What is a Jaw Crusher?

What is a Jaw Crusher?

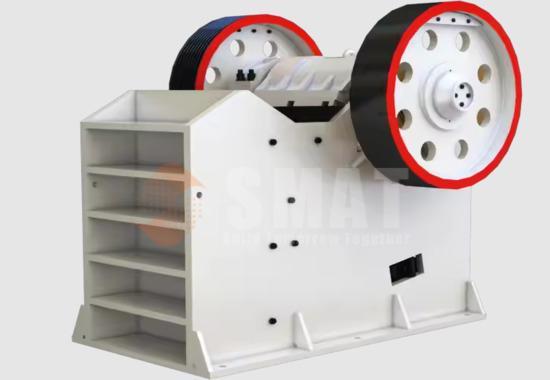

A jaw crusher is a type of primary crusher used in mining, construction, and demolition industries to break down large materials (such as rocks, ores, and concrete) into smaller, manageable sizes. It works on a compression principle, where material is crushed between two jaw plates—one fixed and one movable.

1. Structure & Working Principle

A jaw crusher typically consists of:

- Fixed Jaw Plate: Remains stationary during operation.

- Movable Jaw Plate: Moves back and forth to crush material.

- Eccentric Shaft: Drives the movement of the movable jaw.

- Toggle Plate: Provides safety by allowing the crusher to release uncrushable material.

- Flywheel & Pulley: Helps in energy transfer and balance.

Working Principle

- Material is fed into the top opening of the crusher.

- The movable jaw moves towards the fixed jaw, applying compressive force to break the material.

- The crushed material exits through the bottom discharge opening.

- The process repeats until the desired size is achieved.

2. Types of Jaw Crushers

There are two main types:

① Single Toggle Jaw Crusher

- Uses one toggle plate for movement.

- Simpler design, less maintenance.

- More efficient for softer materials.

② Double Toggle Jaw Crusher

- Uses two toggle plates.

- Provides greater crushing force, ideal for hard materials.

- More complex design but durable.

3. Advantages of Jaw Crushers

✔ High Efficiency: Capable of handling large-sized materials.

✔ Simple Design: Fewer components, making maintenance easier.

✔ Durability: Can withstand high impact forces.

✔ Versatility: Suitable for mining, construction, and recycling applications.

4. Applications of Jaw Crushers

🔹 Mining Industry: Crushing ores and minerals.

🔹 Construction: Breaking down concrete and demolition waste.

🔹 Aggregate Production: Processing sand, gravel, and stones.

🔹 Recycling: Crushing asphalt, bricks, and glass.

Conclusion

A jaw crusher is a powerful and reliable machine for crushing materials efficiently. Its simple design, durability, and high efficiency make it widely used in various industries. Would you like recommendations on specific models or brands? Smat machine will give you a price.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness