How Can a Jumbo Bag Filling Machine Transform Bulk Material Handling?

Industries that deal with large volumes of bulk materials constantly face challenges related to efficiency, accuracy, and labor costs. Whether in agriculture, construction, chemicals, or food processing, the need for a reliable and effective packaging solution is undeniable. This is where a jumbo bag filling machine becomes a game-changer. But how exactly does it transform bulk material handling? Let’s break it down in simple terms, making it easy to understand why this machine is an essential tool for businesses dealing with large-scale packaging.

What Is a Jumbo Bag Filling Machine?

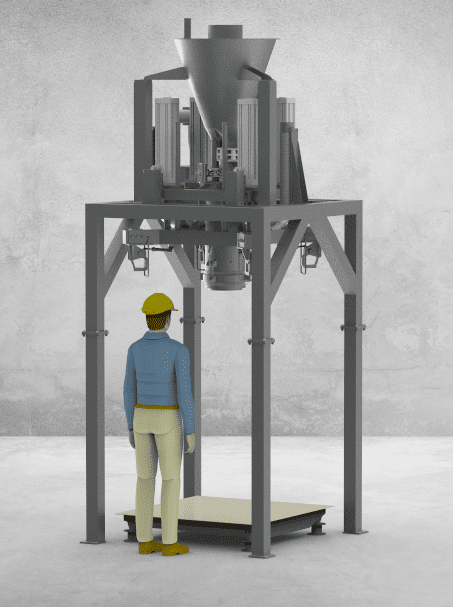

A jumbo bag filling machine is an industrial device designed to fill large bags—often called FIBCs (Flexible Intermediate Bulk Containers), bulk bags, or big bags—with various dry materials such as grains, powders, granules, and aggregates. Instead of relying on manual labor, which can be slow and inconsistent, this machine automates the process, ensuring speed, precision, and safety.

This type of equipment is commonly used in industries where bulk storage and transport are necessary. The machine typically features a sturdy support frame, a weighing system, a filling spout, and sometimes dust control mechanisms to keep the work environment clean and minimize waste.

Why Should Businesses Invest in a Jumbo Bag Filling Machine?

Bulk material handling can be messy, inefficient, and labor-intensive when done manually. A jumbo bag filling machine helps solve these common industry problems, making operations smoother and more cost-effective.

1. Faster and More Efficient Filling

Manually filling large bags takes time and requires significant labor. A jumbo bag filling machine automates the process, dramatically reducing the time needed to fill each bag. With some machines capable of filling multiple bags per hour, businesses can increase their output without hiring more workers.

2. Precision in Weight Measurement

Overfilling or underfilling bags can lead to inconsistencies in shipping and increased material costs. A jumbo bag filling machine comes with a built-in weighing system that ensures every bag is filled to the exact required weight. This level of precision helps businesses save money by minimizing material loss and ensuring compliance with shipping regulations.

3. Reduced Material Waste

Spillage and material loss can significantly impact profitability. Manual filling often results in wasted product due to inefficient handling. The controlled filling mechanism of a jumbo bag filling machine ensures that material is directed straight into the bag, minimizing losses and keeping the workspace clean.

4. Improved Workplace Safety

Handling large bags manually can be physically demanding and poses risks of injuries. Employees may suffer from back strains, slips, and exposure to hazardous materials. A jumbo bag filling machine reduces these risks by automating heavy lifting and material handling, creating a safer work environment.

5. Versatility Across Industries

Different industries require different handling solutions. Whether working with fine powders, coarse granules, or bulky materials, a jumbo bag filling machine can be adjusted to meet the specific needs of various products. This makes it a flexible investment for businesses across multiple sectors.

How Does a Jumbo Bag Filling Machine Work?

The working principle of a jumbo bag filling machine is simple yet highly effective. The process generally involves the following steps:

1. Bag Placement and Secure Attachment

An empty jumbo bag is placed under the filling station and securely attached to the machine. Most machines have hooks or clamps to hold the bag in place, preventing movement during the filling process.

2. Inflation and Material Filling

To ensure the bag stays open, some machines use an inflation system before filling begins. The material is then discharged into the bag through a filling spout. Depending on the type of product, the filling mechanism can work using gravity, screw feeders, or pneumatic systems.

3. Weight Monitoring and Auto Shut-Off

As the bag fills, the machine continuously monitors the weight. Once the pre-set weight is reached, the filling process stops automatically. This prevents overfilling and ensures consistency across all filled bags.

4. Bag Sealing and Removal

Once filled, the bag is sealed, either manually or automatically, to prevent spillage during transportation. The bag is then removed from the machine, making way for the next cycle.

Features to Look for in a Jumbo Bag Filling Machine

If you’re considering investing in a jumbo bag filling machine, here are some key features to look for:

- High-precision weighing system – Ensures accurate filling with minimal weight variation

- Adjustable filling speed – Allows customization based on material type and workflow needs

- Dust control system – Keeps the environment clean, especially when handling fine powders

- Sturdy construction – Provides long-lasting durability for industrial applications

- Easy-to-use interface – Reduces training time and makes operation more straightforward

- Compatibility with various materials – Ensures flexibility in different industrial settings

Industries That Benefit from Jumbo Bag Filling Machines

A jumbo bag filling machine is a valuable tool across many industries. Here’s how different sectors benefit from this advanced packaging solution:

- Agriculture and Food Processing – Used for filling bulk bags with grains, seeds, flour, sugar, and other food products

- Construction and Mining – Ideal for packaging cement, sand, gravel, and minerals

- Chemical Industry – Ensures safe handling of fertilizers, industrial powders, and chemicals

- Plastics and Polymers – Efficiently fills bags with plastic resins, granules, and powders

- Pharmaceuticals – Provides contamination-free filling for bulk medical and pharmaceutical products

Is Investing in a Jumbo Bag Filling Machine Worth It?

The initial cost of a jumbo bag filling machine may seem like a significant investment, but the long-term benefits far outweigh the cost. Companies that invest in automated filling solutions experience:

- Lower labor costs – Fewer workers are needed for the filling process

- Higher productivity – More bags are filled in less time, boosting overall output

- Consistent quality – Every bag is filled with precise accuracy, reducing errors

- Less material loss – Controlled filling means minimal waste and maximum savings

Over time, these advantages contribute to a quick return on investment, making the machine a smart and cost-effective solution for businesses dealing with bulk materials.

Final Thoughts: A Smarter Way to Handle Bulk Materials

A jumbo bag filling machine is more than just a convenience—it’s a necessity for industries that require efficient, accurate, and safe bulk material handling. By automating the process, businesses can reduce waste, cut costs, improve workplace safety, and enhance overall productivity.

For companies looking to streamline their operations and maximize efficiency, investing in a jumbo bag filling machine is a step toward a more profitable and sustainable future. If your business handles bulk materials, it’s time to consider how automation can take your operations to the next level.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness