Camel Milk Market Supply Chain Analysis: From Farm to Consumer

Introduction

The supply chain of camel milk market is a crucial aspect of the industry, determining product availability, quality, and affordability. From camel farms to the final consumer, various stages involve production, processing, distribution, and retail. This article provides an in-depth analysis of the camel milk supply chain and the factors influencing its efficiency.

1. Camel Farming and Milk Production

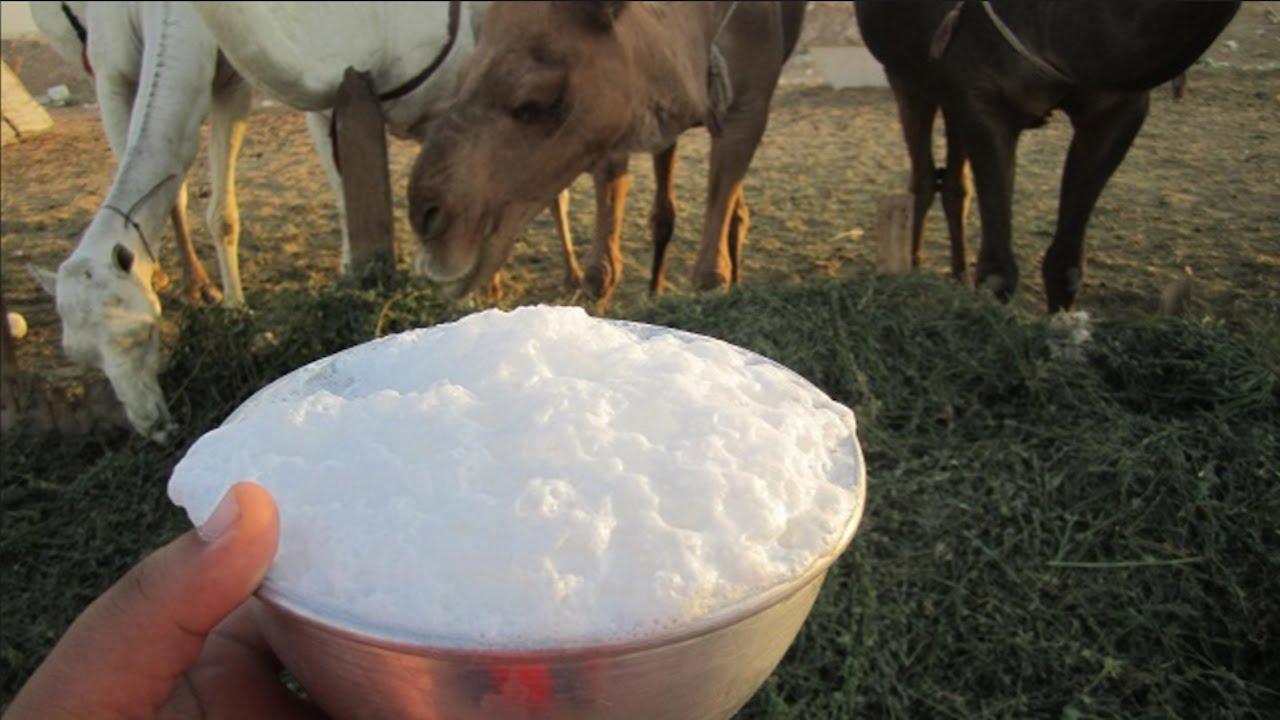

Camel milk production begins at specialized farms, primarily located in the Middle East, Africa, and parts of Asia. The key aspects of this stage include:

-

Camel Breeding and Health Management: Maintaining healthy camels is essential for optimal milk production.

-

Milk Collection: Camels produce lower milk yields compared to cows, making efficient collection methods necessary.

-

Hygiene and Safety Standards: Proper sanitation and adherence to health regulations ensure the quality of raw camel milk.

2. Processing and Pasteurization

Once collected, camel milk undergoes processing to enhance shelf life and safety. Processing includes:

-

Pasteurization: Reduces harmful bacteria while retaining nutritional benefits.

-

Powdering and Drying: Used to produce camel milk powder for extended storage and easier global distribution.

-

Flavoring and Packaging: Some products undergo further enhancement, such as the addition of flavors or fortification with vitamins.

3. Distribution and Logistics

Efficient transportation is vital for delivering camel milk to consumers while maintaining its freshness. Key challenges and strategies include:

-

Cold Chain Management: Fresh and pasteurized camel milk require refrigeration during transport.

-

Regional and International Exporting: Different countries have varying regulations affecting the global trade of camel milk.

-

Retail Partnerships: Collaborations with supermarkets, specialty stores, and online retailers help expand market reach.

4. Retail and Consumer Access

Camel milk products reach consumers through multiple retail channels, including:

-

Supermarkets and Grocery Stores: Offer fresh, powdered, and flavored camel milk.

-

Online E-Commerce Platforms: Enable global access to camel milk, particularly for niche markets.

-

Health and Specialty Stores: Cater to consumers looking for alternative dairy and functional foods.

-

Pharmacies and Wellness Centers: Sell camel milk products for medical and therapeutic applications.

5. Challenges in the Camel Milk Supply Chain

Despite growing demand, the supply chain faces several challenges:

-

High Production Costs: Limited camel milk yield and specialized farming increase production expenses.

-

Regulatory Barriers: Import/export restrictions and compliance issues affect market expansion.

-

Limited Consumer Awareness: Many consumers are still unfamiliar with camel milk’s benefits.

-

Cold Chain Infrastructure: Maintaining refrigeration during transport is challenging, especially in emerging markets.

6. Future Trends and Innovations

-

Advancements in Processing Technology: Improved pasteurization and powdering methods to enhance shelf life.

-

Blockchain for Traceability: Ensuring quality and authenticity through digital tracking.

-

Sustainable and Ethical Farming Practices: Promoting eco-friendly and humane camel dairy production.

Conclusion

The camel milk supply chain is complex, involving multiple stages from farm to consumer. While challenges exist, innovations in processing, distribution, and awareness campaigns are improving market accessibility. As demand for camel milk grows, optimizing the supply chain will be essential for sustained industry success.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness