GALVANIZED COILS VS. OTHER COATING METHODS: A COMPARATIVE ANALYSIS

When it comes to corrosion protection, choosing the right coating method is crucial. Galvanized coils have long been recognized for their exceptional performance in safeguarding steel from rust and corrosion. However, there are other coating methods available in the market. In this article, we will conduct a comparative analysis of galvanized coils against other coating methods, highlighting the advantages and applications of galvanized coils and why AoFeng's galvanized coils stand out in terms of corrosion protection, durability, and cost-effectiveness.

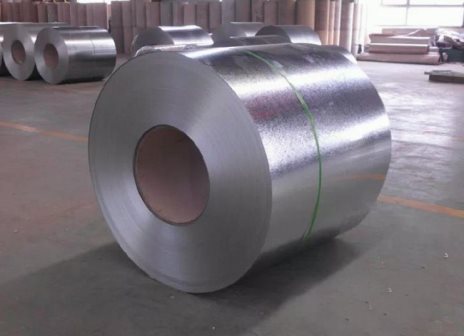

Understanding Galvanized Coils

Galvanized coils are steel coils that have undergone a galvanization process, where a protective layer of zinc is applied to the surface. This zinc coating acts as a barrier, shielding the underlying steel from corrosive elements such as moisture, chemicals, and atmospheric conditions.

Comparative Analysis: Galvanized Coils vs. Other Coating Methods

1.Galvanized Coils vs. Paint Coatings

Paint coatings are commonly used for corrosion protection. While paint can provide an aesthetic finish, it lacks the durability and longevity offered by galvanized coils. Paint coatings are susceptible to chipping, cracking, and peeling, leaving the underlying steel vulnerable to corrosion. In contrast, galvanized coils offer a robust and sacrificial layer of zinc that provides long-lasting protection, even in harsh environments. AoFeng's galvanized coils excel in durability, ensuring reliable corrosion protection for extended periods.

2.Galvanized Coils vs. Powder Coatings

Powder coatings have gained popularity due to their environmental friendliness and versatility. However, powder coatings may not offer the same level of corrosion protection as galvanized coils. Powder coatings are prone to chipping and scratching, compromising the integrity of the coating and exposing the steel to corrosion. Galvanized coils, on the other hand, provide a continuous and uniform layer of zinc that acts as a barrier against corrosive elements. AoFeng's galvanized coils offer enhanced resistance to rust and corrosion, ensuring long-term durability.

3.Galvanized Coils vs. Organic Coatings

Organic coatings, such as epoxy or polyurethane coatings, are commonly used for corrosion protection in various industries. While organic coatings can provide effective protection, they may not match the durability and cost-effectiveness of galvanized coils. Organic coatings require regular maintenance and reapplication to maintain their effectiveness, adding to the overall cost. Galvanized coils, with their sacrificial zinc layer, offer long-lasting corrosion protection without the need for frequent maintenance. AoFeng's galvanized coils provide a cost-effective solution for industries seeking reliable and durable corrosion protection.

Advantages and Applications of Galvanized Coils

1.Construction Industry:

Galvanized coils are widely used in the construction industry for applications such as roofing, structural components, and infrastructure projects. The durability and corrosion resistance of galvanized coils make them an ideal choice for long-lasting structures. AoFeng's galvanized coils offer exceptional protection against rust and corrosion, ensuring the integrity of construction projects.

2.Automotive Manufacturing:

The automotive industry relies on galvanized coils for corrosion protection in various vehicle components. From body panels to chassis parts, galvanized coils ensure the longevity and safety of automobiles, even in harsh weather conditions. AoFeng's galvanized coils are engineered to meet the stringent requirements of the automotive industry, providing reliable corrosion protection.

3.Manufacturing and Industrial Applications:

Galvanized coils find applications in manufacturing processes, including appliances, electrical enclosures, industrial machinery, and more. The corrosion resistance of galvanized coils ensures the longevity and reliability of these products in demanding environments. AoFeng's galvanized coils offer excellent protection against rust and corrosion, contributing to the overall performance and durability of manufactured goods.

Conclusion

In the comparative analysis of galvanized coils against other coating methods, galvanized coils emerge as a superior choice for corrosion protection, durability, and cost-effectiveness. While other coating methods may have their advantages, galvanized coils offer long-lasting protection, even in harsh environments. AoFeng's galvanized coils excel in providing reliable corrosion protection, ensuring the longevity and integrity of structures and products in diverse industries.

The Benefits of Galvanized Coils in Corrosion Protection

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness