Introduction to 3D Printer Parts

3D printing, also known as additive manufacturing, has revolutionized the way we create objects. This cutting-edge technology allows users to produce custom-designed parts layer by layer from a digital file. While the process itself is fascinating, understanding the parts that make up a 3D printer is essential for anyone involved in 3D printing. Whether you're a hobbyist, a professional, or a business owner, knowing the different 3D printer parts, how they work, and how to maintain them will significantly impact the quality of your printed objects.

This article delves into the key components of a 3D Printer Parts, exploring their functions, importance, and how they contribute to the overall printing process.

Key Components of a 3D Printer

A 3D printer is made up of several critical parts, each serving a unique function in the printing process. Below is an overview of these essential components:

1. Print Bed (Build Plate)

The print bed, or build plate, is the surface on which the 3D printed object is constructed. The quality and material of the print bed are important factors in achieving good adhesion between the object and the bed during the printing process. Print beds can be made of various materials such as glass, aluminum, or flexible materials, with heated print beds becoming increasingly popular for their ability to reduce warping and improve adhesion.

Function:

- Provides a stable surface for the printed object to adhere to.

- Heated beds prevent warping by maintaining a consistent temperature.

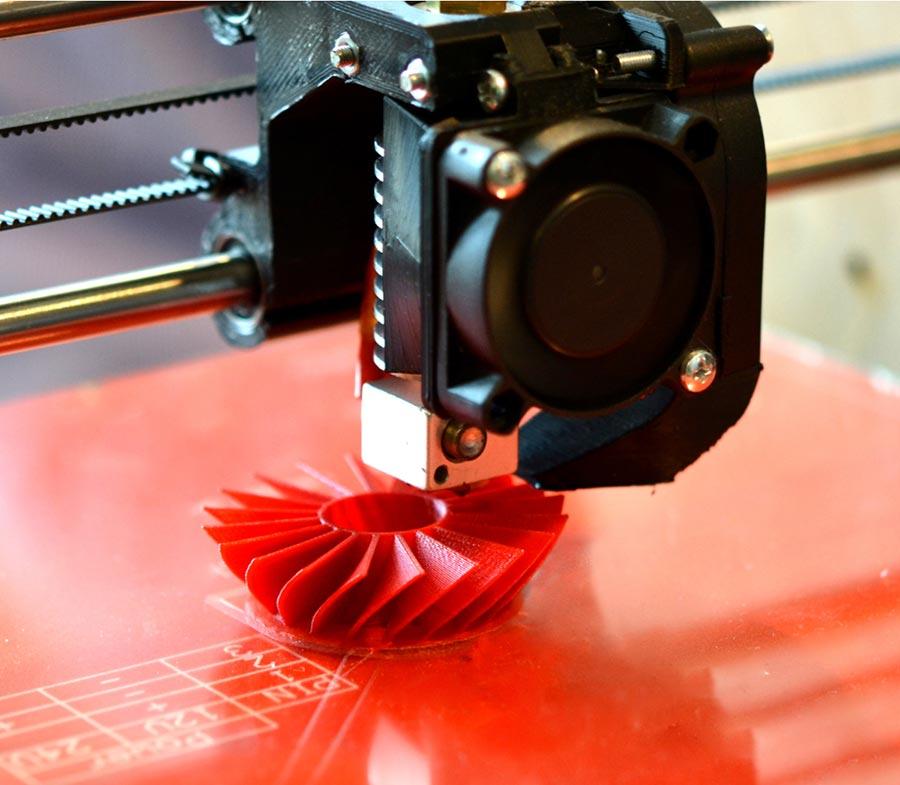

2. Extruder

The extruder is a crucial part of a 3D printer responsible for feeding the filament into the hot end, where it is melted and deposited layer by layer to create the final object. The extruder is composed of two parts: the hot end (or nozzle) and the cold end (where the filament is pushed into the hot end). The cold end of the extruder uses a motor to push the filament into the hot end, while the hot end is responsible for melting the filament.

Function:

- Melts and extrudes filament to build up the 3D object layer by layer.

- Can be either direct drive (extruder located above the print bed) or Bowden (extruder located away from the hot end).

3. Hot End (Nozzle)

The hot end is the part of the 3D printer that melts the filament before it's deposited onto the print bed. It consists of a heated block that maintains a specific temperature to melt various types of filament (such as PLA, ABS, PETG, etc.), as well as the nozzle, which controls the flow of the molten filament.

Function:

- Melts the filament and extrudes it onto the print bed.

- Comes in various sizes, influencing the width and thickness of each printed layer.

4. Step Motors

Step motors are responsible for driving the movements of the printer’s different components. These motors are controlled precisely, allowing for the accurate movement of the print head along the X, Y, and Z axes. There are typically three main stepper motors in a 3D printer: one for the X-axis (horizontal movement), one for the Y-axis (horizontal movement), and one for the Z-axis (vertical movement).

Function:

- Control the movement of the print head and print bed along the X, Y, and Z axes.

- Provide precise, repeatable movements to create accurate 3D prints.

5. Frame

The frame is the structural foundation of a 3D printer, holding all the other components in place. Frames are usually made from materials such as steel, aluminum, or plastic, and they provide stability and rigidity to the printer. A solid, well-built frame is essential for maintaining accuracy and ensuring that the 3D printer operates smoothly during long print jobs.

Function:

- Supports the 3D printer's components and ensures stability during operation.

- Keeps all parts aligned for precise printing.

6. Control Board

The control board, also known as the motherboard, is the central processing unit of the 3D printer. It interprets the G-code (the language used to instruct the printer) and controls the operation of the printer's motors, extruder, and other parts. The control board also interfaces with sensors that monitor the temperature of the hot end and heated bed, ensuring that the printer functions correctly.

Function:

- Controls and directs the operation of the printer’s components, based on the G-code.

- Ensures that the print job progresses smoothly and that temperature settings are maintained.

7. Power Supply

The power supply is responsible for providing electrical power to the various components of the 3D printer. It ensures that the motors, extruder, heated bed, and control board all receive the necessary energy to function properly. The power supply must be compatible with the printer’s voltage and power requirements to ensure safe and reliable operation.

Function:

- Powers the 3D printer’s motors, heated bed, extruder, and control board.

- Must be reliable and able to handle the demands of the printer.

8. Endstops

Endstops are sensors that detect when the moving parts of the 3D printer (such as the print bed or extruder) have reached their physical limits. Endstops help ensure that the printer operates within the desired range of movement and prevent the motors from attempting to move beyond the limits of the printer. They also play a role in the home-positioning process, where the printer's axes are calibrated to a known starting position.

Function:

- Prevents components from moving beyond the printer's physical boundaries.

- Helps with the homing process to calibrate the printer.

9. Cooling Fans

Cooling fans are crucial for controlling the temperature of both the print head (hot end) and the printed object. In particular, cooling fans prevent overheating of the hot end and ensure that the filament cools properly as it is extruded. Cooling is especially important when printing with materials like PLA, which require rapid cooling to avoid warping or other issues.

Function:

- Cools the hot end to prevent overheating.

- Provides adequate cooling to the printed layers, ensuring they solidify correctly.

10. Display Screen

Many modern 3D printers come with an integrated display screen, such as an LCD or touchscreen, which allows users to control the printer’s settings, start or pause print jobs, and monitor the progress of a print in real-time. Display screens can also provide valuable feedback on temperature settings, print status, and error messages.

Function:

- Allows the user to interact with the printer and control its functions.

- Displays real-time information about the print job, such as temperature and progress.

How 3D Printer Parts Work Together

The successful operation of a 3D printer relies on the seamless interaction of all its components. Here’s how the process typically works:

- Preparation: First, a 3D model is created in a CAD software program and then converted into G-code, which is the language the 3D printer understands.

- Material Loading: Filament is loaded into the extruder, which feeds it through the hot end.

- Printing: The stepper motors move the print bed and the extruder along their respective axes, depositing the molten filament layer by layer.

- Cooling and Solidification: As each layer is deposited, the cooling fans ensure that the filament solidifies quickly to maintain the accuracy and quality of the printed object.

- Completion: Once the print is complete, the object is removed from the print bed and any finishing touches are applied.

Conclusion

The parts of a 3D printer are carefully designed to work together in harmony to create intricate and precise objects. From the print bed to the extruder, stepper motors, and control board, each component plays a vital role in ensuring a successful print job. Understanding these components can help you troubleshoot issues, maintain your printer, and optimize your printing process.

As 3D printing technology continues to evolve, the components that make up 3D printers will also advance, offering even greater precision, speed, and versatility for a wide range of applications. Whether you're creating prototypes, custom parts, or artistic designs, knowing your 3D printer's parts and how they function will help you achieve the best possible results.