Troubleshooting PMSM: Expert Tips for Common Challenges

Understanding PMSM Basics

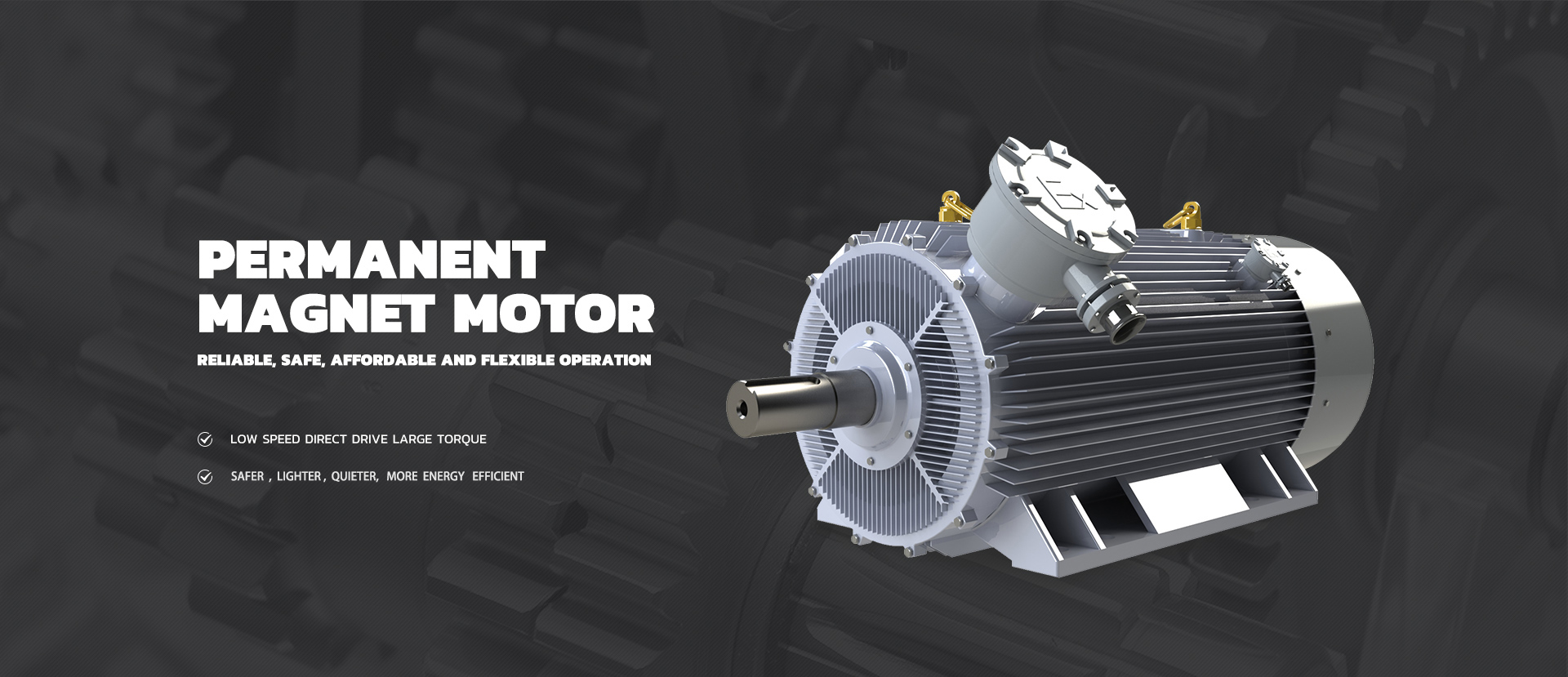

Overview of Permanent Magnet Synchronous Motors

Permanent Magnet Synchronous Motors ( referred to as PMSMs) are a specific kind of synchronous motor that incorporates permanent magnets within the rotor assembly rather than relying solely upon electric currents for magnetization purposes. These motors have gained recognition for their efficiency levels and compact form factor which make them ideal for applications where space is limited and energy conservation is crucial. Moreover; PMSMs offer control, over both speed and position settings..

They are extensively utilized in a variety of settings owing to their superior performance attributes when compared to alternative motor varieties.

Key Components and Their Functions

The primary components of a PMSM include the stator, rotor, and permanent magnets. The stator contains windings that produce a rotating magnetic field when powered by an AC supply. The rotor, which houses the permanent magnets, aligns with this magnetic field, causing the rotor to turn at the same speed as the stator's magnetic field. This synchronous operation is what gives PMSMs their name.

Benefits and Applications of PMSM

There are advantages to using PMSMs like increased efficiency and lower energy usage along with a great torque to weight ratio which makes them perfect for electric cars and automated systems in industries like aerospace and robotics due to their capacity to sustain a steady speed even when handling different loads, for precise tasks.

Identifying Common PMSM Issues

Motor Overheating Problems

Causes of Overheating in PMSM

Overheating in PMSMs can result from excessive current draw, inadequate cooling systems, or poor ventilation. Other contributing factors include overloading the motor beyond its rated capacity or operating it at high ambient temperatures without proper thermal management.

Preventive Measures for Overheating

To avoid issues with the motor and maintain optimal performance of the cooling systems in place by checking for any blockages, in the ventilation pathways periodically and installing temperature monitoring systems to detect any signs of overheating early.

Vibration and Noise Concerns

Sources of Vibration in PMSM

Vibrations in PMSMs can arise from mechanical imbalances within the rotor assembly or misalignment between the motor shaft and connected load. Additionally, electromagnetic forces within the motor can contribute to vibration if not properly managed.

Solutions to Minimize Noise

To reduce noise it's important to carefully balance the rotor assembly and make sure all mechanical parts are properly aligned. Using materials that dampen vibrations and isolators can also be effective, in lowering transmitted vibrations. Regular maintenance inspections can pinpoint noise sources early on preventing them from developing into larger problems.

Electrical Challenges in PMSM Operation

Insulation Failures and Their Impact

Types of Insulation Failures in PMSM

Insulation issues may arise from factors like heat-induced degradation or mechanical wear and tear alongside strain exposure risks too often leading to partial discharge breakdowns or deterioration due, to tough environmental conditions.

Techniques for Insulation Maintenance

Periodic checks with insulation resistance testing can uncover indications of insulation degradation. Applying coatings or barriers can safeguard the insulation, against environmental elements. Securing connections properly alleviates strain placed upon the insulation materials.

Power Supply Irregularities

Effects of Voltage Fluctuations on PMSM

Voltage fluctuations can lead to inconsistent motor performance, increased heat generation, and potential damage to electrical components within the motor. Prolonged exposure to unstable power supply conditions may shorten the lifespan of a PMSM.

Strategies for Stabilizing Power Supply

Maintaining a power supply requires the use of voltage regulators or uninterruptible power supplies (UPSs) which ensure a steady flow of voltage levels is maintained consistently over time. Additionally incorporating surge protection devices can protect against voltage surges that may potentially damage components of motors.

Mechanical Troubleshooting Techniques

Bearing Failures in PMSM

Identifying Signs of Bearing Wear

Signs of bearing wear include unusual noises such as grinding or squealing during operation, increased vibration levels, and visible wear marks on bearing surfaces. Monitoring these indicators helps in the early detection of potential bearing issues.

Best Practices for Bearing Maintenance

Consistently maintaining lubrication as outlined by the manufacturer is essential to extend the lifespan of bearings conducting regular checkups to detect any wear and tear and replacing bearings when needed is important for their longevity and ensuring correct alignment during installation will prevent unnecessary strain, on the bearings.

Shaft Misalignment Issues

Consequences of Shaft Misalignment

Shaft misalignment could cause vibration levels and premature bearing failure while also leading to increased wear on coupling parts and reduced efficiency due, to extra mechanical losses.

Methods for Correcting Alignment

Aligning properly requires the use of alignment equipment like laser alignment systems to guarantee exact positioning, between linked shaft components. It's essential to conduct inspections following maintenance tasks that could impact alignment configurations.

Advanced Diagnostic Tools for PMSM

Utilizing Thermal Imaging for Motor Assessment

Thermal cameras offer a look at how heat is spread out over a surface without the need for invasive testing methods like X-rays or scans. This helps pinpoint areasthat aree hotter than normal indicating potential problems, like airflow issues or electrical malfunctions.

Vibration Analysis Tools and Techniques

Tools for analyzing vibrations detect patterns linked to mechanical issues like imbalances or misalignments in a motor system m.To anticipate failures, in advance, technicians examine these patterns regularly over time.

Implementing Online Monitoring Systems

Continuous online monitoring systems track factors like changes in temperature and vibration levels as well as electrical performance metrics inreal-timee to help implement proactive maintenance plans by issuing alerts when any abnormalities, from usual operational conditions are identified.

Enhancing Performance and Reliability

Regular Maintenance Schedules

Ensuring that you schedule maintenance tasks helps in conducting timely checks and servicing operations customized for every part of a PMSM system ultimately improving its overall reliability and reducing the chances of unexpected failures causing downtime risks.

Upgrading to Advanced Control Systems

Advanced control systems provide precision compared to traditional methods by using advanced algorithms to adjust operational settings in real-time based on feedback. This leads to performance under different load conditions without sacrificing efficiency a significant upgrade, from the conventional approaches commonly used across industries worldwide today!

Training Personnel for Efficient Troubleshooting

Staff training provides employees with the knowledge to effectively troubleshoot complex issues that arise during daily operations involving advanced equipment such as modern Permanent Magnet Synchronous Motors (PMSMs). In-depth training programs that combine learning with hands-on practical experience help in the development of skills needed to tackle challenges efficiently consequently reducing the need, for external expertise and leading to long-term cost savings.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness