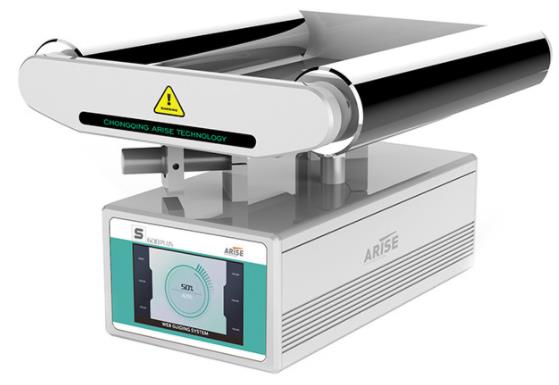

W500 All-in-one Web Guiding System For Edge Position Control

Arise is an audited, leading web guiding system manufacturer in China with a professional R & D team. Using the high precision web guiding equipment supplied by Arise can ensure continuous and accurate edge position control of coil materials in various production processes.

How Does the W500 All-in-one Web Guiding System

The web guide sensor emits infrared light, ultrasonic, laser, visible light to monitor the operation of the coil materials, and sends the signal to the controller. The controller finds the position drifts of coil materials, according to the instruction set by the controller in advance, the driver controls the swing of the frame to guide the coil position. The automatic web guide system adopts photoelectric sensor detecting the edge position of the coil materials, and the measured position deviation signal is sent to the controller. After the judgment and processing by the control unit, the drive motor is controlled to guide the coil with the deviation position to the correct position.

Advantages Of W500 All-in-one Web Guiding System

The web guide machine uses a 940nm infrared emitter tube and imported silicon photocells to accurately detect the deviation of the melt blown cloth. The drive system adopts low synchronization, frequency conversion speed regulation, stepping and servo motor drive. The stroke is strictly proportional to the offset of the coil materials.The servo motor drives the ball screw to precisely adjust the material deviation, and keep the edges and lines of coil materials at the designated position at any time.

1. Track the edge of the substrate, correct the unevenness of the substrate when winding.

2. Track the edge of the substrate to keep the coating material equidistant from the edge.

3. According to roll speeds of different materials, the correction speed can be adjusted to keep balance with it.

Main Applications Of W500 All-in-one Web Guiding System

The W500 all-in-one web guide system has been widely used in the applications of various industries and it is essential in industries such as packaging, printing, labels, building materials, paper pulp, metal processing, non-woven fabrics, corrugated paper processing, etc.

Tire industry: molding machine, carcass cord, laminating drum common template correction, inner liner pre-correction, film blowing machine, industrial belt laminating machine.

Packaging, printing and paper industries: satellite web printing machine, bump plate printing press machine, inspection machine, slitting rewinder, coating machine, etc.

Battery industry: lithium battery coating machine, lithium battery slitting machine, lithium battery rolling die machine, battery stacking machine.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness