Burn-off Oven Market: Future Trends Shaping the Industry

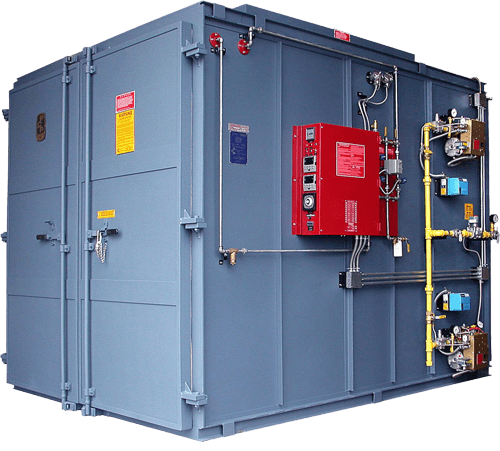

The global Burn-off Oven Market is poised for significant transformation, driven by growing environmental awareness, stricter emission regulations, and the increasing demand for efficient and sustainable industrial cleaning solutions. Burn-off ovens, also known as pyrolysis or heat-cleaning ovens, are used to remove coatings, resins, and contaminants from metal parts through high-temperature thermal decomposition. As industries across sectors seek greener, safer, and more cost-effective alternatives to chemical cleaning, the burn-off oven market is expected to expand in new directions.

This article delves into the key future trends that are set to shape the burn-off oven market in the coming years.

1. Rising Demand for Eco-Friendly Industrial Solutions

One of the most significant trends in the burn-off oven market is the increased focus on environmental sustainability. As global industries shift toward green manufacturing practices, burn-off ovens present a compelling solution by eliminating the use of harsh chemicals traditionally employed in cleaning and coating removal. The thermal decomposition process emits fewer pollutants and supports safe disposal of waste.

Going forward, demand for ovens with improved emission control systems, such as integrated afterburners and catalytic converters, will grow, enabling manufacturers to meet environmental regulations without compromising efficiency.

2. Technological Advancements in Automation and Controls

The future of the burn-off oven market lies in automation and smart technologies. Modern ovens are increasingly being equipped with programmable logic controllers (PLCs), real-time temperature monitoring, digital interfaces, and IoT-enabled sensors. These innovations ensure greater precision, safety, and process optimization, reducing the margin for error and human intervention.

The move towards fully automated ovens capable of self-adjusting heat cycles based on load types and sizes is expected to accelerate. Additionally, cloud-based monitoring and predictive maintenance will help reduce downtime and improve the overall lifecycle of the equipment.

3. Expansion into Emerging Markets

While North America and Europe remain the primary markets for burn-off ovens due to stringent regulations and advanced manufacturing infrastructure, emerging economies in Asia-Pacific, Latin America, and the Middle East are expected to show rapid growth. Industrialization, increasing production volumes, and rising environmental consciousness are pushing companies in these regions to explore sustainable equipment.

Governments in countries like India, China, and Brazil are offering incentives for cleaner industrial technologies, which is expected to boost demand for burn-off ovens across sectors like automotive, aerospace, and general manufacturing.

4. Customization and Modular Designs

As industries become more diverse and specialized, there is a growing demand for customized burn-off oven solutions that meet specific operational requirements. Future ovens will feature modular designs that allow users to scale up or modify their systems based on production needs, available space, and budget constraints.

Manufacturers are increasingly offering tailored solutions for niche applications such as motor cleaning, filter regeneration, and electronic component recovery, making the technology more versatile and appealing to a broader customer base.

5. Integration with Circular Economy Practices

The shift towards circular economy models is influencing the burn-off oven market. As companies strive to recover, reuse, and recycle components, burn-off ovens are playing a vital role in cleaning and refurbishing used parts. This is especially prevalent in industries like automotive, where remanufacturing of engines and other metal components is becoming more common.

Future trends point toward ovens being integrated into remanufacturing and recycling lines, streamlining operations and maximizing material recovery. This alignment with sustainability goals positions burn-off ovens as essential tools in closed-loop production systems.

6. Increased Emphasis on Workplace Safety and Compliance

With growing awareness around worker safety and occupational health, future burn-off ovens will be designed with enhanced safety features, such as automatic shut-off systems, insulation improvements, smoke suppression technology, and real-time hazard detection.

Compliance with standards from bodies such as OSHA, EPA, and CE will become a competitive differentiator, prompting manufacturers to invest in R&D for safer, more user-friendly designs. Ergonomics and user interfaces will also evolve to reduce training time and improve operator efficiency.

7. Growth in Aftermarket Services and Leasing Models

The market is witnessing a surge in demand for aftermarket services such as maintenance, performance upgrades, remote diagnostics, and retrofitting of emission control systems. As capital-intensive purchases become more scrutinized, many businesses are also exploring leasing or rental models that offer flexible ownership and lower upfront costs.

This shift could open new revenue streams for manufacturers and service providers while making the technology more accessible to small and medium-sized enterprises.

8. Diversification of Application Areas

While traditionally associated with automotive and metal industries, burn-off ovens are finding new applications in electronics recycling, textile processing, 3D printing cleanup, and even art restoration. This diversification is expected to widen the market base and spur innovation in terms of temperature control, chamber design, and waste handling.

Future ovens may be optimized for delicate materials, precision cleaning, or integration into zero-waste manufacturing lines, further expanding their relevance across industries.

Conclusion

The Burn-off Oven Market is on a growth trajectory, fueled by technological innovation, regulatory compliance, and a global push for cleaner industrial practices. As industries modernize and demand scalable, intelligent, and eco-conscious cleaning solutions, burn-off ovens are emerging as critical assets.

Manufacturers that invest in R&D, flexible product offerings, and digital integration will be well-positioned to lead the market in the coming years. The next decade promises exciting developments in this niche yet vital sector of industrial equipment.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness