Machine Condition Monitoring Market Demand, Overview, Market Drivers, Forecast 2025-2032

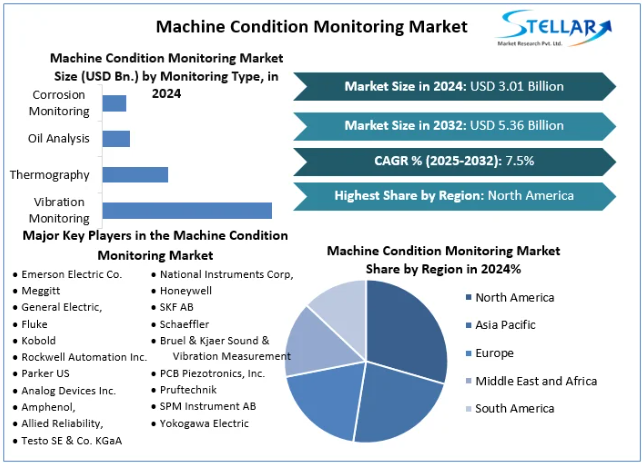

Machine Condition Monitoring Market Demand was valued at USD 3.01 Billion in 2024 and the total Machine Condition Monitoring Market size is expected to grow at a CAGR of 7.5% from 2025 to 2032, reaching nearly USD 5.36 Billion by 2032.

Market Definition and Scope

Machine condition monitoring involves continuous assessment of machinery health and performance through vibration analysis, thermal imaging, oil analysis, and ultrasound detection. These technologies help in early detection of faults, prevention of unexpected failures, and optimization of maintenance schedules, significantly reducing repair costs and production losses. The market is expanding across sectors such as manufacturing, energy, oil & gas, aerospace, and transportation, where predictive maintenance is crucial for maximizing equipment lifespan and ensuring operational reliability.

Get your sample copy of this report now! https://www.stellarmr.com/report/req_sample/Machine-Condition-Monitoring-Market/1729

Market Growth Drivers and Opportunities

-

Rising Adoption of Predictive Maintenance Strategies

- Industries are moving from reactive and preventive maintenance to condition-based and predictive maintenance to enhance equipment reliability.

- The integration of AI and IoT-based monitoring solutions allows for real-time machine health tracking.

-

Advancements in IoT and Cloud-Based Condition Monitoring

- The use of IoT sensors and cloud computing enables remote monitoring and real-time analytics.

- Wireless sensor networks (WSNs) and AI-driven analytics help in predictive failure analysis and automated alerts.

-

Increased Focus on Industrial Safety and Compliance

- Government regulations emphasizing worker safety and machine reliability are driving demand for condition monitoring solutions.

- Industries such as oil & gas, power generation, and aviation are investing in advanced monitoring technologies to comply with safety standards.

-

Growing Demand for Cost-Effective Maintenance Solutions

- Companies are seeking data-driven maintenance approaches to cut down on unplanned downtime and expensive repairs.

- Machine condition monitoring provides a high return on investment (ROI) by extending equipment life and reducing operational risks.

-

Expansion of Smart Manufacturing and Industry 4.0

- The rise of automation, robotics, and AI-driven diagnostics is accelerating the adoption of predictive maintenance tools.

- Digital twins and real-time asset monitoring are reshaping industrial maintenance strategies.

Segmentation Analysis

The Machine Condition Monitoring Market is segmented based on monitoring technique, deployment mode, component, industry vertical, and region:

-

By Monitoring Technique

- Vibration Monitoring (widely used for early fault detection)

- Thermal Imaging (identifies overheating and insulation failures)

- Ultrasound Detection (detects leaks and component wear)

- Oil Analysis (monitors lubricant quality and contamination)

- Corrosion Monitoring (crucial for oil & gas and chemical industries)

-

By Deployment Mode

- On-Premises (traditional, in-house monitoring solutions)

- Cloud-Based (remote and real-time data access via cloud platforms)

-

By Component

- Hardware (sensors, vibration analyzers, infrared cameras)

- Software (predictive analytics, AI-driven diagnostics)

- Services (installation, consulting, and maintenance)

-

By Industry Vertical

- Manufacturing (predictive maintenance in production lines)

- Oil & Gas (minimizing unplanned shutdowns in refineries)

- Power Generation (enhancing efficiency in wind and thermal plants)

- Automotive & Transportation (monitoring vehicle and railway components)

- Aerospace & Defense (ensuring aircraft safety and reliability)

To delve deeper into this research, kindly explore the following link: https://www.stellarmr.com/report/Machine-Condition-Monitoring-Market/1729

Country-Level Analysis

-

United States

The U.S. is leading the global market due to early adoption of predictive maintenance technologies, strong investments in smart factories, and the presence of key players. The aerospace, energy, and automotive industries are major adopters of IoT-enabled machine condition monitoring solutions. -

Germany

Germany, a hub for advanced manufacturing and Industry 4.0 initiatives, is witnessing rapid deployment of AI-driven machine monitoring solutions. The country’s high emphasis on automation and precision engineering is fueling demand for real-time asset monitoring systems.

Competitive Landscape

The Machine Condition Monitoring Market is characterized by the presence of global technology leaders, industrial automation firms, and predictive maintenance solution providers. Key players include:

- Honeywell International Inc. – Leading provider of industrial IoT and machine health monitoring solutions.

- General Electric (GE Digital) – Offers AI-driven predictive maintenance software for industrial applications.

- Emerson Electric Co. – Specializes in real-time machine diagnostics and vibration analysis solutions.

- SKF Group – Focuses on automated condition monitoring systems for rotating machinery.

- Rockwell Automation Inc. – Provides AI-integrated monitoring solutions for smart factories.

- ABB Ltd. – Expanding its cloud-based asset monitoring and predictive analytics portfolio.

Conclusion

The Global Machine Condition Monitoring Market is witnessing unprecedented growth, fueled by the shift towards predictive maintenance, the rise of Industry 4.0, and advancements in AI-driven analytics. As companies prioritize equipment reliability and operational efficiency, the demand for real-time machine health monitoring solutions is set to surge. With continued technological advancements and increasing adoption of IoT, AI, and cloud-based condition monitoring, the market is poised for sustained expansion in the coming years.

Our Trending Report :

South America Smart Wearables Market https://www.stellarmr.com/report/South-America-Smart-Wearables-Market/793

Philippines Video Surveillance Market https://www.stellarmr.com/report/Philippines-Video-Surveillance-Market/565

About Stellar Market Research:

Stellar Market Research is a multifaceted market research and consulting company with professionals from several industries. Some of the industries we cover include science and engineering, electronic components, industrial equipment, technology, and communication, cars, and automobiles, chemical products and substances, general merchandise, beverages, personal care, and automated systems. To mention a few, we provide market-verified industry estimations, technical trend analysis, crucial market research, strategic advice, competition analysis, production and demand analysis, and client impact studies.

Contact Stellar Market Research:

S.no.8, h.no. 4-8 Pl.7/4, Kothrud,

Pinnac Memories Fl. No. 3, Kothrud,

Pune, Maharashtra, 411029

sales@Stellarmarketresearch.com

+91 20 6630 3320, +91 9607365656

- Machine_Condition_Monitoring_Market_Demand

- Machine_Condition_Monitoring_Market_Trends

- Machine_Condition_Monitoring_Market_Analysis

- Machine_Condition_Monitoring_Market_Report

- Machine_Condition_Monitoring_Market_Overview

- Machine_Condition_Monitoring_Market_Revenue

- Machine_Condition_Monitoring_Market_Opportunities

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness