Understanding the Pivotal Role of Winch Relays in Emergency Recovery Scenarios

Winch relays are integral components in the realm of heavy-duty machinery and vehicle operations, where they play a crucial role in managing the flow of power and control signals within winch systems. These devices are engineered to ensure that the winch operates at peak efficiency and safety, making them indispensable in various industries such as construction, automotive recovery, and marine operations.

The primary function of a winch relay is to act as an intermediary between the power source and the winch motor. By doing so, it amplifies the control signals and manages the heavy electrical loads that are typical in winch applications. This is particularly important in scenarios where a winch is required to lift or pull heavy loads, as the relay helps to prevent damage to the control system and ensures that the winch operates smoothly.

One of the key benefits of using winch relays is their ability to protect the winch system from electrical faults. When a winch is subjected to high levels of current, the relay can interrupt the circuit, preventing potential damage to the motor and other components. This protective feature is crucial, as it safeguards the investment in winch equipment and reduces the likelihood of costly repairs.

Winch relays also enhance the controllability of winch systems. By providing a clear and strong signal path, they ensure that the winch responds accurately to operator commands. This is especially important in situations where precise control is necessary, such as in the recovery of vehicles after an accident or in the lifting of heavy construction materials.

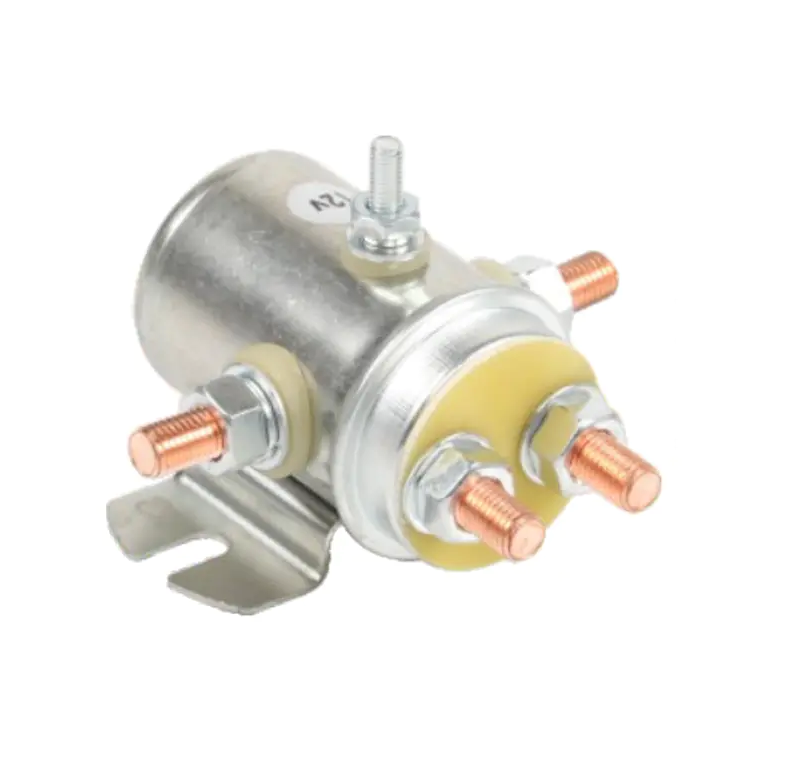

The design of winch relays is tailored to withstand the rigors of outdoor environments and the demands of heavy machinery. They are typically housed in robust casings that protect the internal components from dirt, moisture, and physical damage. This durability is essential in ensuring that the relay continues to function reliably, even in the most challenging conditions.

In terms of performance, winch relays contribute to the efficiency of winch operations by ensuring that power is delivered consistently. This is achieved through the use of high-quality electrical contacts that maintain a secure connection even under heavy loads. The result is a winch system that operates with minimal power loss and maximum torque, which is vital for tasks that require sustained pulling force.

Maintenance of winch relays is also a critical aspect of ensuring their longevity and effectiveness. Regular inspection and replacement of relays when necessary can prevent unexpected failures in the winch system. This proactive approach to maintenance is essential in industries where downtime can result in significant financial losses.

In conclusion, winch relays are pivotal in the operation of winch systems, providing a reliable means of managing power and control signals. Their ability to protect against electrical faults, enhance controllability, and ensure efficient power delivery makes them an essential component in any winch setup. By understanding the importance of winch relays and maintaining them properly, operators can maximize the performance and safety of their winch equipment, reducing the risk of accidents and equipment failure. The integration of winch relays into winch systems is a testament to the ongoing evolution of technology in the heavy machinery industry, where reliability and efficiency are paramount.

12V/24V

OEM: SW-933 46-2287 440003 24401-01

NAME: Capstan relay

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness