Metal Powder Market Size, Share, and Regional Insights (2024-2030)

The Metal Powder Market: A Comprehensive Analysis

The Metal Powder Market Size is a dynamic and rapidly evolving sector, playing a pivotal role in industries ranging from automotive to aerospace, healthcare, and beyond. With advancements in manufacturing technologies and the increasing demand for lightweight, durable materials, metal powders have become indispensable. This article delves into the market's definition, growth drivers, segmentation, country-level analysis, and competitive landscape, offering a fresh perspective on this fascinating industry.

Click Here For Free Sample Report Link:https://www.maximizemarketresearch.com/request-sample/42246/

1. Market Estimation & Definition

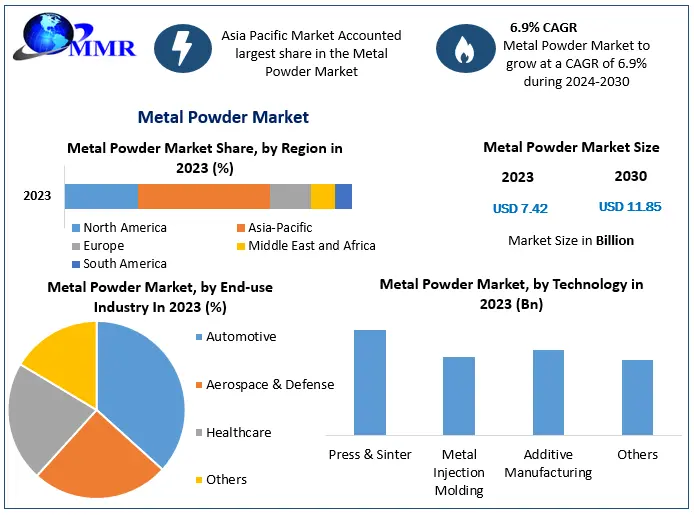

Metal powders are finely divided particles of metals or alloys, used in various applications such as additive manufacturing (3D printing), powder metallurgy, and surface coating. The global metal powder market was valued at USD 8.5 billion in 2022 and is projected to grow at a CAGR of 6.5% from 2023 to 2029, reaching nearly USD 13.2 billion by the end of the forecast period.

The market's growth is fueled by the increasing adoption of metal powders in industries like automotive, aerospace, and healthcare, where precision, durability, and lightweight materials are critical. Metal powders are also gaining traction in emerging technologies such as 3D printing, which is revolutionizing manufacturing processes.

2. Market Growth Drivers & Opportunities

Key Drivers

-

Rising Demand for Additive Manufacturing:

3D printing has emerged as a game-changer, enabling the production of complex, customized components with minimal waste. Metal powders, such as titanium, aluminum, and nickel alloys, are widely used in this sector, driving market growth. -

Automotive Industry's Shift Toward Lightweight Materials:

With the automotive industry focusing on fuel efficiency and reducing carbon emissions, metal powders are increasingly used to manufacture lightweight, high-strength components. -

Growing Aerospace Sector:

The aerospace industry demands materials that can withstand extreme conditions while being lightweight. Metal powders, especially titanium and nickel-based alloys, are ideal for this purpose. -

Advancements in Powder Metallurgy:

Powder metallurgy allows for the production of near-net-shape components, reducing material waste and manufacturing costs. This technology is gaining popularity in industries like healthcare and electronics.

Emerging Opportunities

-

Healthcare Applications: Metal powders are used to manufacture medical implants, prosthetics, and dental devices. The growing aging population and increasing healthcare expenditure present significant opportunities.

-

Renewable Energy Sector: Metal powders are used in the production of wind turbines and solar panels, aligning with the global shift toward renewable energy.

-

Research & Development: Continuous innovation in metal powder production techniques, such as atomization and electrolysis, is opening new avenues for market growth.

3. Segmentation Analysis

The metal powder market is segmented based on type, production method, application, and region.

By Type

-

Ferrous Metals:

-

Iron and steel powders dominate this segment due to their widespread use in automotive and industrial applications.

-

-

Non-Ferrous Metals:

-

Aluminum, titanium, and nickel powders are gaining traction in aerospace, healthcare, and additive manufacturing.

-

By Production Method

-

Atomization:

-

The most common method, producing spherical powders ideal for 3D printing and powder metallurgy.

-

-

Electrolysis:

-

Used for producing high-purity metal powders, especially copper and iron.

-

-

Chemical Reduction:

-

Suitable for producing tungsten and molybdenum powders.

-

By Application

-

Additive Manufacturing:

-

The fastest-growing segment, driven by the adoption of 3D printing in various industries.

-

-

Powder Metallurgy:

-

Widely used in automotive and industrial applications for producing complex components.

-

-

Surface Coating:

-

Metal powders are used for thermal spray coatings to enhance durability and corrosion resistance.

-

By Region

-

North America:

-

Leading the market due to the presence of major aerospace and automotive manufacturers.

-

-

Europe:

-

Driven by the growing demand for lightweight materials in the automotive and aerospace sectors.

-

-

Asia-Pacific:

-

The fastest-growing region, fueled by industrialization and the expansion of the automotive and electronics industries.

-

More Insights Of Full Report In Details:https://www.maximizemarketresearch.com/market-report/metal-powder-market/42246/

4. Country-Level Analysis

United States

The U.S. is a major player in the metal powder market, driven by its robust aerospace and automotive industries. The country is also a hub for additive manufacturing, with significant investments in 3D printing technologies. The presence of key market players like Höganäs AB and GKN Powder Metallurgy further strengthens the market.

Germany

Germany is a leading market in Europe, known for its advanced manufacturing capabilities. The country's automotive industry, home to giants like BMW and Volkswagen, is a major consumer of metal powders. Additionally, Germany's focus on renewable energy and healthcare is creating new opportunities for market growth.

5. Competitive Analysis

The metal powder market is highly competitive, with key players focusing on innovation, mergers, and acquisitions to strengthen their market position. Some of the prominent players include:

-

Höganäs AB:

-

A global leader in metal powder production, known for its high-quality iron and steel powders.

-

-

GKN Powder Metallurgy:

-

Specializes in powder metallurgy components for the automotive and aerospace industries.

-

-

Sandvik AB:

-

Offers a wide range of metal powders, including titanium and nickel alloys, for additive manufacturing.

-

-

Carpenter Technology Corporation:

-

Focuses on advanced materials, including specialty metal powders for aerospace and healthcare applications.

-

Strategies Adopted by Key Players

-

Product Innovation: Companies are investing in R&D to develop advanced metal powders with enhanced properties.

-

Strategic Partnerships: Collaborations with end-users and technology providers are helping companies expand their market reach.

-

Geographic Expansion: Key players are establishing production facilities in emerging markets to capitalize on growing demand.

6. Conclusion

The metal powder market is poised for significant growth, driven by the increasing adoption of additive manufacturing, the automotive industry's shift toward lightweight materials, and the growing demand from the aerospace and healthcare sectors. With advancements in production techniques and the emergence of new applications, the market offers immense opportunities for stakeholders.

However, challenges such as high production costs and the need for specialized equipment may hinder market growth. To overcome these challenges, companies must focus on innovation, strategic partnerships, and geographic expansion.

As the world moves toward a more sustainable and technologically advanced future, metal powders will continue to play a crucial role in shaping industries and driving innovation. Whether it's 3D-printed aerospace components or lightweight automotive parts, the possibilities are endless, and the metal powder market is at the forefront of this transformation.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness