How Does 3D Print on Demand Transform Your Ideas into Reality?

How Does 3D Print on Demand Work?

What Are the Steps Involved in the Process?

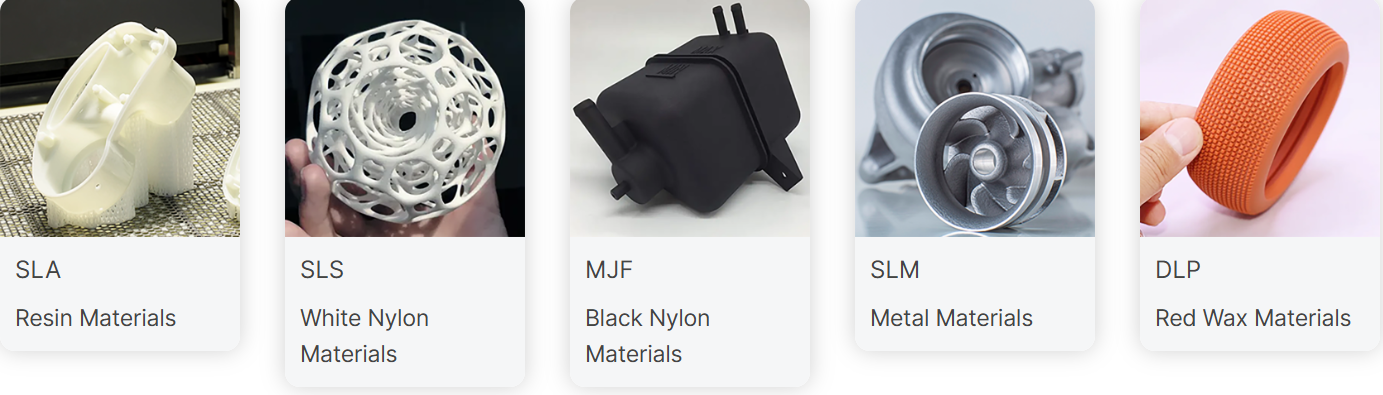

3D Print on Demand —the service that allows you to convert a digital design to a real-world product. It starts with the creation of a digital blueprint through the use of CAD (computer-aided design) software. The model is then cut in the horizontal slices which will used by the 3D printer. Based on these guidelines, The printer builds the object layer by layer which varies in technology like SLA, SLS, MJF, and SLM. It enables the production of intricate forms and geometries that may be very challenging, if not infeasible to produce, using conventional manufacturing processes.

How Can You Submit Your Design for Printing?

It has never been easier to submit your design for 3D printing. And with Momaking being user-friendly, you will have to only upload your drawings and in seconds get a quote. Such a quick AI quote system is easily able to become accurate for different forms of drawing thereby making it both easy and convenient for both individual and business enterprises to create their products.

What Materials Can Be Used in 3D Printing?

The range of materials that can be used only enhances the versatility of 3D printing. The list goes on with materials from plastics such as PLA and ABS to metal powder or photosensitive resins. The industrial-grade 3D printing machines of MOMAKING can print a wide combination of high-performance engineering resins, enabling them to serve industries like aerospace, automobile manufacturing, and medical equipment.

What Are the Benefits of Using 3D Print on Demand?

How Does It Save Time and Resources?

The greatest advantage of 3D Print on Demand is the time and resources it conserves. 3D printing allows product prototypes to be quickly manufactured for design validation, functional testing, and market research to be conducted, whereas traditional manufacturing methods require large and expensive tooling and long setup times. In conventional manufacturing, the product prototypes are made with explicit tooling and setup times, while through 3D printing, it is possible to manufacture product prototypes for design validation, functional testing, and market research in a short time.

In What Ways Is It Cost-Effective?

This technology is also very cost-effective – another strong advantage of it. It drastically reduces production costs by allowing customers to make highly customized products with very few resources, unlike traditional types of manufacturing that require molds and therefore produce a lot of wastage. It can produce highly customized products based on the specific needs of customers at lower production costs by removing the need for molds and reducing material waste.

How Can It Enhance Creativity and Innovation?

There is no art of 3D printing, it opens so many doors to creativity. Gone are the days when designers were limited by the capabilities of traditional methods of manufacturing; with the aid of technology, new forms and structures are largely accessible. It easily creates complex shapes of geometry that are otherwise hard for traditional processes to achieve, hence allowing for innovation in different disciplines. And it can simply create complex geometries that are much easier to do than other traditional processes that inspire creativity in different areas.

Why Choose 3D Print on Demand with Momaking?

What Are the Unique Services Offered by Momaking?

What sets Momaking apart is its all-inclusive offerings that cater to a wide array of requirements. Armed with more than 400+ industrial-grade 3D printers, it ensures an unmatched precision level and fast delivery of high-quality prints. Armed with more than 400+ industrial-grade 3D printers, they provide high precision and speed in the supply of quality prints.

How Does Momaking Ensure Quality and Precision?

Quality assurance is one of the pillars of Momaking. Microsystem machines are industrial-grade with ultra-precision details engineered to fully comply with the stringent precision manufacturing industry's requirements, confirming that every product has an exacting specification. From Complex Parts Processing to Making of Accuracy Medical Devices — Momaking Only Delivers The Best. Momaking delivers quality every single time whether you need a complex part to be processed or a small medical device to be manufactured.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness