Understanding the Composition and Properties of Wood Pulp Fiber Wet Film

Wood pulp fiber wet film is a versatile material that finds applications in various industries, including packaging, textiles, and construction. This article aims to provide a comprehensive understanding of the composition and properties of wood pulp fiber wet film, shedding light on its unique characteristics and potential benefits. By delving into its composition and exploring its properties, we can gain insights into why this material is gaining popularity and revolutionizing multiple sectors.

I. Composition of Wood Pulp Fiber Wet Film

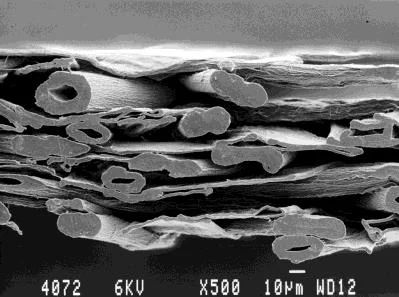

Wood pulp fiber wet film is primarily composed of cellulose fibers derived from wood pulp. These fibers are obtained through a mechanical or chemical pulping process, where wood chips are broken down into individual fibers. The resulting cellulose fibers are then mixed with water and other additives to form a slurry, which is further processed to create the wet film.

A. Cellulose Fibers:

Cellulose fibers are the main building blocks of wood pulp fiber wet film. These fibers provide the material with its strength, flexibility, and other desirable properties. The length, diameter, and arrangement of cellulose fibers play a crucial role in determining the characteristics of the wet film.

B. Additives:

Various additives are incorporated into the wood pulp fiber wet film to enhance its performance and tailor it for specific applications. These additives may include binders, fillers, coatings, and water-resistant agents. The choice and concentration of additives depend on the desired properties and intended use of the wet film.

II. Properties of Wood Pulp Fiber Wet Film

Wood pulp fiber wet film possesses a unique set of properties that make it suitable for a wide range of applications. Understanding these properties is essential for harnessing the full potential of this material.

A. Strength and Durability:

Wood pulp fiber wet film exhibits excellent strength and durability, making it suitable for demanding applications. The inherent strength of cellulose fibers, combined with the bonding provided by additives, contributes to the material's ability to withstand mechanical stress and maintain structural integrity.

B. Flexibility and Versatility:

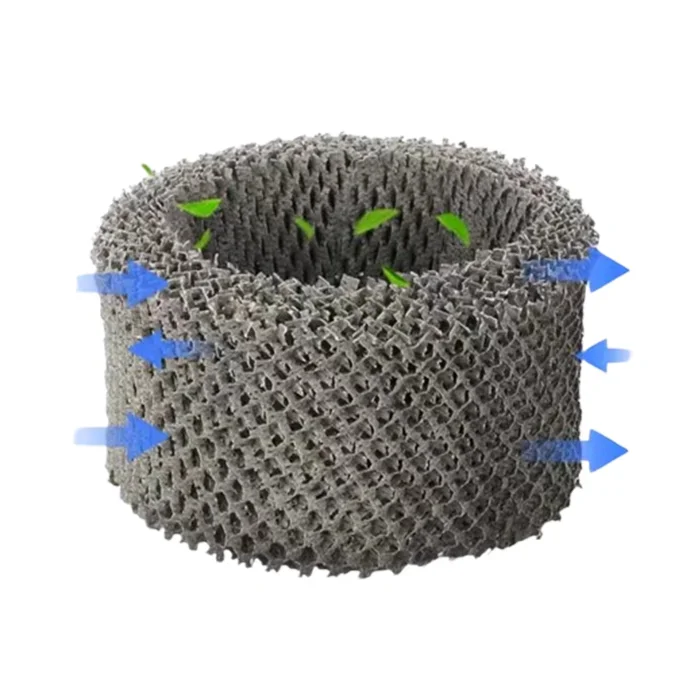

Wood pulp fiber wet film is highly flexible, allowing it to conform to various shapes and contours. This flexibility makes it an ideal choice for applications that require wrapping, folding, or molding. Additionally, the versatility of the material enables its use in diverse industries, ranging from packaging to textiles.

C. Moisture Absorption and Release:

One of the notable properties of wood pulp fiber wet film is its ability to absorb and release moisture. This property is particularly advantageous in packaging applications, as it helps maintain the freshness and quality of perishable goods. The moisture absorption and release capability of the wet film can be further enhanced by incorporating specific additives.

D. Biodegradability and Sustainability:

Wood pulp fiber wet film is an environmentally friendly alternative to traditional packaging materials. It is biodegradable, meaning it can naturally decompose over time, reducing its impact on the environment. Additionally, the use of sustainably sourced wood pulp further enhances the material's eco-friendly credentials.

III. Applications of Wood Pulp Fiber Wet Film

Wood pulp fiber wet film has found widespread applications across various industries due to its unique composition and properties.

A. Packaging:

In the packaging industry, wood pulp fiber wet film is used for food packaging, pharmaceutical packaging, and other consumer goods. Its strength, flexibility, and moisture absorption properties make it an excellent choice for preserving the freshness and extending the shelf life of products.

B. Textiles:

Wood pulp fiber wet film is increasingly being used in the textile industry to create innovative fabrics. The material's flexibility and breathability make it suitable for applications such as sportswear, outdoor clothing, and medical textiles.

C. Construction:

Wood pulp fiber wet film is finding its way into the construction sector as a sustainable alternative to traditional materials. It can be used as a protective barrier, moisture-resistant layer, or even as a binder in composite materials.

D. Other Applications:

The versatility of wood pulp fiber wet film extends to various other applications, including automotive components, medical products, and even art and craft materials.

Conclusion

Wood pulp fiber wet film is a remarkable material with a unique composition and properties that make it highly desirable across multiple industries. Its strength, flexibility, moisture absorption capabilities, and sustainability make it a game-changer in packaging, textiles, construction, and beyond. By understanding the composition and properties of wood pulp fiber wet film, we can fully appreciate its potential and explore new avenues for its application, leading to innovative and sustainable solutions in various sectors.

Wood Pulp Fiber Wet Film: A Breakthrough in Biodegradable Materials

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness