Stress Resistance of Single Wall Paper Cup Factory Products

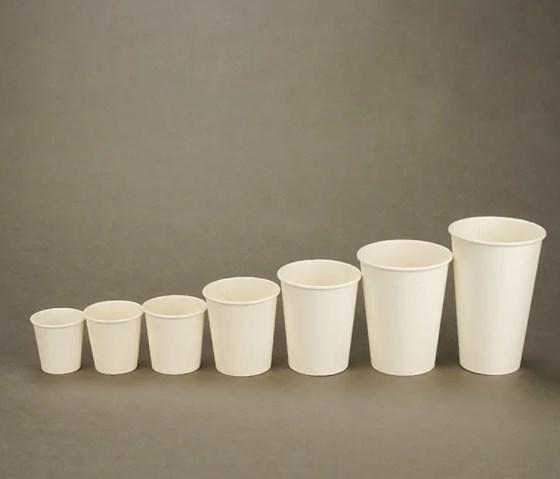

The Single Wall Paper Cup Factory has long been a cornerstone in the production of disposable tableware, and the product's compressive strength is a critical aspect of its functionality and reliability. The ability of a single wallpaper cup to withstand pressure without collapsing is essential for its use in various beverage services, from hot coffee to cold beverages. This article delves into the factors that contribute to the compressive strength of products from Single Wall Paper Cup Factory and how these factors are managed to ensure quality and performance.

The compressive strength of a single wallpaper cup is influenced by several factors, including the type of paper used, the thickness of the paper, and the manufacturing process employed by the Single Wall Paper Cup Factory. High-quality paper, such as food-grade paper, is chosen for its ability to hold liquids without leaking and to maintain its structural integrity under pressure. The thickness of the paper is another crucial factor; a thicker paper will naturally offer greater resistance to compression. However, it's a delicate balance, as increasing the thickness can also lead to increased costs and environmental impact, which is why Single Wall Paper Cup Factory must optimize the thickness for both strength and sustainability.

The manufacturing process at Single Wall Paper Cup Factory is designed to enhance the compressive strength of the cups. This includes the use of advanced machinery that ensures uniformity in the paper's thickness and the application of heat during the molding process, which helps to set the shape and increase the cup's rigidity. Additionally, the factory employs quality control measures to test the compressive strength of the cups at various stages of production, ensuring that any deviations from the desired strength are identified and corrected promptly.

One of the challenges faced by Single Wall Paper Cup Factory is to maintain the balance between the cup's compressive strength and its ability to insulate heat. While a thicker cup may be more resistant to compression, it may also conduct heat more effectively, which can be a disadvantage for hot beverages. To address this, the factory may incorporate special linings or coatings that provide insulation without compromising the cup's structural integrity.

The Single Wall Paper Cup Factory also focuses on the design of the cup's base and sidewalls. A well-designed base can distribute the weight of the liquid evenly, reducing the stress on any single point and thus enhancing the cup's compressive strength. Similarly, the sidewalls must be designed to resist bulging or collapsing under pressure, which requires precise engineering of the cup's shape and material properties.

In conclusion, the compressive strength of products from Single Wall Paper Cup Factory is a result of careful material selection, advanced manufacturing processes, and rigorous quality control. By focusing on these aspects, the factory ensures that its single wallpaper cups can withstand the pressures of everyday use while remaining a cost-effective and environmentally conscious choice for consumers. The ongoing commitment to innovation and improvement at Single Wall Paper Cup Factory is a testament to its dedication to producing high-quality, durable, and reliable single wall paper cups that meet the needs of the market.

https://www.hypapercup.com/product/single-wall-paper-cups/

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness