The Future of API Pumps: Key Trends and Technology Innovations

API pump technology is quickly advancing due to technological developments in material science and smart technologies for the aim of making energy efficiency and performance better in highly industrialized sectors that heavily rely on secure and high-performance pump solutions. Breakthrough advancements such as corrosion alloys and smart monitoring systems are transforming the nature of these necessary pumps and how they operate and perform. Research the function of these new trends in so far as promoting efficiency, sustainability, and general performance in industry applications.

New Trends in API Pump Technology

With the changing world of pump technology, today's best innovation is being offered by API pumps that are meeting the increasing demands of industries for better and more efficient ways of meeting their needs. These vital equipment are being shaped by emerging trends ranging from developments in material science to the application of smart technologies which are leading the way in developing API pumps with tremendous technological advancements being made.

Advances in Material Science for API Pumps

The material science plays an important role in improving the efficiency and lifespan of API pumps in petrochemical and coal chemical industries using special alloy material such as anti-dilute sulfuric acid and corrosive resistant super low carbon duplex stainless steel pumps to manage aggressive chemicals, i.e., hydrochloric acid and caustic soda effectively with enhanced corrosion resistance capacity.

Highlighting material innovation ensures that API pumps are able to withstand conditions while maintaining efficiency and reliability. This advancement not only extends the life of pumps but also reduces maintenance costs and process disruptions for consumers.

Integration of Smart Technologies

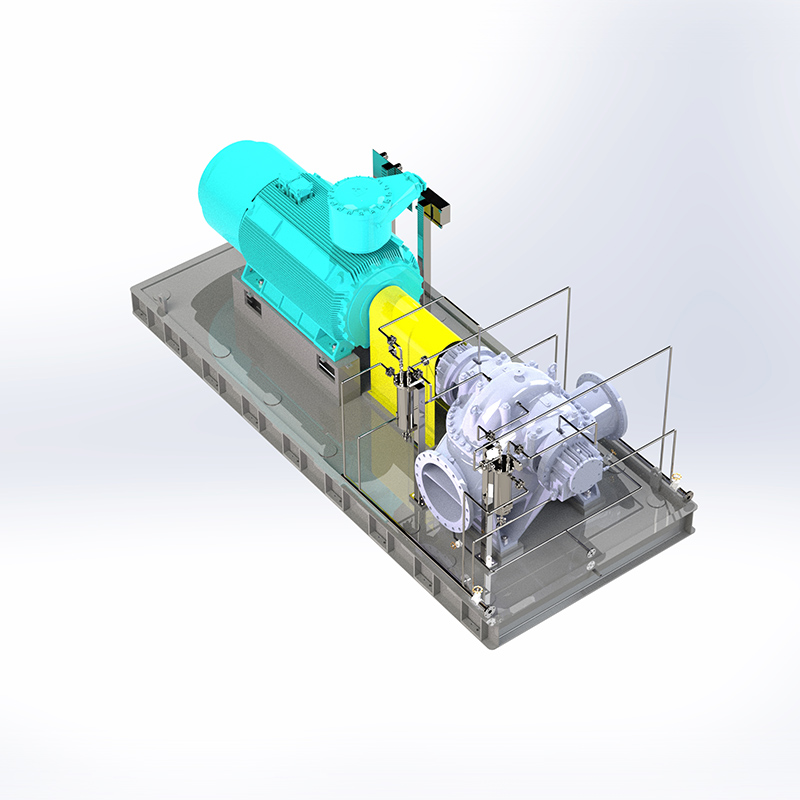

The incorporation of technologies into API pumps is revolutionizing the way these machines function and are serviced. By utilizing tools such as three-dimensional design and simulation methods manufacturers can conduct detailed analyses of numerous factors such as internal flow patterns, pressure distributions, and thermodynamic properties. This helps ensure that products manufactured meet, quality standards while minimizing operational uncertainties.

Sophisticated technologies also support monitoring and preventive maintenance functions that help the users to optimize the efficiency of pumps and avert potential break downs. This trend in direction towards systems boosts productivity within operation and facilitates useful knowledge about the operation of pumps.

Improvements in energy efficiency

In today's pump technology, the importance of energy efficiency cannot be stated strongly enough. The hydraulic efficiency point of the new BB22 centrifugal pump stands at 90.m% representing excellent improvements in energy performance. This means less energy usage. Lower operating costs for industries that depend on API pumps.

Manufacturers continue through prioritizing energy designs that come up with affordable solutions for consumers and also improve the environment as well as meeting industry needs for sustainable means.

Technology Breakthroughs Setting the Course of the Future

Before the future are upcoming developments that will reshape the way API pumps operate. These breakthroughs are pushed by the urge towards more automation better accuracy in production practices and more commitment to sustainability.

Automation and Control Systems in API Pumps

The use of control systems in API pump operations is transforming the industry by enhancing accuracy and reliability to great levels. Automatic systems are made to pass testing procedures for regular pumps like hydraulic performance tests and endurance tests. This automation guarantees consistent excellence, across production lines.

These systems are simple to integrate into infrastructure and enable users to take advantage of automated processes that minimize errors and maximize levels of productivity. Automation is part of a trend towards more intelligent industrial solutions with emphasis on efficiency and precision.

3D Printing Applications in Pump Manufacturing

3-D printing technology is becoming increasingly popular in pump production because it allows for the manufacturing of parts with very high accuracy and precision rates. With 3D laser printing technology, manufacturers can quickly and accurately test their products for validations.

It hastens prototyping. Also accommodates custom fit according to distinctive client specifications nicely. The ability presented by 3D printing for making alterations is creative since there are no expenses of undertaking large-scale retooling or lost time.

Environmental Considerations and Sustainability

The pump industry is more focused than ever before to take environmental concerns into account while making decisions on their practices and operations. Yantai Longgang Pump Industry Co. Ltd believes in sustainability by prioritizing sharing resources to the maximum extent and building relationships with customers and encouraging sustainable practices in all areas of business.

Manufacturers market their commitment to conservation and innovation by creating energy-efficient products like the aforementioned or engage in ventures aimed at cutting carbon footprints, like the " Qily Petrochemical. Shengli Oilfield Million Tons CCUS Project."

Future advancements in API pumps mirror improvement across multiple fronts. This includes the improvement of materials to handle contents the incorporation of smart technologies to track in real-time as well as the utilization of 3D printing to speed up prototyping. Additionally, there is a greater focus on sustainability steps that are making a visible contribution towards industry culture as a whole.

Challenges and Opportunities Ahead for API Pumps

The changing and dynamic field of pump technology necessitates focusing on meeting the respective needs of a range of different industries in next steps of further API pump developments to survive and remain relevant in the market.

Serving Industry-Specific Needs

API pumps are utilized in industries where reliability and efficiency rank high on their agendas. Yantai Longgang Pump Industry Co. Ltd has established itself as a name in the provision of tailored solutions that respond to the distinct demands of various industries. Focusing, in particular, on innovation and independently conducted research activities, the company is in the habit of hiring professional pump designers in regular intervals in order to strengthen its technical base. Such practice enables them to innovate and introduce products that prevail over industry-related challenges in effective ways.

A case in point is creating alloy pumps utilized in dealing with extremely corrosive chemicals that shows comprehension of the particular requirements in the industry segment they serve. These materials provide corrosion resistance which makes them suitable for harsh conditions in environments such as in the petrochemical and coal chemical industries.

Besides that, Yantai Longgang Pump Industry Co. Ltd works with leading institutions, including Shandong University and Zhejiang Sci-Tech University to be engaged in industry academia research collaborations. This partnership allows for the creation of innovative products specifically tailored to address changing market needs.

Market Dynamics and Competitive Landscape

The API pump market is driven by factors such as industry needs-based technological advances and market trends for better and more superior solutions The manufacturers need to effectively deal with these factors to stay competitive.

The reputation of Yantai Longgang Pump Industry Co. Ltd is built on its focus towards industry-leading products and high standards of customer service. The company has been certified with quality such as ISO9001, 2008 and American Petroleum Institute API quality system certification which has earned them approval from satisfied customers for high quality and improved service options. The positive feedback from customers has positioned the company as a first-class supplier to organizations like China National Petroleum Corporation (CNPC) and Sinopec.

In order to ensure leadership among the market rivalry, the companies have to lay emphasis on prompt delivery of services and customer satisfaction. Yantai Longgang Pump Industry Co., Ltd offers quality spare parts according to customer specifications and keeps regular follow-up visits to acquire feedback on the performance of products. The determination of the firm to resolve problems related to quality within a single day ensures help to customers in case of requirement.

Further, market trends are also driven by the rising use of automation in pump operations brought about by control systems that further increase accuracy and dependability. By integrating these technologies into manufacturing processes such as CNC machining centers or computer-controlled drills (e.g., CNC gantry drilling) businesses can enhance production efficiency and uphold superior quality standards.

Briefly, future growth of API pumps depends on meeting industry demand through innovative strategies and maintaining competitive industry conditions driven by technology innovations intended to maximize working efficiency in various world industrial sectors.

https://www.lg-pumps.com/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness