How Do Innovations in API Pumps Impact Performance?

https://www.lg-pumps.com/

API pumps are essential for precise fluid transport in demanding industries like oil and gas, power generation, and chemical manufacturing. Built to API standards, these pumps offer reliable performance. Innovations in materials, energy efficiency, and monitoring systems enhance longevity, reduce operating costs, and improve environmental impact. Discover how these advancements are transforming fluid management.

What Are API Pumps and Their Role in Industry?

In sectors of industry API pumps are essential for moving fluids in specific situations and follow the guidelines set by the American Petroleum Institute to guarantee their effectiveness and dependability.

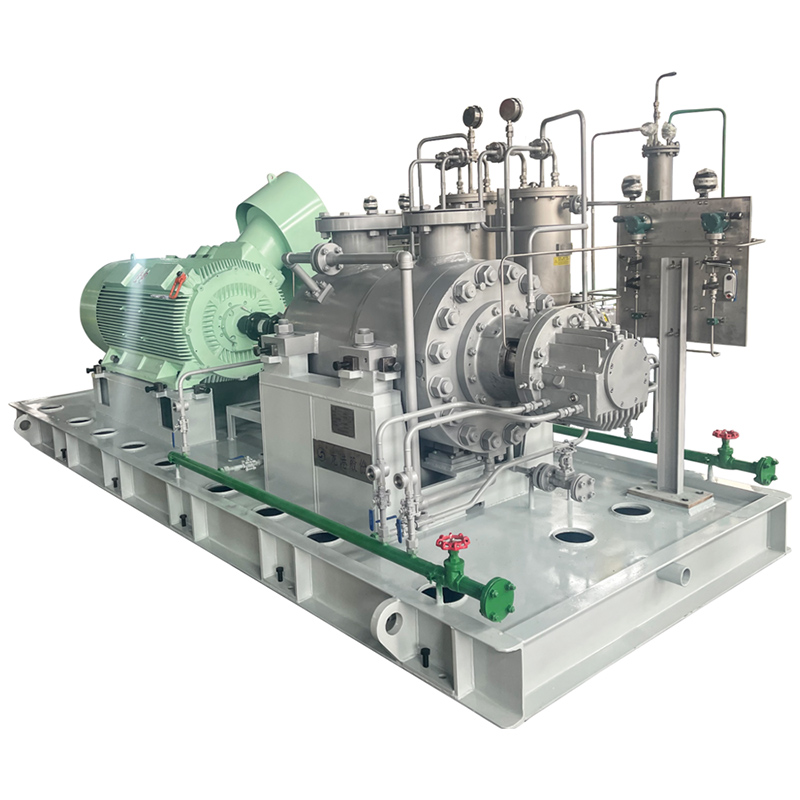

Overview of API Pumps

API pumps are designed for petroleum refining and natural gas processing, handling high temperatures, pressures, and corrosive substances. The LZA11th series single stage cantilever pump complies with API610 (IS013709) OH1 standards, meeting industry norms like API610 11# for centrifugal pumps and API682 4# for pump shaft seal systems.

Key Applications of API Pumps

Pumps are used in industries for operations like atmospheric and vacuum refineries, catalytic cracking, and coking, and sectors such as coal chemical, power plants, chemical fiber production, and environmental protection. Designed for transporting vaporized and low-temperature substances, they are ideal for ammonia, ethylene product pumping, and transferring liquefied gases.

Importance of API Standards in Pump Design

It is crucial to have API standards in place to guarantee that pumps can handle the conditions they work in effectively and safely. These standards cover details, like design specifications and material needs to ensure performance. The shaft is built as a shaft structure that meets the stiffness index criteria outlined in API610 11 Appendix K enhancing both safety and stability.

How Have Technological Advancements Enhanced API Pump Efficiency?

The materials and design enhancements in API pumps have greatly boosted their efficiency thanks to the advancements in technology.

Corrosion Resistance

The components utilized in API pumps have advanced to offer improved protection against corrosion—a factor in preserving the pump's integrity while managing corrosive substances effectively. To ensure a seal, between the pump body and cover when transporting high temperatures and dangerous media, high-reliability metal spiral wound gaskets are employed.

Durability and Longevity

Enhancing durability is also vital. This is achieved through advancements in materials used for pump operations over extended periods without issues due to the use of strong materials and lubrication of rolling bearings with thin oil to prolong their service life and minimize wear and tear.

Improved Hydraulics

Innovations in hydraulic design have led to more efficient fluid handling capabilities. The pump body adopts a volute structure design, which balances radial forces effectively.

Energy Efficiency Features

Energy efficiency has taken stage in the design of pumps by lowering operating expenses while still delivering top notch performance levels.This is achieved through the implementation of a volute structure that minimizes radial forces to lessen shaft loads and prolong the lifespan of bearings.

In What Ways Do Innovations Affect the Reliability of API Pumps?

The dependability of pump performance is crucial. Has improved with advancements in monitoring features and operational consistency.

Enhanced Monitoring and Diagnostic Technologies

Real-time Monitoring Systems

Contemporary API pumps come equipped with monitoring systems that offer ongoing updates on the pumps performance enabling prompt identification of any irregularities or possible malfunctions.

Predictive Maintenance Tools

By using maintenance tools you can take proactive measures to manage pump systems by predicting and addressing potential problems before they cause any downtime issues.The setup of auxiliary and monitoring systems is essential for maintaining the safe operation of these systems.

Impact on Operational Stability

Operational stability is improved through advanced engineering solutions that address common challenges faced during pump operation. Most of the axial forces are balanced using a combination of sealing rings and balance holes, which contributes to stable performance even under challenging conditions.

Industries can enhance their efficiency and reliability with API pumps by utilizing advancements in materials and design along with monitoring technologies and maintenance strategies.

How Do Advanced Manufacturing Techniques Influence API Pump Performance?

The integration of advanced manufacturing techniques has revolutionized the production and performance of API pumps. These methods ensure precision, improve efficiency and enhance the overall quality of the pumps.

Precision Manufacturing Processes

Precision in manufacturing processes is crucial for API pumps to meet stringent industry standards. By employing state-of-the-art technologies, manufacturers can achieve higher accuracy in pump components, leading to improved performance. The bare shaft structure of the pump as mentioned in the knowledge base, exemplifies how precise engineering meets specific requirements set by standards like API610 11</span> Appendix K. This precision enhances safety and stability, ensuring that the pumps operate efficiently under demanding conditions.

Benefits of 3D Printing in Pump Components

The use of 3D printing has become a game changer in producing pump parts for manufacturers by simplifying prototyping and customization processes that were once challenging using techniques. It speeds up development. Cuts down material waste while saving costs. The capability to craft designs meets the demand for reliable metal spiral wound gaskets crucial for sealing hazardous media in high temperatures.

What is the Environmental Impact of Modern API Pump Innovations?

The environmental effects of advancements in API pump technology are substantial because these innovations strive to lower energy usage and support environmentally friendly initiatives.

Reduction in Energy Consumption

Energy efficiency is a key focus in the design of contemporary API pumps. By optimizing hydraulic designs and incorporating energy-saving features, these pumps can operate more efficiently, reducing their carbon footprint. The double volute structure used in some pump models helps decrease radial forces and extend bearing life, which in turn lowers energy consumption during operation.

Eco-friendly Material Usage

The trend of incorporating eco-materials in the production of pumps indicates a greater dedication to environmental responsibility among companies nowadays. Manufacturers are now favorably choosing materials that ensure durability while also upholding values. Moreover employing oil lubrication for rolling bearings not only prolongs their lifespan but also plays a part in lessening environmental harm through the reduction of lubricant wastage.

How Do These Innovations Translate to Cost Savings for Industries?

Innovations in API pump technology lead to substantial cost savings for industries through reduced maintenance expenses and extended operational lifespan.

Lower Maintenance Costs

Advanced monitoring technologies and predictive maintenance tools have transformed how industries manage pump systems. By enabling real-time data analysis and early detection of potential issues, these innovations help prevent costly downtime and repairs. The inclusion of various auxiliary and monitoring systems ensures safe operation and reduces the frequency of maintenance interventions.

Increased Operational Lifespan

The durability of API pumps is improved by design elements and top notch materials that can withstand tough working environments effectively. By incorporating wear resistant parts such as bearings lubricated with thin oil greatly helps in prolonging the pumps lifespan. This ultimately leads to industries enjoying longer equipment life spans. Decreased requirements for frequent replacements and related expenses.

The progress in technology within manufacturing processes and design engineering not enhances performance but also provides economic benefits while promoting environmental sustainability efforts in different sectors.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness