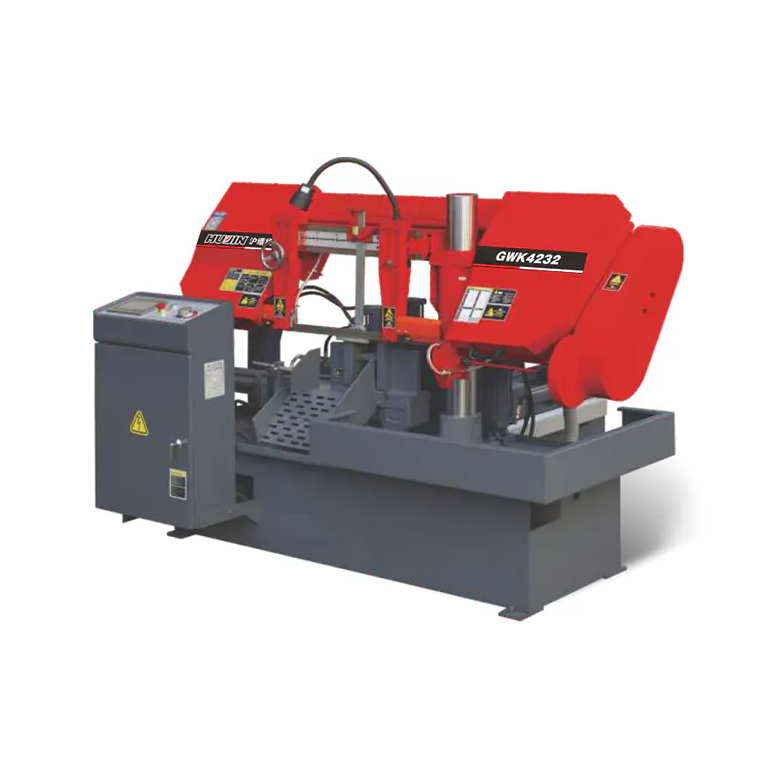

Optimizing Performance of Horizontal Band Saw Machine for Efficient Cutting Operations

The Horizontal Band Saw Machine (HBSM) is a critical piece of equipment in the metalworking industry, known for its precision and efficiency in cutting operations. To maximize the cutting efficiency of an HBSM, several factors must be considered, including blade selection, Horizontal Band Saw machine maintenance, feed rate, and operator training. This article delves into these aspects and offers insights into how they can be optimized to enhance the performance of the Horizontal Band Saw Machine.

One of the primary ways to improve the efficiency of a Horizontal Band Saw Machine is by selecting the appropriate blade for the material being cut. The choice of blade can significantly impact the cutting speed and surface finish. A blade that is too narrow may cause excessive friction and slow down the cutting process, while a blade that is too wide may not provide the required precision. Therefore, understanding the properties of the material and matching them with the right blade is crucial for the HBSM.

Maintenance is another key factor that affects the efficiency of the Horizontal Band Saw Machine. Regular servicing, including blade tension checks, alignment verification, and lubrication, ensures that the machine operates at peak performance. A well-maintained HBSM will have less downtime due to mechanical failures, resulting in increased productivity and cost savings.

The feed rate of the Horizontal Band Saw Machine is another parameter that can be adjusted to improve cutting efficiency. The feed rate refers to the speed at which the material is moved through the blade. Too slow a feed rate can lead to excessive blade wear and poor cut quality, while too fast a feed rate can cause the blade to bind and potentially break. Finding the optimal feed rate for the specific material and blade combination is essential for achieving the best cutting efficiency.

The skill level of the operator also plays a significant role in the efficiency of the Horizontal Band Saw Machine. An operator who is well-trained in the use of the machine can make adjustments on the fly to compensate for variations in material thickness or hardness, ensuring that the machine continues to cut efficiently. Training programs that focus on the nuances of blade selection, Horizontal Band saw machine operation, and cutting techniques can lead to significant improvements in overall productivity.

In addition to these factors, the use of cutting fluids can also enhance the efficiency of the Horizontal Band Saw Machine. Cutting fluids help to cool the blade and lubricate the cut, reducing friction and heat build-up. This can lead to longer blade life and faster cutting speeds, ultimately improving the efficiency of the HBSM.

The use of modern control systems in HBSMs can also contribute to increased cutting efficiency. Advanced controls can automate the cutting process, ensuring consistent feed rates and blade speeds, regardless of the operator's skill level. These systems can also monitor the health of the Horizontal Band Saw machine, alerting operators to potential issues before they result in costly downtime.

Finally, the layout of the workshop and the integration of the HBSM into the production line can impact its efficiency. Streamlining the workflow so that materials can be quickly and easily loaded and unloaded from the HBSM can reduce idle time and increase overall throughput.

In conclusion, the cutting efficiency of a Horizontal Band Saw Machine can be significantly improved through a combination of blade selection, regular maintenance, optimal feed rates, operator training, the use of cutting fluids, advanced control systems, and efficient workshop layout. By focusing on these areas, manufacturers can ensure that their HBSMs operate at peak efficiency, leading to increased productivity and cost savings.

Cutting Capacity(mm) : Round material Φ500 Plate 500x500

Blade speed(m/min): 30,60,80

Blade Size(mm):1.3*41*6200

Single feeding travel(mm):500

Motor main output(kw): 4-6

Hydraulic(kw):1.5

Coolant pump(kw): 0.09

Machine Size(LxWxH)(mm): 3000*2200*1950

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness