Distributed Control Systems Market in Manufacturing: Automation Trends

Introduction

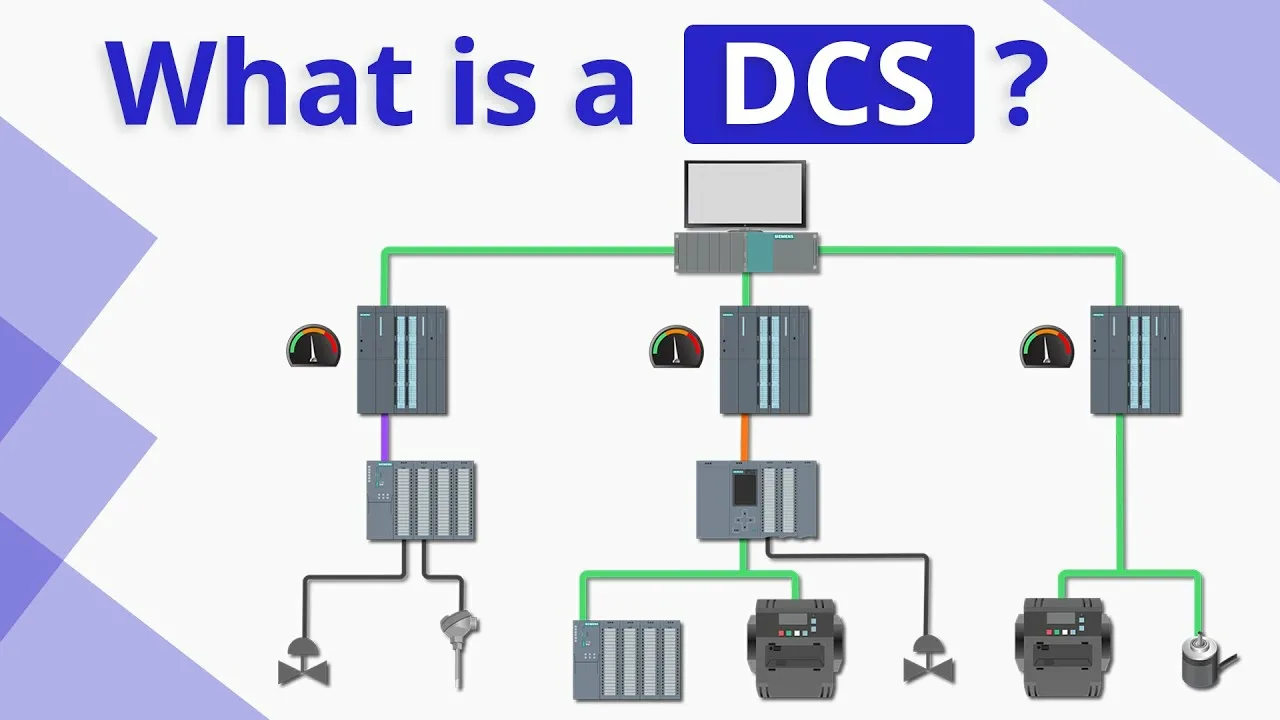

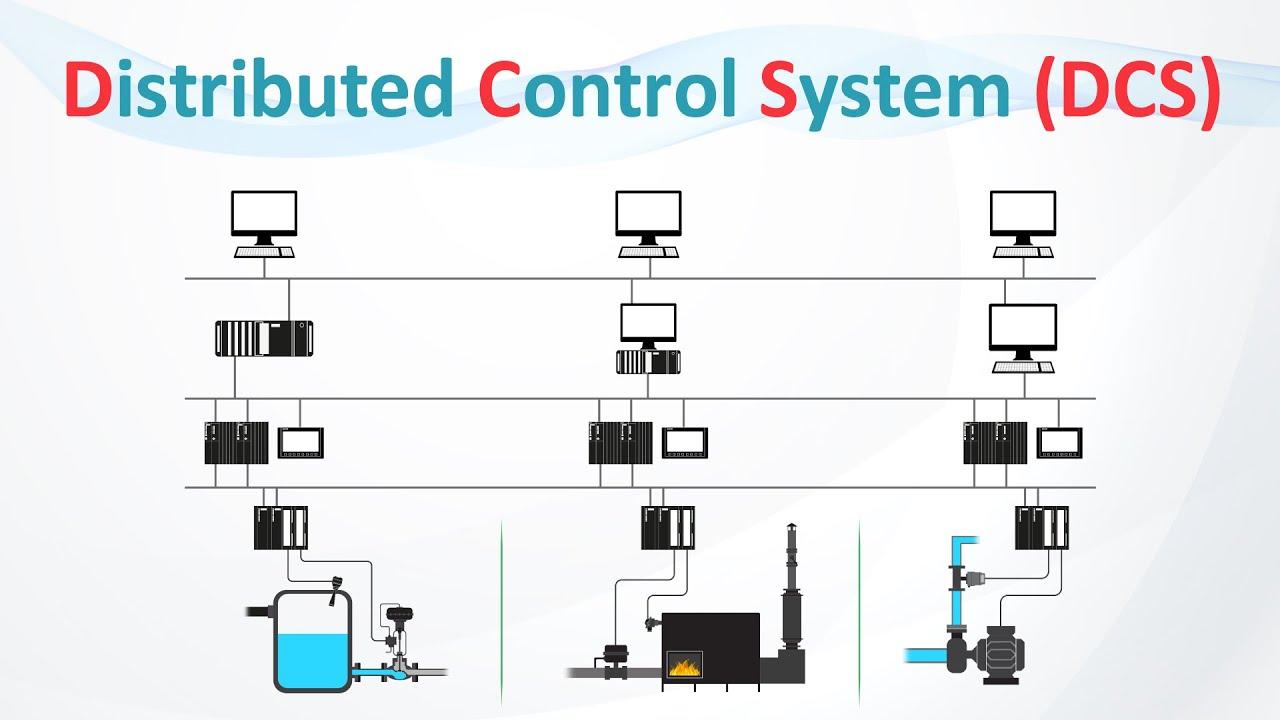

The Distributed Control Systems market in manufacturing is evolving rapidly due to increasing adoption of automation, Industry 4.0 technologies, and the demand for operational efficiency. As manufacturing processes become more complex and data-driven, DCS plays a critical role in optimizing production, ensuring quality control, and enhancing safety. This article explores key automation trends shaping the DCS market in manufacturing.

Key Trends in the Manufacturing DCS Market

1. Industry 4.0 and Smart Manufacturing

The rise of Industry 4.0 has transformed manufacturing operations through the use of IoT, AI, big data, and cloud computing. DCS solutions are integrating with smart sensors and advanced analytics to enable real-time monitoring, predictive maintenance, and seamless automation across production lines.

2. Adoption of Robotics and AI-driven Automation

Manufacturers are increasingly deploying robotic process automation (RPA) and AI-driven control systems to enhance efficiency and reduce human intervention. DCS platforms are evolving to coordinate robotic assembly lines, adaptive manufacturing processes, and autonomous quality inspections.

3. Cloud-Based and Remote Monitoring Solutions

Cloud technology is revolutionizing manufacturing by enabling remote monitoring, centralized data management, and cloud-based DCS solutions. These advancements allow manufacturers to manage multiple production facilities from a single interface, improving operational agility and cost savings.

4. Cybersecurity and Secure Automation

With increased connectivity in smart factories, cybersecurity threats pose a significant risk to automated control systems. Modern DCS solutions incorporate advanced encryption, AI-based threat detection, and multi-layered access control to safeguard manufacturing operations from cyberattacks.

5. Energy Efficiency and Sustainable Manufacturing

Manufacturers are under pressure to reduce their carbon footprint and optimize energy consumption. DCS plays a crucial role in energy-efficient production by automating processes such as power distribution, waste reduction, and resource optimization, aligning with global sustainability goals.

Key Opportunities in the Market

1. Modernization of Legacy Manufacturing Facilities

Many factories still rely on outdated control systems. Upgrading to smart, data-driven DCS solutions presents a significant growth opportunity as manufacturers seek to improve efficiency, reduce downtime, and enhance production flexibility.

2. Expansion of Industrial Automation in Emerging Markets

Countries in Asia-Pacific, Latin America, and the Middle East are witnessing rapid industrialization, driving demand for advanced DCS solutions. Investment in automated manufacturing and smart factories is creating new market opportunities.

3. Integration of Digital Twins and Simulation Technologies

The adoption of digital twin technology is gaining momentum in manufacturing. By integrating DCS with simulation tools, manufacturers can model, test, and optimize production processes before implementation, reducing costs and improving efficiency.

4. Demand for Customizable and Scalable DCS Solutions

Manufacturers require modular and scalable DCS platforms that can adapt to changing production demands. Vendors offering flexible, industry-specific DCS solutions will have a competitive advantage in the evolving market.

5. Advancements in 5G and Edge Computing

The integration of 5G networks and edge computing is enhancing real-time data processing and communication between machines. DCS solutions leveraging these technologies will improve responsiveness, precision, and overall manufacturing productivity.

Conclusion

The DCS market in manufacturing is set for substantial growth, driven by automation, digital transformation, and sustainability initiatives. As manufacturers embrace Industry 4.0, smart factories, and AI-driven production, the demand for advanced DCS solutions will continue to rise. Companies investing in cloud-enabled, cybersecurity-focused, and scalable DCS platforms will be well-positioned to lead the future of industrial automation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness