Exploring the Benefits of an Automatic Changing Width Panel Machine

Understanding the Functionality of Automatic Changing Width Panel Machines

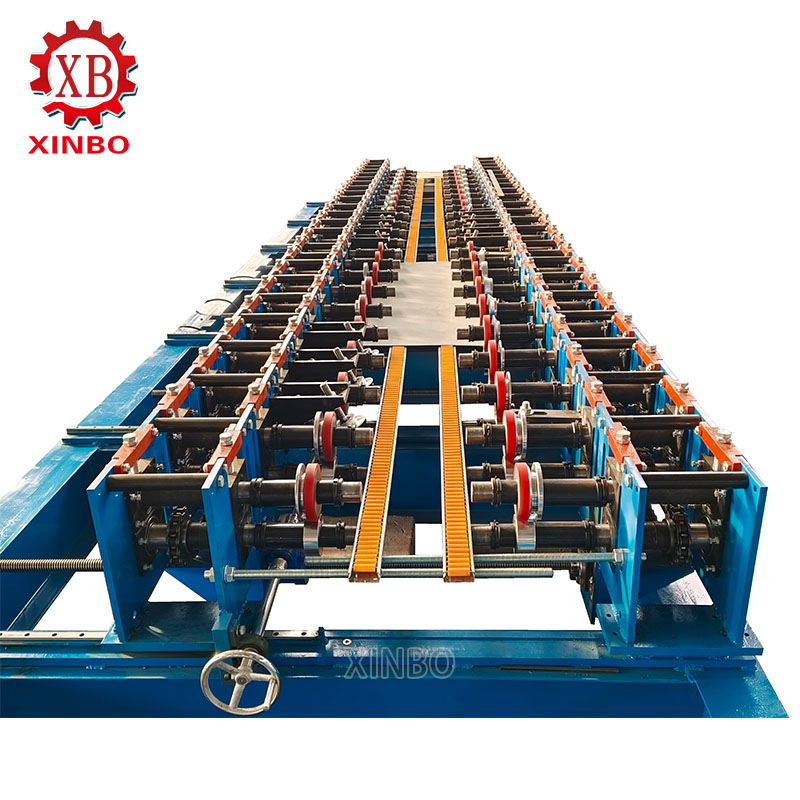

Automatic width adjustable panel machines represent a marvel of contemporary engineering that aims to simplify the task of altering panel widths with accuracy and effectiveness. These machines play a role in sectors that demand quick adjustments, in panel sizes and provide smooth incorporation into current operational processes.

Key Components and Mechanisms

In the core of an Automatic Variable Width Panel Machine lie its parts and mechanisms that play a vital role in its operation and efficiency. Typically comprising clamps to secure panels firmly in place and servo motors for precise movement and width adjustment of panels. Moreover, control systems powered by software work harmoniously to coordinate these components ensuring seamless operation and accurate measurements. The integration of hardware and software is essential, for upholding the machine's dependability and optimal performance.

Operational Workflow and Process Integration

The machine operational flow is optimized for efficiency purposes at the start panels are inserted into the machine for which sensors measure their dimensions next up the control system crunches the numbers to figure out what tweaks are needed to get the right width servo motors swiftly make these adjustments with guidance from sensors real-time updates ensuring precision this smooth process enables fast adjustment, to different panel sizes without needing manual interference cutting downtime by a substantial amount.

Technological Advancements in Design

In times Automatic Changing Width Panel Machines have seen significant improvements in their functionality due to technological advancements. Newer models now incorporate innovations, like AI algorithms and IoT connectivity which help in optimizing operational settings for various materials to ensure top-notch performance across a range of applications. Moreover, the integration of connectivity enables remote monitoring and diagnostics making way for predictive maintenance practices and reducing unforeseen breakdown instances.

Advantages of Using Automatic Changing Width Panel Machines

The use of Automatic Width Adjustable Panel Machines brings benefits that enhance operational efficiency in different sectors.

Enhanced Efficiency and Productivity

One major advantage is the improved efficiency and productivity it brings about when machines handle the process of adjusting width automatically relying on manual recalibration tasks to speed up production cycles. This automated process not only cuts down on labor expenses but also reduces the chances of human error occurring, resulting in a more consistent level of product quality being maintained over time.Cost-effectivenessnd Resource Optimization

Another key benefit is cost efficiency as these machines are precise and minimize material waste by making cuts consistently leading to savings in the long run due to reduced raw material usage, in production processes.

Improved Precision and Customization Capabilities

Automatic Changing Width Panel Machines also provide accuracy and customization features enabling manufacturers to meet specific customer needs efficiently without the need for extensive retooling or setup alterations. This adaptability aligns with the growing trend towards mass customization strategies, in today's market demands.

Applications in Various Industries

The flexibility of Automated Width Adjusting Panel Devices makes them highly beneficial, in sectors.

Utilization in the Furniture Manufacturing Sector

In the realm of furniture products, these machines are crucial as they allow for customization to cater to furniture styles and designs, with ease and efficiency Manufacturers can quickly adjust panel sizes to meet specific design requirements or customer preferences without compromising on speed or quality of production.

Customization for Different Furniture Designs

This feature enables various product ranges to be produced in a manufacturing plant supporting companies in providing custom solutions while keeping operations streamlined.

Implementation in Construction and Building Projects

During construction and building endeavors Automatic Changing Width Panel Machines play a role in meeting various architectural needs. They enable on-the-spot modifications to match building blueprints or changes made during the construction process.

Adaptability to Diverse Architectural Requirements

This flexibility guarantees that construction schedules are met without sacrificing the integrity of the design or the strength of the structure.

Role in Automotive and Aerospace Manufacturing

In the aerospace industry,y these machines play a crucial role in crafting precise components for vital, safety-critical purposes. Their capacity to work with shapes while maintaining tight tolerances guarantees that products adhere to strict industry requirements and enhance manufacturing efficiency.

The integration of Automatic Changing Width Panel Machines into various industrial processes underscores their importance as tools for enhancing productivity, reducing costs, and delivering superior quality products tailored to market demands.

Considerations for Implementation

Selecting the Right Machine for Specific Needs

Assessing Production Requirements

When setting up an Automatic Panel Machine with width capabilities it's important to start by carefully evaluating the production needs at hand. This includes grasping the quantity of panels to be handled the widths required and the pace at which tasks need to be completed. By considering these aspects it guarantees that the chosen machine fits well with production targets reducing any obstructions and optimizing efficiency.

Evaluating Technological Features

It's also crucial to assess the functionalities of the machines at hand – things like how precise their adjustments are and how easily they can be integrated into current systems; not to mention the level of automation they provide as well as any advanced features like AI powered optimization and IoT capabilities that should be considered in light of operational requirements to gauge their actual benefit, in enhancing production efficiency and flexibility when choosing a machine that delivers smooth integration and cutting edge technology.

Maintenance and Upkeep for Optimal Performance

Routine Checks and Servicing

Keeping Automatic Changing Width Panel Machines in condition requires regular maintenance to ensure peak performance levels are maintained consistently over time. It's important to have a routine checkup plan in place to examine parts like servo motors and control systems for any signs of damage or deterioration in quality. Taking care of these checks regularly helps avoid sudden breakdowns and prolongs the machine's overall lifespan. Creating a maintenance schedule that involves tasks like lubrication application and system calibrations along with software updates is crucial, for keeping the machine running without any hiccups.

Troubleshooting Common Issues

With routine upkeep in place at work sites or facilities maintenance problems can crop up unexpectedly that demand prompt action to rectify them posthasteIt'ss not uncommon to encounter difficulties such as sensors losing their alignment or glitches in the system impacting precision Establishing step-by-step plans for addressing these hiccups plays a pivotal role in promptly pinpointing and remedying them This approach goes a long way in ensuring that any disruptions to the normal flow of production are kept minimal Educating staff members, on the basics of tackling such issues equips them with the know how to handle minor setbacks promptly before they spiral into major overhauls.

Future Trends in Automatic Changing Width Panel Machines

Innovations Driving Industry Growth

The upcoming developments in Automatic Changing Width Panel Machines are expected to see progress propelled by technological innovations. A notable trend is the incorporation of AI algorithms that can perform predictive analytics These algorithms can predict modifications based on data sets enabling enhanced accuracy and efficiency in live operations.FuFurthermorematerial science,e could result in machines that can handle a variety of materials with diverse characteristics.

Potential Developments in Machine Learning Integration

Machine learning has the potential to revolutionize Automatic Changing Width Panel Machines by making them systems that can learn from previous tasks to improve future operations on their own. This advancement could lead to setup times and improved customization options without needing manual intervention. Moreover, machine learning might help establish maintenance schedules that adapt to anticipate component failures before they happen to ensure production cycles.

As these trends progress further over time industries that make use of Automatic Changing Width Panel Machines are poised to reap the rewards of improved efficiencies, lower expenses,s, a anduperior product quality thanks, to technological innovations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness