The Mechanics Behind the Double Cone Blender's Efficiency

Understanding the Double Cone Blender Design

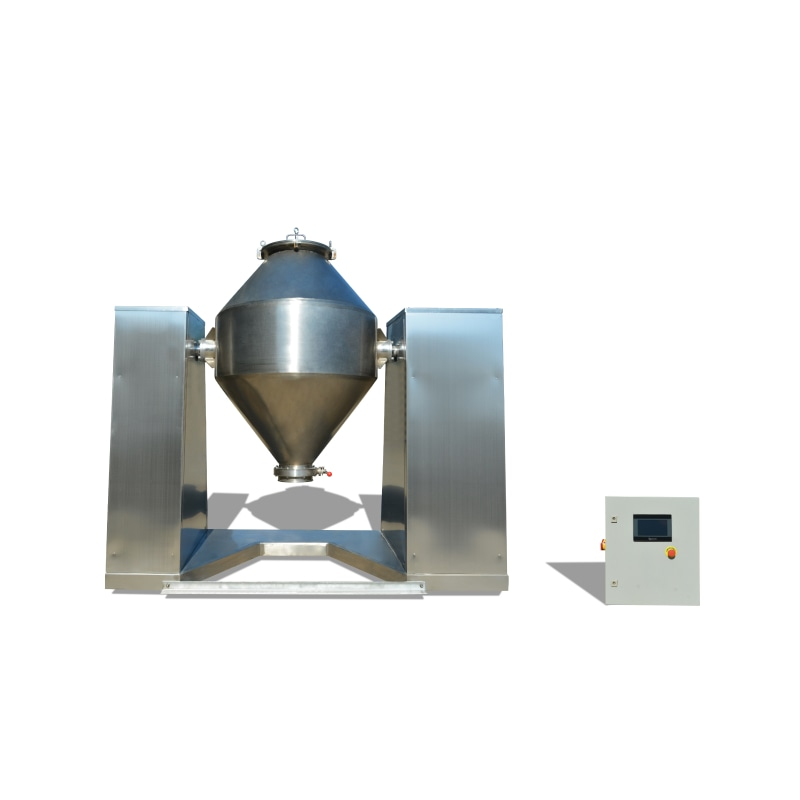

Structural Characteristics

The Double Cone Blender plays a role in different industries due to its effectiveness, in mixing powders and granules efficiently. Its design consists of two sections connected at the base to promote consistent mixing as the blender rotates. A key aspect is the Double Flange Concentric Taper that aids in distributing materials inside the blender to improve the blending process.

Operating Principle

The operating principle of the Double Cone Blender revolves around its rotational motion, which facilitates the tumbling action necessary for effective mixing. As the blender rotates, materials are lifted from the bottom and cascade through the center, promoting thorough intermingling. This mechanism is particularly beneficial for achieving homogeneity without requiring high-speed rotation or excessive energy input.

Comparing Double Cone Blenders with Other Tumble Blenders

Similarities with V-Blenders

Double Cone Blenders have similarities with V Blenders. Another commonly used tumble blender type.They both use gravity and rotation to mix substances.These blenders are ideal for mixing powders and granules making them a flexible option, for industries needing gentle yet thorough blending processes.

Differences from V-Blenders

While Double Cone Blenders and V Blenders share some similarities in their functions and uses in mixing processes they differ notably in their structures; V Blenders feature a chamber with a V shape whereas Double Cone Blenders are composed of two conical sections. This structural contrast influences how effectively they mix substances and their compatibility with materials. Moreover the innovative sided honeycomb layout present, in certain upgraded variations of Double Cone Blenders can boost mixing efficiency by offering more surface area for materials to interact during the blending process.

Applications and Industry Usage

Industries Benefiting from Double Cone Blenders

Double Cone Blenders are widely utilized in sectors because of their effectiveness and adaptability.They are commonly seen in the field for mixing active pharmaceutical ingredients (APIs) with excipients.Additionally in the food industry they are used for blending spices and flavorings. In chemical production where accurate mixtures are essential.

Material Handling Capabilities

Double Cone Blenders are known for their versatility in accommodating material types and densities making them a preferred choice for tasks that demand gentle treatment of delicate or vulnerable materials susceptible to damage, with more vigorous mixing techniques.

Features and Options of Double Cone Blenders

Standard Features

Double Cone Blenders usually come with stainless steel construction for longevity and easy cleaning purposes and also incorporate safety measures such as interlocked guards to safeguard operators while in use. Moreover the double action mechanism of these blenders facilitates movement and even distribution of materials, inside the blending chamber.

Optional Enhancements

To improve their performance more effectively and conveniently adjust the mixing processs speed as needed to suit various requirements in Double Cone Blenders offers advanced features like variable speed drives that allow for enhanced functionality and flexibility.Additionally some versions come with mixers that provide functions such, as the ability to heat or cool ingredients to meet specific processing needs.

By grasping these elements people can gain a deeper understanding of the valuable role Double Cone Blenders play in enhancing material processing efficiency in various sectors. Their distinct design features and operational benefits position them as instruments, for maintaining uniform product excellence and streamlining production processes.

Advantages of Using Double Cone Blenders

Operational Benefits

Double Cone Blenders provide a range of advantages that make them attractive to different industries They are designed in a way that promotes effective mixing with minimal energy use by utilizing rotational motion for the necessary tumbling action They are efficient due to their dual action mechanism which ensures uniform movement and distribution of materials inside the blending chamber The gentle mixing process is especially useful for handling materials and helps minimize the potential, for damage or degradation during blending operations

Design Advantages

The benefits of Double Cone Blenders design stem from the way they are structured with two conical sections meeting at the base to ensure mixing results efficiently They also feature a Double Flange Concentric Taper that helps evenly distribute materials, within the blenders interior space Moreover some upgraded versions include a dual honeycomb pattern which increases surface area encouraging better material interaction and enhancing blending effectiveness

Customization and Control Solutions

Custom Options Available

To meet the requirements of different industries Double Cone Blenders can be personalized with various features. These modifications might involve using materials, like stainless steel or alternative alloys to meet specific standards and operational needs. Furthermore the blenders can be fitted with linings or coatings to manage rough or corrosive substances effectively. The capability to adjust these blenders for uses enhances their adaptability and usefulness across a variety of fields.

Advanced Control Systems

Cutting edge control mechanisms play a role in contemporary Double Cone Blenders by granting operators meticulous command over the blending procedure.Exclusive attributes such as speed mechanisms enable modifications in rotational velocity that enhance mixing durations and uphold uniform product excellence.In addition to this enhancement is the incorporation of automated setups to oversee and manage factors like temperature and moisture levels for operations, with delicate materials.

Maintenance and Safety Considerations

Maintenance Ease

Maintaining equipment like Double Cone Blenders is crucial for smooth operation and longevity of the machinery, as a whole.Their uncomplicated yet sturdy structure allows for cleaning and upkeep tasks.Seals and bearings can be swiftly. Replaced to reduce downtime and keep operations running smoothly.Establishing maintenance routines can help extend the equipments lifespan and ensure it performs at its best.

Safety Features

Safety is extremely important in environments and Double Cone Blenders come with various features to ensure the safety of operators and maintain a secure working environment. One of the safety features is the interlocked guards that prevent access to moving parts while the equipment is in operation. Moreover; emergency stop mechanisms are also included in the control systems to enable operators to stop operations in case of an emergency. These safety protocols not ensure compliance with industry regulations but also help protect personnel, against potential dangers.

Exploring the aspects of Double Cone Blenders, including their operational advantages, customization possibilities and safety features showcases why they are a popular option across industries looking for effective and dependable mixing solutions. Their versatility and sturdy construction make them essential tools, for achieving top notch product results while ensuring operations.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness