Key Features of an Automatic Changing Width Panel Machine You Should Know

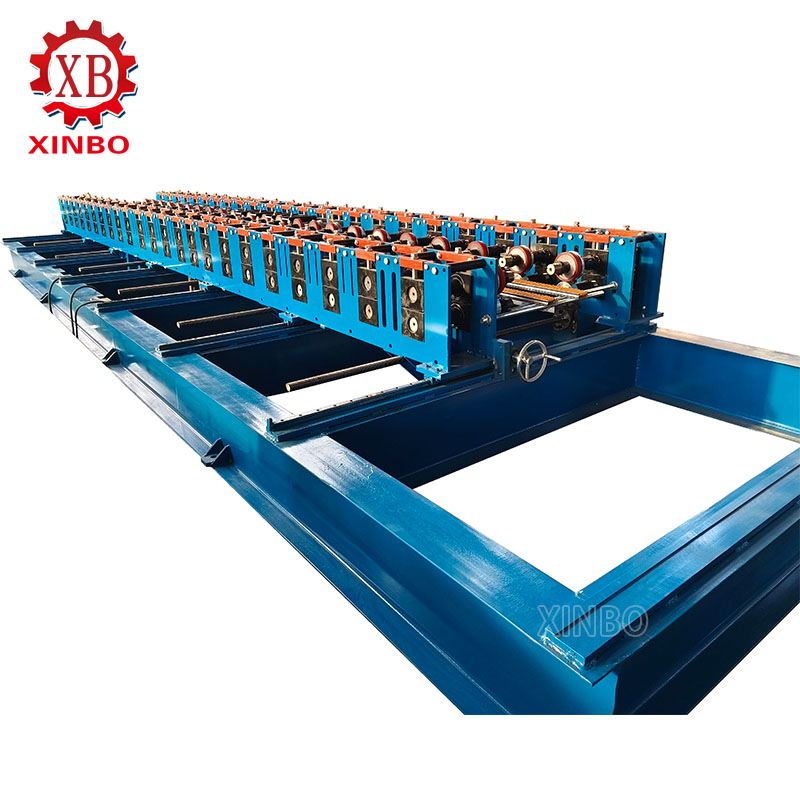

Overview of Automatic Changing Width Panel Machines

Definition and Purpose

Automatic Changing Width Panel Machines are tools created to automatically modify panel widths in the manufacturing process. Production lines need panel sizes for flexibility and efficiency. These machines streamline the width adjustment process by removing the need, for intervention resulting in cost savings and error reduction.

Importance in Modern Manufacturing

In today's manufacturing sector, it's vital to precisely tweak panel widths. Sectors like furniture making, automobile manufacture, ng, and construction heavily depend on these devices to fulfill the need for tailor-made goods. The accuracy provided by Automated Panel Width Adjustment Machines enables manufacturers to uphold top-notch standards while swiftly adjusting to requirements. This flexibility boosts efficiency. Gives a competitive advantage in a market where personalized products are, in high demand.

Evolution of Panel Machines

Panel machines have evolved greatly over time from being operated to becoming fully automated systems that seamlessly integrate with other manufacturing processes today. The shift towards automation was fueled by the desire for improved efficiency and precision, in manufacturing environments.

Core Components of the Machine

Main Frame and Structure

Material and Durability

The primary structure of an Automatic Width Panel Changing Machine is usually made from materials like steel and aluminum alloys that can endure the demands of constant use in industrial environments. These materials play a role, in enhancing the machine's durability and resilience to regular wear and tear for for long-lasting and dependable performance.

Design Specifications

The design requirements are essential, for the operation of these machines and must consider different panel sizes while ensuring stability during use. The precise engineering work guarantees that the parts fit properly and enables easy width adjustments without harming the panels or machine parts.

Control System

Programmable Logic Controllers (PLCs)

The control system of an Automatic Width adjusting Panel Machine revolves around Logic Controllers (PLCs). These controllers carry out algorithms to oversee the machine's functions by receiving sensor input data and sending instructions to actuators that modify panel widths based on predetermined settings.

User Interface Features

The user interface is created for user convenience to effortlessly enter specifications and make adjustments swiftly while focusing smoothly and efficiently towards achieving production goals using interfaces and easy-to-use software for setting up and monitoring machine operations.

Operational Mechanism

Width Adjustment Process

Sensors and Detection Systems

Panel dimensions are accurately detected by sensors that play a role in ensuring precise width adjustments are made effectively in advanced systems employing laser or optical sensors, for measurement purposes.

Adjustment Algorithms

Fine-tuning algorithms play a role in ensuring accurate adjustments to the width of panels are made effectively. These algorithms analyze data from sensors. Decide the best configurations, for actuators that adjust the physical dimensions of panels. Through the improvement of these computations, machines can attain great precision even when working with intricate or nonuniform panel shapes.

Automation Capabilities

Integration with Other Systems

Automation capabilities go beyond adjusting widths – these machines can also work alongside other systems in a production line setting by syncing up with conveyors or robotic arms to smoothly move panels, between various stages of the manufacturing process.

Efficiency Enhancements

Improving efficiency in manufacturing can be achieved by automating processes to reduce cycle times and minimize downtime between production runs allowing automated systems to adjust quickly to product specifications without stopping operations completely leading to notable productivity improvements, in manufacturing facilities.

Technological Advancements in Panel Machines

Smart Technology Integration

IoT Connectivity

The integration of smart technology has revolutionized Automatic Changing Width Panel Machines by enabling IoT connectivity. This allows machines to communicate with other devices within a networked environment—facilitating remote monitoring, diagnostics, and control via cloud-based platforms.

Real-time Monitoring Features

Operators can receive feedback on machine performance metrics like speed and accuracy levels through real-time monitoring features available, to them and are empowered to make well-informed decisions that improve operational efficiency even more.

Energy Efficiency Improvements

Enhancing energy efficiency has become increasingly important due to growing awareness and higher energy expenses worldwide. This has led manufacturers to prioritize practices in their machinery investments, such as the integration of energy-saving technologies, in Automatic Changing Width Panel Machines. These advancements aim to decrease power usage without majorly impacting output quality or speed levels.

Applications in Various Industries

Furniture Manufacturing

Automatic Panel Resizing Machines have transformed the furniture-making sector by making it possible to create panels of customized sizes with efficiency. These machines enable manufacturers to quickly modify panel widths according to design needs making it easier to craft unique furniture items. The. The rapidity of these machines aids inntting down production times and enhancing productivity as a whole. Moreover, they play a role, in reducing waste by maximizing the use of resources supporting-friendly manufacturing methods.

Automotive Industry Applications

Within the sector, Automatic Changing Width Panel Machines are vital for creating different parts that need precise measurements and top-notch finishes. These machines are essential in crafting paelsdashboardssard, DS, and other key elements that require specific standards for a perfect fit and functionality The capability to automatically adjust widths guarantees uniformity, across manufacturing cycles and enables the dependability and safety of car components. Moreover,r such machines contribute to theindustry'sffortbyincorporatinge materials by accommodating various panel variants without sacrificing efficiency.

Construction Sector Usage

The field of construction greatly advantages from utilizing Automatic Changing Width Panel Machines for crafting building materials like wall panels and roofing components for instance flooring systems. These machines allow for tailoring panel dimensions to match architectural layouts and project needs effectively. By automating the resizing process; construction firms can attain heightened accuracy, in panel production leading to enhanced strength and visual attractiveness. This feature holds importance in extensive projects where consistency and excellence hold utmost importance.

Benefits of Using Automatic Changing Width Panel Machines

Cost Efficiency

One major benefit of using Automatic Changing Width Panel Machines is their ability to increase cost efficiency in manufacturing processes. By automating width adjustments these machines help cut down on labor expenses linked to work. They also improve material usage by reducing waste through cutting and sizing procedures. The decrease, in production time also leads to reduced costs allowing manufacturers to provide competitive prices and keep profits stable.

Precision and Accuracy

The precision and accuracy offered by Automatic Variable Width Panel Machines are unmatched in their capabilities. These machines utilize sensors and control mechanisms to guarantee that each panel adheres precisely to the required specifications without any deviations. This high degree of precision is vital, in sectors where even slight variations can result in product defects or operational problems. By upholding quality standards companies can establish credibility with their clientele and cut down expenses linked to reworking or product returns.

Flexibility and Versatility

Automatic Adjustable Panel Machines provide flexibility and adaptability for manufacturers to respond swiftly to evolving market needs or customer choices. They are capable of accommodating panel sizes and materials for a variety of uses across different industries . Their seamless integration with manufacturing systems boosts overall production agility by allowing quick transitions between different product lines or setups, with minimal downtime.

Future Trends in Automatic Changing Width Panel Machines

Emerging Technologies

The landscape of Automatic Width Panel Machines is on the verge of a significant shift thanks to the rise of cutting-edge technologies like intelligence (AI) and machine learning (ML). These innovations have the potential to boost machine functionalities by facilitating maintenance tasks and automatically fine-tuning operational settings using insights from past data analysis processes in manufacturing settings to enhance decision-making procedures significantly. As AI progresses further these machines are expected to operate with autonomy reducing the need, for extensive human supervision while consistently delivering top-notch performance results.

Potential Innovations

In the field of Automatic Changing Width Panel Machines, there are possibilities for progress. These may involve enhancements in how materials are handled enabling smooth shifts between various panel types without the need for manual adjustments. Additionally, there is potential, for boosting energy efficiency through intelligent power management systems. Such systems could lower energy consumption during times ononbusyy hours providing benefits such as a reduced environmental footprint and cost savings at the same time. Innovation can also focus on improving user interfaces to streamline setup processes making it easier for operators of all skill levels to achieve their desired results quickly and efficiently. This will lead to increased adoption, across sectors aiming to enhance competitiveness through advanced technology investments.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness