Maximizing Performance with Advanced Crane Winch Systems

Understanding Crane Winch Systems

Crane winch systems play a role in ensuring the smooth and safe functioning of cranes in different sectors of industry. They form the core for lifting and relocating objects by offering essential power and precision. Having a grasp of the components and varieties of crane winch systems is key, for experts looking to optimize operational efficiency.

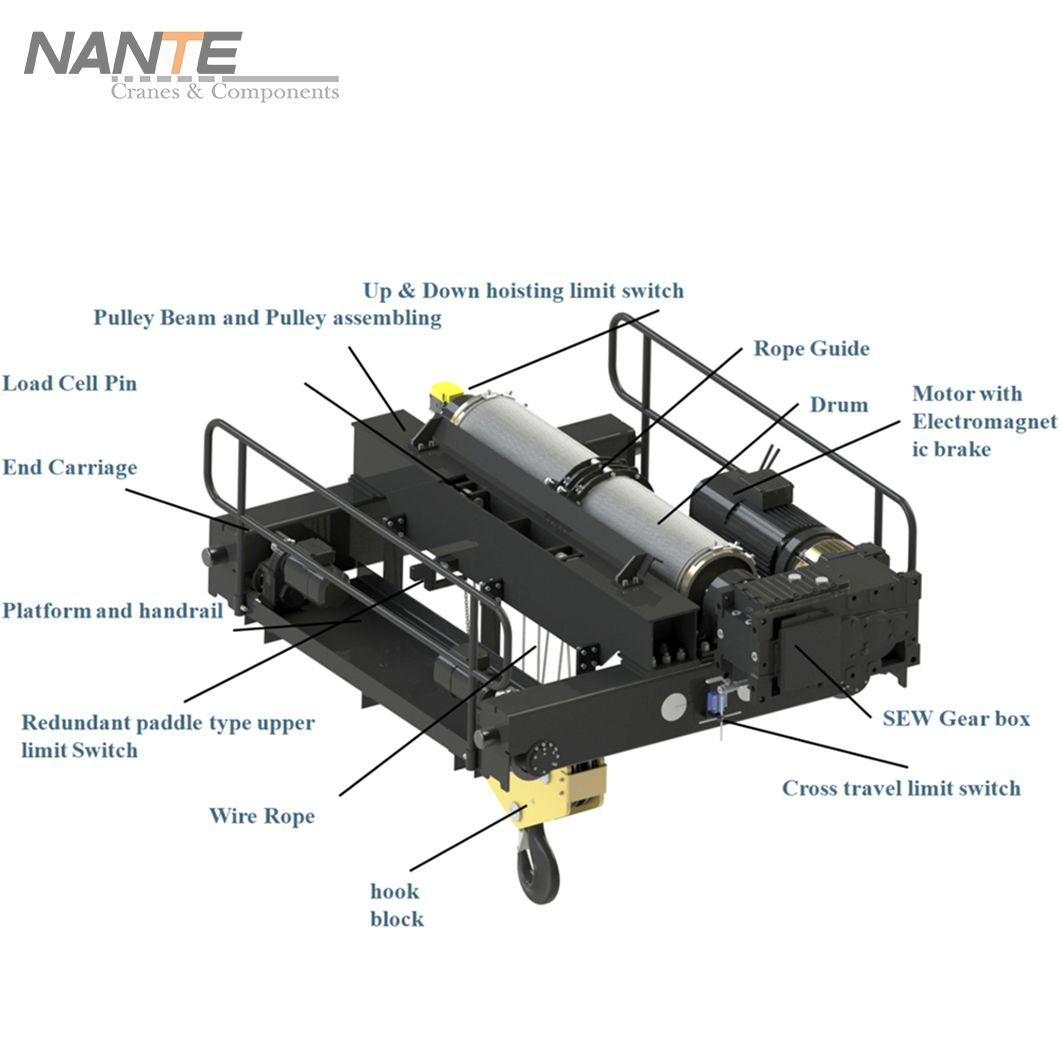

Components of a Crane Winch System

In a crane winch system, you have key parts that all work together to make sure everything runs smoothly; the drum is where the cable or rope, for lifting, is held and wound up; the motor gives the drum power to turn; and the gearbox helps control how fast and how much force is used to move heavy loads accurately.

The braking system plays a role in securing loads when stationary and the control system enables operators to oversee tasks with accuracy by integrating advanced functions, like variable speed controls and load monitoring abilities . These elements work together seamlessly to improve efficiency and safety standards.

Types of Crane Winch Systems

Different kinds of crane winch systems exist to fulfill operational needs, with electric winches being favored for their efficiency anuser-friendlyly nature in tasks that demand a steady power source. Hydraulic winches provide power and are recommended for heavy-duty tasks that involve high-weight capacities.

Air-powered winches function through the air and are favored in locations where electric or hydraulic setups could present safety concerns. Manual winches are not as prevalent in environments but offer a budget-friendly option for handling lighter loads or scenarios with restricted power sources. Choosing the kind of crane winch system is crucial, for maximizing performance to meet operational requirements adequately.

Enhancing Efficiency with Advanced Technologies

The incorporation of cutting-edge technologies, into crane winch systems has t, transformed their efficiency and effectiveness significantly. By adopting automation and intelligent technologies operators can attain levels of accuracy and productivity.

Automation in Crane Winch Operations

Automation plays a significant role in enhancing crane winch operations by reducing human intervention and minimizing errors. Automated systems can perform repetitive tasks with high accuracy, leading to increased productivity and reduced downtime. Features such as automatic load sensing adjust operations based on real-time data, ensuring optimal performance under varying conditions.

Furthermore, automated control systems allow remote operation, giving operators the ability to oversee cranes at once, from one central spot. This not only boosts productivity but also increases safety by keeping workers out of harm's way during operations.

Integration with IoT and Smart Technologies

The introduction of Internet of Things (IoT) technology in crane winch systems has brought about an era of connectivity and data-centric decision-making techniques. Sensors enabled by IoT offer monitoring of crucial factors, like load weight, temperature fluctuations, and motor efficiency. This gathered data allows for trend analysis, prediction of maintenance requirements, and operational optimization.

Smart technologies facilitate seamless communication between different components within a crane winch system, enabling adaptive responses to changing conditions. For instance, smart systems can automatically adjust speed or torque based on load characteristics or environmental factors. By leveraging IoT and smart technologies, operators can achieve higher levels of efficiency while minimizing risks associated with manual intervention.

Safety Features in Modern Crane Winch Systems

Safety is a priority in crane operations and has led to ongoing improvements in the safety components of modern crane winch systems Enhancements in these features not only guarantee adherence, to industry regulations but also safeguard both workers and machinery.

Overload Protection Mechanisms

In crane winch systems today having overload protection mechanisms is crucial to avoid accidents resulting from excessive loads. These safety features rely on sensors to constantly monitor the weight of the load and activate warnings or shutdown procedures if weight limits are surpassed. By averting situations of ooverloadloaded these systems safeguard both workers and machinery from harm or breakdown risks.

Besides having basic overload protection in place more advanced systems might also have dynamic load monitoring capabilities that can adjust operational settings depending on current conditions as they happen in real-time. This proactive strategy is, about ensuring a safe working environment and optimizing performance whenever there are different load requirements to meet.

Emergency Stop Functions

Emergency stop features play a role in ensuring safety by quickly stopping operations during emergencies or equipment failures. They are usually activated using located buttons or switches placed strategically at various points, across the crane site.

Today emergency stop systems might also offer wireless activation choices for better accessibility in urgent scenarios. This feature aids in quick response times, during emergencies to lessen the risk of accidents and reduce harm to individuals or machinery.

Ensuring strong safety measures are integrated into crane winch systems demonstrates a dedication, to establishing work environments and promoting smooth operations in various industrial settings.

Selecting the Right Crane Winch for Your Needs

Selecting the crane winch is a crucial choice that greatly affects how efficiently and safely operations run. Take a look, at load demands, environmental aspects, and the specific requirements of the application to make a well-informed decision.

Assessing Load Requirements and Capacity

The initial step, in choosing the crane winch is to grasp the load specifications thoroughly. This includes assessing the weight capacity that the winch will manage and verifying that the chosen system can meet these requirements. It's essential to take into account both moving loads and also be prepared for any unexpected shock loading situations that might arise during operations.

When choosing a crane winch it's important to select one with a capacity, then the expected maximum load to allow for safety margins and handle any unforeseen load increases effectively This strategy not only promotes safe operations but also helps in prolonging the equipment lifespan by avoiding overloading situations.

Moreover, professionals need to evaluate how long they engage in lifting tasks. Winches created for usage vary, from those meant for sporadic use so it is crucial to align the winch's duty cycle with the operational requirements.

Environmental Considerations

The environmental conditions have an impact on the choice of crane winch system needed for the job at hand. The performance and lifespan of the equipment can be affected by factors like temperature variations, humidity levels, and exposure, to substances.

In situations where there is a lot of moisture or exposure to salt in the air o corrosion resistant materials or coatings might be needed to avoid damage and decayed parts wear off quickly. Likewise, when winches are used in cold weather conditions they may need specific lubricants or heating mechanisms to work consistently well.

In places, like cities or neighborhoods where reducing noise is important electric winches are a good option because they tend to operate quietly compared to hydraulic or pneumatic ones.

Professionals also need to consider dangers found at the location, like explosive environments or poorly ventilated areas. When faced with situations it's crucial to choose a winch system that is specifically made for hazardous sites to adhere to safety rules and avoid mishaps.

Maintenance Practices for Optimal Performance

Ensuring that crane winch systems operate at their best for a time requires following strong maintenance routines diligently and consistently. Regular upkeep doesn't just boost effectiveness. Also cuts down on the time equipment is, out of service and brings down repair expenses.

Regular Inspection Protocols

Implementing inspection procedures is crucial for maintaining equipment effectively, with checks scheduled at set times according to the manufacturer's guidelines and usage trends.

Inspectors must carefully check all parts of the crane winch system. Such as drums, cables/ropes, motors, gearboxes, BRbrakes, and control systems. For any wear and tear faults, on to prevent pricey repairs and failures down the line.

Keeping a record of inspection results is crucial to monitor the state of equipment as time passes and pinpointing recurring problems that could signal issues is vital for maintenance planning purposes using modern digital tools for documentation can make this task easier and offer useful insights, for planning maintenance activities proactively.

Lubrication and Component Care

Ensuring the right lubrication is essential for keeping a crane winch system running smoothly and preventing wear on its moving parts, like gears and bearings by minimizing friction and guarding against corrosion.

Technicians need to follow the manufacturer's recommendations, on the kinds of lubricants to use and how often to apply them to ensure the best performance of the equipment they are working with automated lubrication systems are put in place so that lubrication is done regularly without needing manual input.

Taking care of more than just lubrication is essential for the functioning of various components in the long run. It's crucial to keep surfaces clean from dirt and debris that could affect performance or lead to damage over time. Additionally keeping connections secure and corrosion-free is key, to ensuring the control system works reliably.

Operators can enhance the performance of crane winches. Prolong the lifespan of equipment in various industrial settings by focusing on thorough maintenance routines, which involve routine inspections and careful component upkeep, such as ensuring proper lubrication is, in place.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness