Transform Your Business with the Power of a Fiber Laser Engraver

In today's fast-paced industrial landscape, precision and efficiency are paramount. One tool that has revolutionized the marking and engraving process is the fiber laser engraver. Known for its versatility and unmatched precision, fiber laser technology is becoming increasingly popular among businesses looking to enhance their product offerings. In this post, we will explore the numerous benefits of fiber laser engravers, their applications, and how they can elevate your business to new heights.

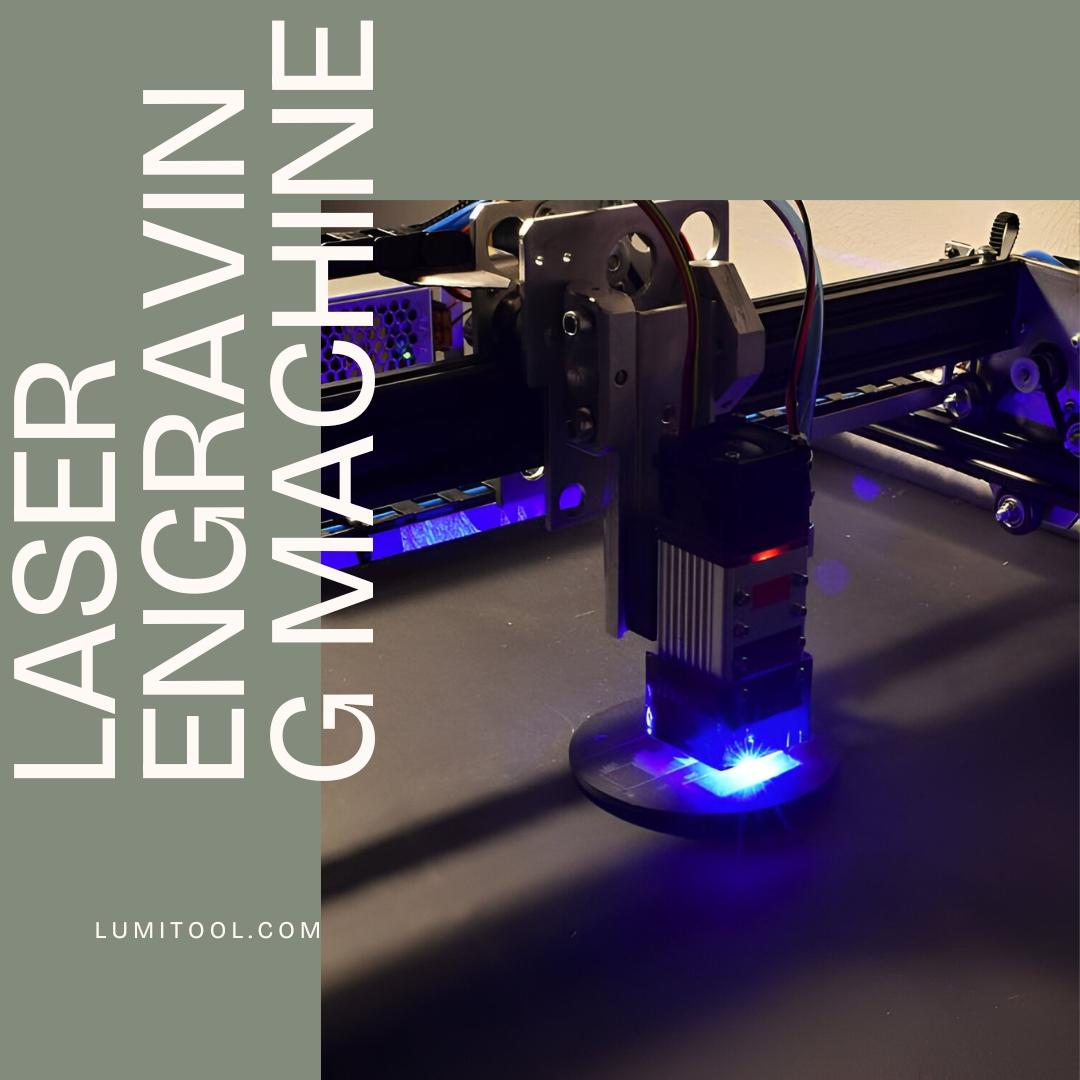

What is a Fiber Laser Engraver?

A fiber laser engraver utilizes a high-powered laser beam generated from a fiber optic cable to engrave or mark materials with exceptional precision. Unlike traditional laser engravers that use CO2 or solid-state lasers, fiber lasers are particularly effective for marking metals and other challenging materials. The compact design and high efficiency of fiber laser technology make it an ideal choice for various industrial applications.

Key Benefits of Fiber Laser Engravers

-

High Precision and Accuracy

Fiber laser engravers are renowned for their precision. With a resolution of up to 8K and a granularity of 0.001mm, these machines can create intricate designs and fine details that are often unattainable with other engraving methods. This level of accuracy is crucial for industries that require meticulous markings, such as electronics and aerospace. -

Versatility Across Materials

One of the standout features of fiber laser engravers is their ability to work on a wide range of materials including metals like stainless steel, aluminum, and brass, as well as plastics and ceramics. This versatility allows businesses to expand their product offerings without needing multiple machines, ultimately saving space and costs. -

Durability of Markings

The markings produced by fiber laser engravers are permanent and resistant to wear and tear. Unlike traditional engraving or printing methods, which may fade or degrade over time, fiber laser markings remain intact, ensuring that branding, serial numbers, and logos are always legible. This durability adds significant value to products, particularly in industries where traceability is essential. -

Speed and Efficiency

Fiber laser engravers operate at rapid speeds, making them ideal for high-volume production. The quick marking capabilities enable businesses to fulfill orders efficiently, reducing lead times and increasing overall productivity. This efficiency is particularly beneficial in competitive markets where time is of the essence. -

Low Operating Costs

With minimal maintenance requirements and a long lifespan—often exceeding 30 years—fiber laser engravers prove to be a cost-effective solution for businesses. Their energy-efficient design means lower operational costs compared to other laser technologies, allowing companies to maximize their investment.

Applications of Fiber Laser Engravers

Fiber laser engravers find applications across various industries, showcasing their versatility and effectiveness:

- Manufacturing: Used for marking parts with serial numbers, barcodes, and logos for traceability and quality control.

- Electronics: Ideal for marking PCBs and components with identification codes, aiding in inventory management.

- Medical Devices: Engraving surgical instruments with unique identifiers for sterilization tracking.

- Jewelry: Perfect for engraving intricate designs on precious metals, enhancing the aesthetic appeal of products.

- Aerospace: Engraving part numbers and QR codes on aircraft components for compliance and maintenance purposes.

Tips for Choosing the Right Fiber Laser Engraver

When investing in a fiber laser engraver, consider the following factors to ensure you select the best machine for your needs:

-

Material Compatibility: Ensure the engraver can handle the specific materials you plan to work with, whether metals, plastics, or ceramics.

-

Power and Speed: Look for a machine with adjustable power settings and fast marking speeds to suit your production requirements.

-

User-Friendly Interface: A machine with an intuitive interface will reduce the learning curve and enhance productivity, especially for new users.

-

Support and Maintenance: Choose a manufacturer that provides reliable customer support and readily available replacement parts to minimize downtime.

-

Budget Considerations: While quality is essential, ensure you are getting good value for your investment. Compare features, price, and performance across different models.

Maximizing the Potential of Your Fiber Laser Engraver

To get the most out of your fiber laser engraver, consider these tips:

-

Regular Maintenance: Keep your machine clean and well-maintained to ensure optimal performance and longevity.

-

Experiment with Settings: Take the time to adjust power, speed, and focus settings to achieve various effects on different materials.

-

Utilize Software Features: Make full use of the engraving software to customize designs and streamline your workflow.

-

Train Your Team: Ensure your staff is trained in operating the machine efficiently, maximizing its capabilities.

-

Explore New Applications: Don’t hesitate to innovate and explore new applications for your fiber laser engraver to keep your offerings fresh and appealing.

Conclusion

Investing in a fiber laser engraver can significantly enhance your business's capabilities, providing high precision, versatility, and durability. Whether you're in manufacturing, electronics, medical devices, or jewelry, this technology offers endless possibilities for customization and branding. By choosing the right machine and maximizing its potential, you can elevate your products and stand out in a competitive market.

If you’re ready to transform your business and take advantage of the benefits that fiber laser engraving offers, consider integrating this cutting-edge technology into your operations. The future of precision marking and engraving is here—embrace it with a fiber laser engraver.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness